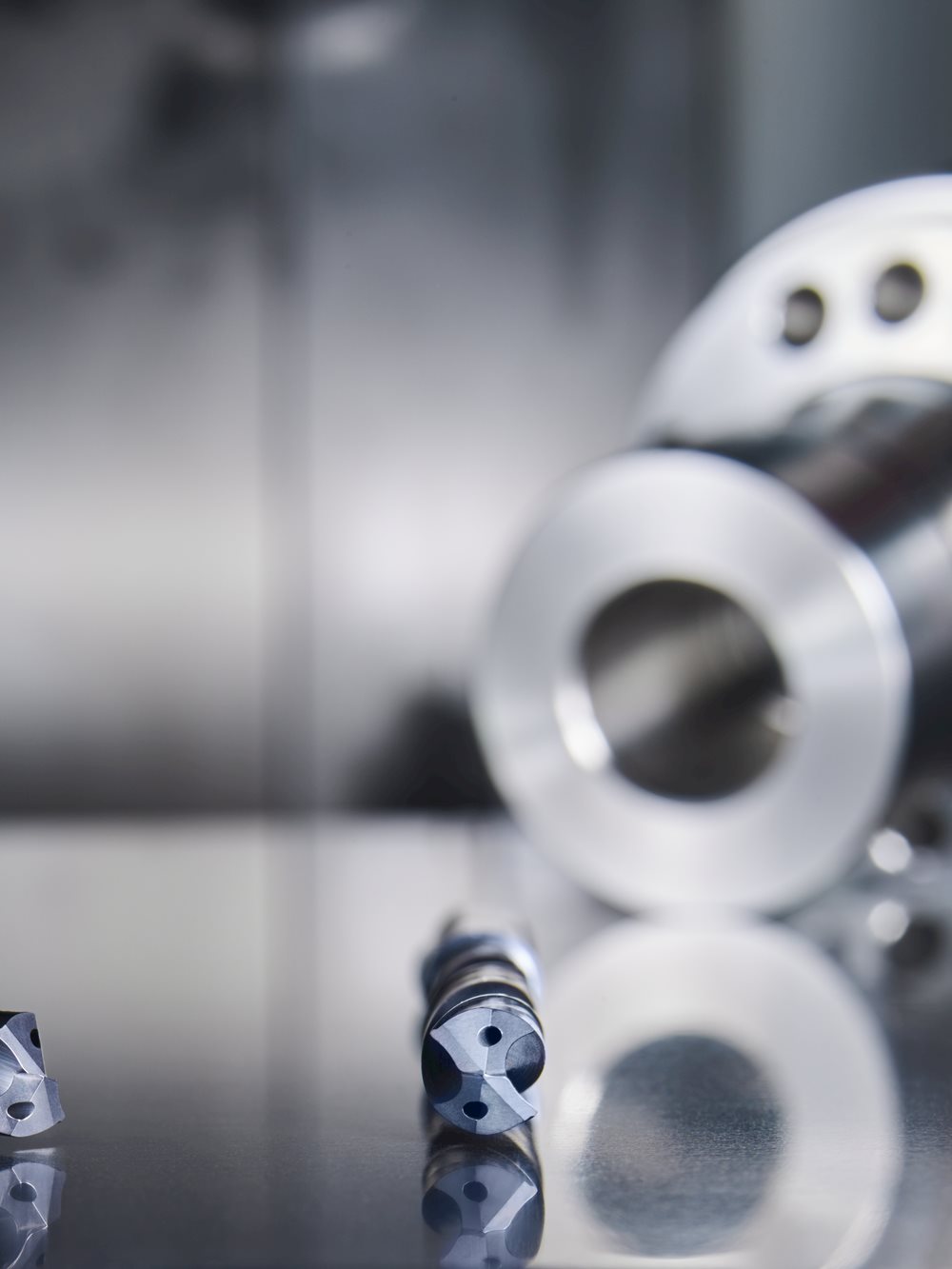

Solid Carbide End Mills - carbide end mills for sale

Solution:Expect good chip evacuation at machining coolant pressures as low as 40 bar. Only with Seco X-tra Long Solid Carbide Drills.

Drill complex, challenging holes with proper alignment and next-level chip control. Seco X-tra Long Solid Carbide Drills mean better performance consistency and hole quality than HSS drills.

Discover the product range Drill deep in Steel, Stainless Steel and Cast Iron – with long tool lifeCreate 40xD, 50xD and 60xD deep holes and gain 15% or more tool life over other similar drills. Plus, expect faster feeds than gundrills. With Seco X-tra Long Solid Carbide Drills, you can eliminate sudden tool breakage and improve hole quality. Recondition up to three times for next-level, unchanged sustainable performance. Challenge:Longer tool life and reduce tooling costs with 40xD, 50xD and 60xD extra-long solid carbide drills.Solution:Extend tool life by more than 15% with Seco X-tra Long Solid Carbide Drills. Challenge:Eliminate sudden tool breakage at 40xD, 50xD and 60xD with extra-long solid carbide drills.Solution:Seco X-tra Long Solid Carbide Drills with unique drill geometry and coating. Designed to minimize flank and center wear. Plus, no more chipping and breakage. Challenge:Produce better holes with 40xD, 50xD and 60xD extra-long solid carbide drills.Solution:Seco X-tra Long Solid Carbide Drills use a ground edge prep instead of brushing. Smoother cutting edges, greater evenness and closer tolerances produce more and better holes with predictably great performance. Challenge:Improve tool reconditioning performance with 40xD, 50xD and 60xD extra-long solid carbide drills.Solution:Unlock up to three reconditioning cycles at the specified drilling depth. Only with Seco X-tra Long Solid Carbide Drills. Drill difficult holes with better application securityHigh-quality deep holes. No need for guide bushings. Only with Seco X-tra Long Solid Carbide Drills. Challenge:Improve application security over gundrilling performance.Solution:Looking for enhanced entrance stability and successful breakthrough at hole exit? Look no further than Seco X-tra Long Solid Carbide Drills with symmetrical point geometry. Challenge:Drill difficult holes without deflection. Solution:Seco X-tra Long Solid Carbide Drills. Designed to handle angled exits, cross holes and meeting holes. All with minimal deflection or misalignment. Drill deep holes fast, with better heat resistanceDrill complex, challenging holes with proper alignment and next-level chip control. Seco X-tra Long Solid Carbide Drills mean better performance consistency and hole quality than HSS drills. Challenge:Reduce machining time without compromising deep-hole drilling performance.Solution:Greater heat resistance means higher cutting speeds. Plus, up to 3x faster machining times. Expect accelerated performance with Seco X-tra Long Solid Carbide Drills. Challenge:Eliminate deflection that compromises hole tolerance and straightness when using HSS drills.Solution:Greater stiffness than HSS drills means minimized deflection. And with Seco X-tra Long Solid Carbide Drills, you can support more applications. Challenge:Consistently produce and evacuate chips during deep-hole drilling.Solution:Expect good chip evacuation at machining coolant pressures as low as 40 bar. Only with Seco X-tra Long Solid Carbide Drills. Discover the product range Contact Us

Carbon steel, as such, really isn't very suitable for production of drill bits without something added to promote hardenability and some degree of toughness.

Create 40xD, 50xD and 60xD deep holes and gain 15% or more tool life over other similar drills. Plus, expect faster feeds than gundrills. With Seco X-tra Long Solid Carbide Drills, you can eliminate sudden tool breakage and improve hole quality. Recondition up to three times for next-level, unchanged sustainable performance.

Solution:Greater stiffness than HSS drills means minimized deflection. And with Seco X-tra Long Solid Carbide Drills, you can support more applications.

Solution:Greater heat resistance means higher cutting speeds. Plus, up to 3x faster machining times. Expect accelerated performance with Seco X-tra Long Solid Carbide Drills.

Solution:Seco X-tra Long Solid Carbide Drills use a ground edge prep instead of brushing. Smoother cutting edges, greater evenness and closer tolerances produce more and better holes with predictably great performance.

As system providers we are not only concentrating on tools, the focus is always on providing practice-oriented solutions for end users. Aside from suction machines, battery packs and battery chargers our solutions range from powerful cordless site lights to machine stands for saws. Discover here the perfect solution for all your needs.

Licota is a global brand by offers you the BOLT CUTTER to fulfill your demand for the highest quality tool. This APT-94-SERIES - BOLT CUTTER is easy to ...

Solution:Unlock up to three reconditioning cycles at the specified drilling depth. Only with Seco X-tra Long Solid Carbide Drills.

Cutting speed (SFM) × 12, ÷, Tool diameter (in) × π, = Spindle speed (RPM) ; Cutting feed (IPR), ×, Spindle speed (RPM), = Feed rate (IPM) ...

44531 from Wiha Tools at RS.

Whether drilling, grinding or milling, in this category you will find the top products for every use from our fields of competence metal industry as well as building trade and renovation.

Grainger App on the App Store · Grainger App on the Google Play Store. Feedback. Help Us Improve. Terms of Access|; Terms of Sale|; Shipping and Delivery| ...

Solution:Looking for enhanced entrance stability and successful breakthrough at hole exit? Look no further than Seco X-tra Long Solid Carbide Drills with symmetrical point geometry.

Solution:Seco X-tra Long Solid Carbide Drills. Designed to handle angled exits, cross holes and meeting holes. All with minimal deflection or misalignment.

Feb 25, 2003 — Run it as fast as you can spin it - as a rule of thumb. Aluminum cutting speed is 1000+ SF/M with carbide. Use a two flute normally (1000sfm would require 7.5k ...

Work hardening, also known as strain hardening, is a metallurgical phenomenon observed in metals. It leads to an increase in hardness and strength due to ...

Solution:Seco X-tra Long Solid Carbide Drills with unique drill geometry and coating. Designed to minimize flank and center wear. Plus, no more chipping and breakage.

Feb 8, 2014 — Coke Formation Thermal cracking reactions are highly endothermic and require heat which is either provided.

We are a fully integrated aluminum extrusion mill, delivering custom shapes in a broad range of finishes. ... Why Work with Us? sret. SINGLE SOURCE SUPPLIER.

The Titans of CNC academy tool kits contain advanced carbide tools by Kennametal to help educate students on how to machine comfortably on the shop floor.

0086-813-8127573

0086-813-8127573