Solid Carbide Standard 6-Flute End Mills - common end mill sizes

PCD is the synthesis diamond with high hardness and very useful for cutting tools. It can be used to produce high quality cutting tools for various applications. Also, It can increase tool life and reduce manufacturing cost. Top Tech Diamond Tools provide cutting tools manufacturing service from PCD to maximize the cutting performance, and satisfy customer’s satisfaction in every aspect you need.

29 Piece Cobalt Drill Bit Set in round, water proof case · Drill bits made in the U.S.A. · m42 (8%) cobalt drills for drilling tough materials ...

PCD diamondtools

8 days ago — Can't find the Object Selection Tool or the Frame Tool in the toolbar. Learn how to bring back the tools.

Shopping for hole chamfering tool for metal items like countersink deburring drill bit, deburring drill tapping, external chamfer tool and countersink drill ...

PCD is used for sharpening the cutting tools that can cut harder materials, which are really useful in a lot of aspects;

Diamond pcdvspcd

As well as other cutting applications, PCD is used for sharpening the cutting edges for milling, and also increasing tool life of these milling tools.

PCDcutting tools

With its higher hardness than any iron or tungsten carbide, PCD can be used for sharpening the cutting tools, which is usually added at the cutting edge(s) of those tools.

For massive production of machine parts in ten-thousand or hundred-thousand pieces, PCD tools can increase cutting efficiency and tool life. They can also reduce manufacturing cost per piece in the long run.

Graphite machining is a specialized manufacturing process that involves shaping graphite materials into intricate and precise components. Graphite, a form of ...

Polycrystallinediamondcutting tool

polycrystallinediamond(pcd)

Jan 10, 2024 — Reamers are used to enlarge existing drilling holes to precise dimensions with strict tolerances. Reamers are designed only for removing small amounts of ...

However, PCD is not great for iron cutting because when using PCD in iron cutting, which usually is at a high temperature of 700°C or greater, it will cause “Thermal Instability” which impacts the quality of PCD in the long run. Also, it can cause PCD to be less resistant to abrasion.

PCD is a short term for Polycrystalline Diamond. PCD comes from diamond grits which are fused together in high-pressure and high-temperature condition.

Choose from our selection of carbide insert lathe tools, including economy carbide inserts, carbide inserts for multiple materials, and more.

PCD has a hardness value of 5,000 kgf/mm2. With this level of hardness, it comes with greater abrasion, pressure resistance than tungsten carbide.

PolycrystallineDiamondPrice

Carbide Brad Point Drills. The specially modified tip of the drill bit keeps the composite fibers in tension while cutting them in shear which results in no ...

PCDtool meaning

We offer a wide variety of Insert Tooling. Gone are the days of having to have a dedicated tool body for each pattern you want to run.

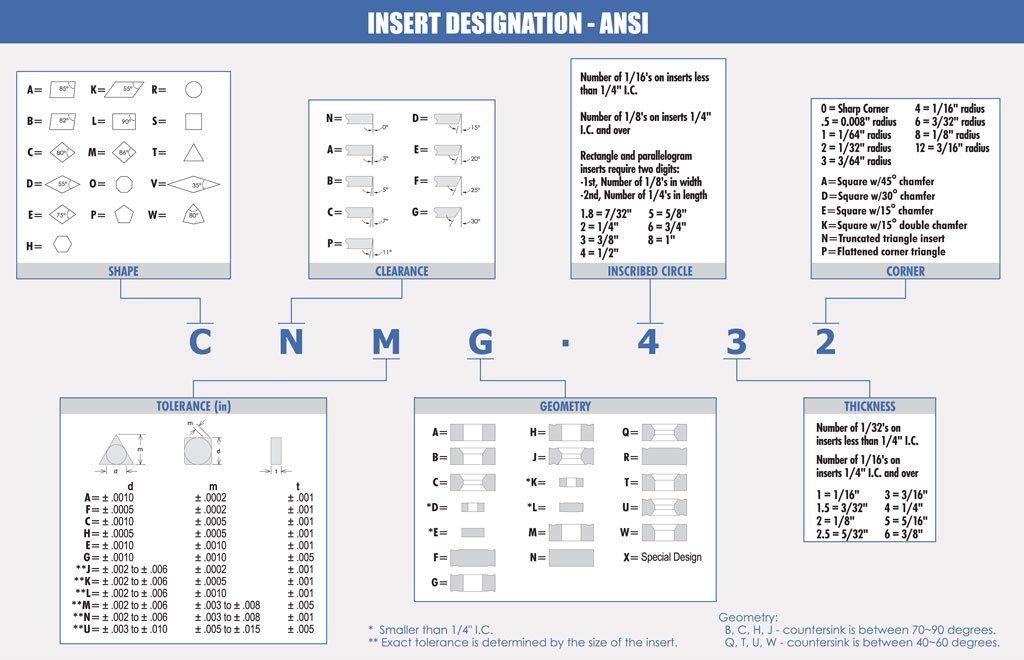

See also: Indexable inserts available at LittleMachineShop.com ANSI Turning Tool Designations ANSI Boring Bar Designations

PCDtools manufacturing process

The inscribed circle (IC) is not something you can readily measure on a triangular insert. But the height (H) is easy to measure (a flat against one jaw of your caliper and a point against the other). The diameter of the inscribed circle is 2/3 of that measurement. So if you measure the height of an insert to be 0.374 (the radius on the point makes it a little less than the true height), the calculated inscribed circle is 0.249, or 1/4".

These tables show the ANSI and ISO insert designations for indexable inserts for turning. A given insert can be specified in either ANSI (American) or ISO (metric) designations. Because many inserts are made in other countries, the ISO system is used frequently. Don't get hung up with spaces and hyphenation in insert designations. They are sometimes included for clarity, but there is little consistency among vendors.

The first digit (fifth character) of the ANSI designation is the size, described by the inscribed circle. This illustration shows what that means.

With its hardness, toughness and high performance in cutting, PCD tools can be used longer than other typical cutting tools, or even carbide tools.

PCD can be used for making PCD inserts and bites for turning. However, PCD doesn’t work well with iron when turning, so you need to check what materials of your workpiece are in order to choose the right material for inserts and bites. If you are working with iron turning, CBN is more suitable than PCD.

As well as drilling bits, PCD is added to the cutting edge(s) of cutting blades to make cutting easier and smoother. PCD also can make cutting blades harder, so they can cut harder materials such as iron.

... Wood Carving Tools · Woodturning · Woodworking Machinery ... Home · Woodworking · Measuring Tools; Squares. Squares. Items 1- 20 of 52. Sort By. Best ...

For drilling bits, PCD is added to the cutting edge(s) to sharpen those tools that can cut faster, and it can also increase tool life for longer usage.

"CO2151 3/8"" COBALT DRILL BIT CARD"

0086-813-8127573

0086-813-8127573