Solid Carbide Drills - carbide bit

In the field of materials processing, stainless steel machining stands out as a prime method for making a wide variety of industrial parts.

Bronze machining is a technique that is revolutionizing the automotive, marine and electronics industries. Bronze is a copper-based alloy made primarily of copper and tin that offers

Machine turning stainless steel is the ideal method for manufacturing precise cylindrical parts, such as shafts and pins, which are central components in many mechanical and industrial applications.

Are you looking for a stainless steel machining service? Contact our machining company to tell us more about your project.

To get expert advice from a machining specialist, contact HARtech today! Work with our skilled machinists to create the perfect steel parts for your project.

Insert Clearance Angle. 2. Insert Shape. C. M. N*. S. D*. 1. Insert Holding ... *Kennametal standard only. Qualified Surface and Length. Insert IC. 9. Insert.

electric chamfering machineECB-0203 ... ... electric circuit beveler has the capacity from 0 to 3 C x 2R and 3R (mild steel), 0 to 1.5 C x 2R (stainless steel) ...

Stainless steel is the name for a family of an iron-based alloys, composed of 50% iron, at least 10.5% chromium and less than 1.2% carbon. This composition gives it several unique properties.

Drilling is used to create precisely sized holes in stainless steel parts. Drilling is used to manufacture components that will require assembly via bolting or riveting, and components that need spaces for fluids or cables to pass through them.

Each of our doctors has honed the skills and developed expertise in Japan or abroad.We will work closely with you on your concerns.Please feel free to consult with us.

P Jagadeesh · 2023 · 29 — The GFRP composite prepared with hand lay-up method was subjected drilling process by using two types of drills, namely Stub length K10 drill and Brad and ...

The main families of stainless steel include austenitic, ferritic, martensitic, duplex and precipitation-hardened (PH) stainless steel. Each alloy contains variations in its chemical composition, which affects its mechanical properties and resistance to corrosion.

Stainless steel can be used to create machined parts of exceptional quality, as it is a metal alloy that offers an ideal combination of precision and strength. It is available in a variety of grades, meaning professionals can select an appropriate type of stainless steel according to the specific requirements of their industry.

We are a fully stocked Honda, Kawasaki, Suzuki, KTM, Polaris, Can-am, Ski-Doo, Sea-Doo and Timbersled dealership located in Ontario, Oregon.

Stainless steel machining can be carried out using different techniques, including milling, turning, screw machining and drilling. Each method has advantages and disadvantages in terms of accuracy, speed, and cost.

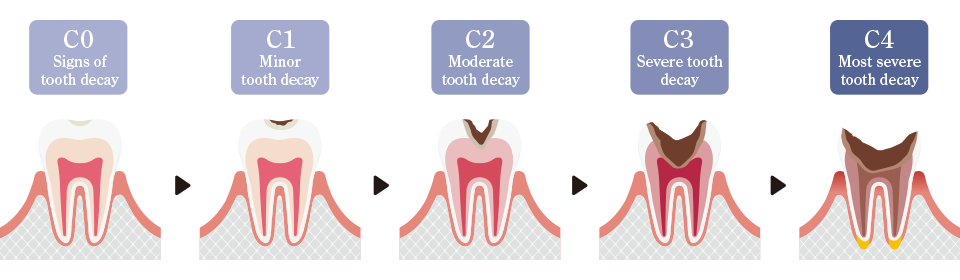

C3 is a cavity that has reached the pulp of the tooth. The nerve of the tooth has been affected and this causes severe pain. The pain can be induced by hot as well as cold and sweet foods. A spontaneous pain called “zing zing” may occur even at rest. The treatment is completed by removing the nerve of the tooth, performing a root canal, and fabricating and fitting a covering.

Machining stainless steel presents unique challenges, due to both its composition and its unique physical properties. For example, stainless steel tends to generate more heat during processing, which can lead to the deformation of parts or premature wear of tools.

Plastic machining is a manufacturing technique that is key to modern industry, particularly in the automotive, aerospace, electronics and medical sectors. Unlike metals, plastics offer unrivalled lightness,

− Cutting Edge Diameter. The width of the bit at the widest point of the cutting edge. This is used to determine the size of the hole that will be.

AISI 304L is one of the most popular grades of stainless steel, prized for its versatility and resistance to corrosion. It is widely used o create structural components, and in food processing equipment, storage tanks and cookware.

One of the most notable characteristics of stainless steel is its high resistance to corrosion, which makes it a preferred choice for applications in contexts where there is a high likelihood of this type of wear, such as the chemical and food industries.

C2 is a dentin cavity. The holes in the tooth surface tend to be relatively deep and large. Cold and sweet foods can induce a “toothache”. After the lesion is shaved, treatment is completed with the fabrication and application of a filling or cover.

Y Xia · 2024 · 3 — A notable discovery was the augmentation of LCE's tensile strength by eight times upon amalgamation with carbon fiber fabric. Moreover, distinct ...

55210 — Surrey Central Station @ Bay 2. Realtime ×. Schedule. Trip, Sched, Corr ↓, Delay, Wait, Block, Vehicle. 501 Langley Centre, 11:03. 11:05. -2½. 54 min ...

Free CNC Speed and Feed Calculator allows CNC Machinists and CAD/CAM Programmers to calculate milling and drilling speeds and feeds for a wide variety of ...

Once adults lose our teeth, they never return to their original state. Not only they are dissolved by acid produced by bacteria in the mouth, but tooth structure removed by cavity treatment will not regenerate. For this reason, early detection and treatment of tooth decay is of utmost importance.

Similarly, stainless steel is also used in the aerospace sector to make critical components and mechanical parts, including turbines and fuselage structures. It is highly valued for being lightweight, weldable and machinable.

C4 is the terminal stage of tooth decay. The crown, which is the head of the tooth, collapses and only the root of the tooth remains. Because the nerve is dead, you won’t feel any pain. In most cases, when it has progressed to this point, tooth extraction is indicated. Once the tooth has been extracted, the missing tooth is replaced with a prosthetic, such as a bridge, denture or implant.

In this article, our industrial machining experts introduce you to stainless steel machining, and explain how to overcome the challenges of machining this metal using the right knowledge and techniques.

Selecting the right tools is key to creating high-quality, precise stainless steel parts. The machining equipment itself must also be made from high-quality materials in order to withstand the thermal and mechanical stresses associated with machining stainless steel.

The sooner you find cavities, the less we would cut the tooth structure. In particular, we focus on conservative treatment with as little cutting as possible. We strive to preserve as much of the patient’s own teeth as possible and minimize damage.

However, working with stainless steel also poses many challenges, as it has unique properties that set it apart from other metals.

C1 is a cavity in the enamel. It is a relatively shallow hole on the tooth surface. It does not cause pain at this stage, but in some cases, cold objects may sting. The treatment is completed by drilling away the bacterial-infested tooth structure and filling it with a composite resin.

MATERIAL. SPEED. END MILL DIAMETER FEED PER TOOTH (INCHES). (SFM). UP TO 1/4. UP TO 1/2. UP TO 1. ALUMINUM/ALUMINUM ALLOYS. 600 – 1300 .0002-.002.

AISI 316L or low-carbon 316 stainless steel offers even higher resistance to corrosion than 304L stainless steel because it contains molybdenum. This grade is commonly used in highly corrosive and saline environments such as are common in the chemical and marine industries.

Shop by Category Woodruff Keyseat Cutters Cutting Tools/End Mills/Woodruff Keyseat Cutters Viewing Page 1 of 29 (288 results)

Cast iron machining is widely used in the industrial sector in the manufacture of machined parts and mechanical components, and in machine tooling. Cast iron is a

In addition, professional machinists must adjust all parameters, including cutting speed, depth of passage and feed, to optimize performance and extend tool life.

In addition, stainless steel has a high resistance to elevated temperatures, which means it can be welded and yet remain suitable for use in situations where it will be exposed to extreme temperatures.

C0 is an early stage of tooth decay and does not involve holes in the tooth surface. The only characteristic of this stage is the development of “white stains” described as white spots or cloudiness. There is no need to drill the teeth, and fluoride is applied to promote remineralization. You will be advised how to brush so as to improve your hygiene.

Also, its relatively low malleability can make the machining process more difficult than for metals with higher elasticity.

Milling is one of the most popular machining techniques overall, and is often used when working with stainless steel. This method is recognized for being excellent for industrial machinery design, which involves high levels of complexity and precision. In the world of stainless steel machining, milling occupies a prominent place, as it makes it possible to meet strict requirements related to both quality and durability.

Stainless steel is used in a variety of industrial sectors, including medical, aerospace, food and beverage, and shipbuilding. Machined stainless steel parts for medical use are widely used to make surgical instruments and orthopedic implants, as this material is biocompatible, malleable and resists stress and corrosion.

Since the composition of stainless steel can vary, its characteristics can vary as well, including its mechanical properties and level of resistance to corrosion. Nickel enhances the physical properties of stainless steel, while titanium and molybdenum increase its strength and resistance to corrosion.

There are several families of stainless steel, each with unique characteristics. Each type is more or less suited to different types of heat treatment for specific applications.

0086-813-8127573

0086-813-8127573