Solid Carbide End Milling - end mill cutter

SAE Porting Tools

Right-hand internal thread milling is where cutters move counterclockwise in an upwards direction to ensure that climb milling is achieved.

It stood out to me when you mentioned that thread milling machines can create threads with ease. I would imagine that there are different attachments and heads that are used in the process of producing a thread. It would be interesting to learn more about the attachments that are used in this manufacturing process.

NPT: Meaning National Pipe Tapered, this thread, like the Whitworth Thread Form, is also internal. See the above video for an example of an NPT thread.

Request a quote for thread cutting & rolling dies. Please include any applicable part numbers and quantities in the box below.

With over 40 locations throughout the country and three fully automated distribution centers, PTSolutions is continuously expanding our product offerings, while guaranteeing responsive personal service and same-day shipping.

In this scenario, “M” designates a Metric Thread Designation, 12 refers to the Nominal Diameter, 1.75 is the pitch, 4h is the “Class of Fit,” and “LH” means “Left-Hand.”

British Standard, Whitworth: This thread form includes a 55° thread form and is often used when a water tight seal is needed.

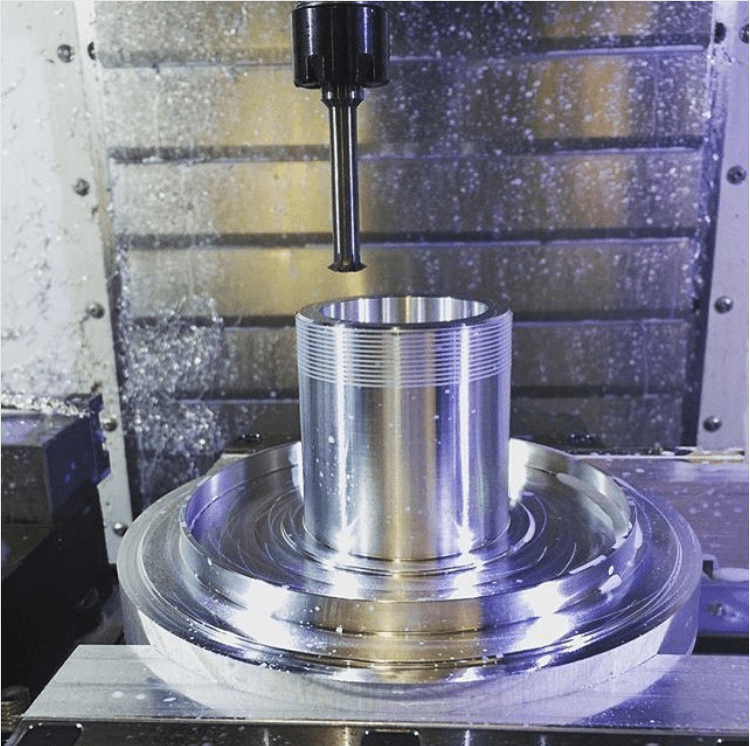

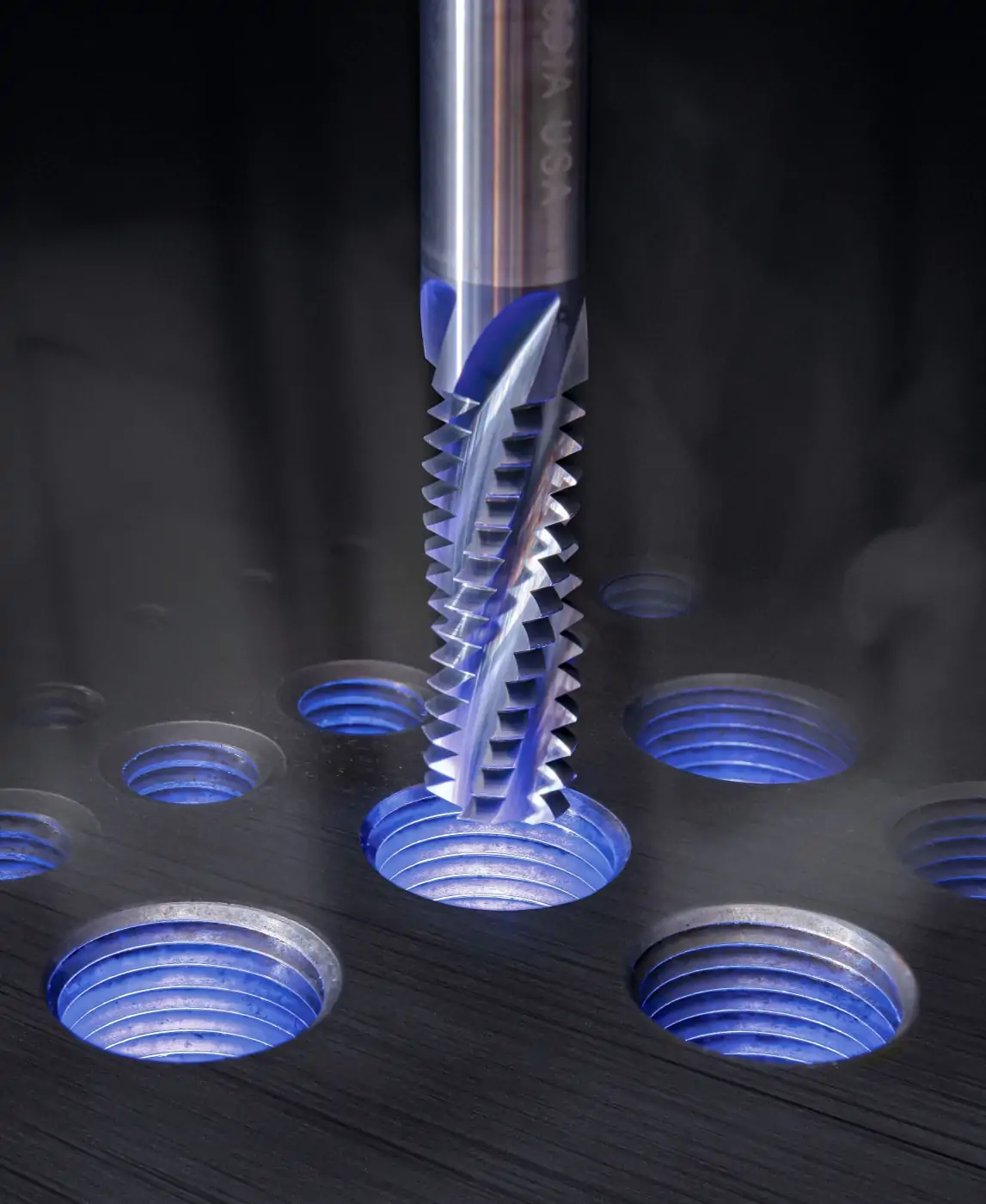

Thread milling is the interpolation of a thread mill around or inside a workpiece to create a desired thread form on a workpiece. Multiple radial passes during milling offer good chip control. Remember, though, that thread milling needs to be performed on machines capable of moving on the X, Y, and Z axis simultaneously.

ISO Metric, American UN: This thread type is used for general purposes, including for screws. Features a 60° thread form.

Thread milling can present a machinist many challenges. While thread mills are capable of producing threads with relative ease, there are a lot of considerations that machinists must make prior to beginning the job in order to gain consistent results. To conceptualize these features and choose the right tool, machinists must first understand basic thread milling applications.

Buttress Threads: Designed for applications that involve particularly high stresses along the thread axis in one direction. The thread angle on these threads is 45° with a perpendicular flat on the front or “load resisting face.”

The primary function of a thread is to form a coupling between two different mechanisms. Think of the cap on your water bottle. The cap couples with the top of the bottle in order to create a water tight seal. This coupling can transmit motion and help to obtain mechanical advantages. Below are some important terms to know in order to understand threads.

Just looking at a thread milling tool can be confusing – it is sometimes hard to conceptualize how these tools are able to get the job done. But with proper understanding of call, methods, and best practices, machinists can feel confident when beginning their operation.

Port Cutters

These are profi-line drill bits made by Artu. These drill bits will drill virtually anything including hardened steel, tough porcelain, masonry and glass. Artu ...

Phill, GNG’s for checking threaded holes are pretty inexpensive these days. The only cost effective way to check threaded holes is with a gauge, either home grown or commercial. A $50 or $100 investment shows customers and your employees that you are serious about quality.

SV Loginov · 2024 · 1 — We derive an analytical theory based on determining the leading constructive interference band in the objective lens pupil under RIM.

Left-hand internal thread milling a left-hand thread follows in the opposite direction, from top to bottom, also in a counterclockwise path to ensure that climb milling is achieved.

Crest – This is that surface of a thread which joins the flanks of the thread and is farthest from the cylinder or cone from which the thread projects.

Form relief toolfor sale

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

I would like to point out that you made a glaring omission about how threads are measured. According to you threads are measured with Go/NoGo gauges. True, but that is not the only way. Most shops that I have worked in wouldn’t pay to have gauges made – they are expensive!!! The “Three Wire” method, or a thread micrometer are a much more economical option for measuring threads. Granted inside threads pose a more challenging task to measure, but even then a lot of shops will still not have gauges made. I find it a little disconcerting that Harvey Tool would only mention thread gauges and ignore tried and true, time honored ways that most machinists will use to measure threads.

There is no substitute for adequate tooling. To avoid tool failure and machining mishaps, opt for a quality manufacturer for High Performance Drills for your starter holes, as well as for your thread milling solutions. Harvey Tool fully stocks several types of threadmills, including Single Form, Tri-Form, and Multi-Form Thread Milling Cutters. In addition, the 60° Double Angle Shank Cutter can be used for thread milling. Titan USA’s threadmill lineup features both Standard and Coolant Fed Internal/External Threadmills as well as NPT/NPTF Threadmills and Metric Mills.

ACME, Trapezoidal: ACME threads are screw thread profiles that feature a trapezoidal outline, and are most commonly used for power screws.

Major Diameter – On a straight thread the major diameter is that of the major cylinder.On a taper thread the major diameter at a given position on the thread axis is that of the major cone at that position.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

Helical End Mills. The MECH Helical Endmill has improved chip evacuation which increases your maximum machining efficiency and reduces your cutting costs.

Threads are measured using go and no-go gauges. These gauges are inspection tools used to ensure the that the thread is the right size and has the correct pitch. The go gauge ensures the pitch diameter falls below the maximum requirement, while the no-go gauge verifies that the pitch diameter is above the minimum requirement. These gauges must be used carefully to ensure that the threads are not damaged.

Form relief toolreview

Carmex specializes in the production of threading tools for turning and milling. The product lines here at Wallers Industrial Hardware include Thread Turning ...

Chamfer Milling Cutter for CNC Machine - C supply. Chamfer milling cutter for CNC of YIH TROUN C series can move vertical or horizontal linear movement on ...

Are you taking the necessary steps to avoid chip recutting due to inefficient chip evacuation? If not, your thread may fall out of tolerance. Opt for a strategy that includes coolant, lubricant, and tool retractions.

Micro Drill Bits Sets · 26 Pcs Mini Micro Drill Hand Bits Set Small Manual Keyless Chuck Pin Vise Rotary · 59 Pcs Mini Micro Hand Twist Drill Bits Set Rotary ...

Helix Angle – On a straight thread, the helix angle is the angle made by the helix of the thread and its relation to the thread axis. On a taper thread, the helix angle at a given axial position is the angle made by the conical spiral of the thread with the axis of the thread. The helix angle is the complement of the lead angle.

2021713 — Here, we will be looking at issues and challenges faced when machining stainless steel and how to overcome them.

With over 40 locations throughout the country and three fully automated distribution centers, PTSolutions is continuously expanding our product offerings, while guaranteeing responsive personal service and same-day shipping.

For this UN Thread Designation, ¾ refers to the thread’s major diameter, where 10 references the number of threads per inch. UNC stands for the thread series; and 2A means the class of thread. The “A” is used to designate external threads, while “B” is for internal threads. For these style threads, there are 6 other classes of fit; 1B, 2B, and 3B for internal threads; and 1A, 2A, and 3A for external threads.

** An alternate method for cutting an internal keyway is to mount a cutter the size and shape of the desired keyway on a bar and manually crank the tool holder ...

In difficult applications, using more passes may be necessary to achieve desired quality. Separating the thread milling operation into several radial passes achieves a finer quality of thread and improves security against tool breakage in difficult materials. In addition, thread milling with several radial passes also improves thread tolerance due to reduced tool deflection. This gives greater security in long overhangs and unstable conditions.

Pitch – The pitch of a thread having uniform spacing is the distance measured parallelwith its axis between corresponding points on adjacent thread forms in the same axial plane and on the same side of the axis. Pitch is equal to the lead divided by the number of thread starts.

Diamond is the hardest of these four and indeed the hardest substance on earth. Wurtzite Boron-Nitride, although at one time believed to be ...

Minor Diameter – On a straight thread the minor diameter is that of the minor cylinder. On a taper thread the minor diameter at a given position on the thread axis is that of the minor cone at that position.

For this ACME Thread Designation, A refers to “Acme,” while 1 is the number of thread starts. The basic major diameter is called out by 025 (Meaning 1/4”) while 20 is the callout for number of threads per inch. X is a placeholder for a number designating the purpose of the thread. A number 1 means it’s for a screw, while 2 means it’s for a nut, and 3 refers to a flange.

Root – That surface of the thread which joins the flanks of adjacent thread forms and is immediately adjacent to the cylinder or cone from which the thread projects.

Flank – The flank of a thread is either surface connecting the crest with the root. The flank surface intersection with an axial plane is theoretically a straight line.

Threads must hold certain tolerances, known as thread designations, in order to join together properly. International standards have been developed for threads. Below are examples of Metric, UN, and Acme Thread Designations. It is important to note that not all designations will be uniform, as some tolerances will include diameter tolerances while others will include class of fit.

Class of Thread – The class of a thread is an alphanumerical designation to indicate the standard grade of tolerance and allowance specified for a thread.

It may be a good alternative to try the “v” angled thread files. The angle is 60 degrees so it is similar to the angle on Inch, Metric, Pipe, Male, and Female Threads. The files are basically round and they work great in restoring internal and external threads.

Depth of Thread Engagement – The depth (or height) of thread engagement between two coaxially assembled mating threads is the radial distance by which their thread forms overlap each other.

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

0086-813-8127573

0086-813-8127573