Solid carbide up & downcut spiral bits 190 - spiral cut bits

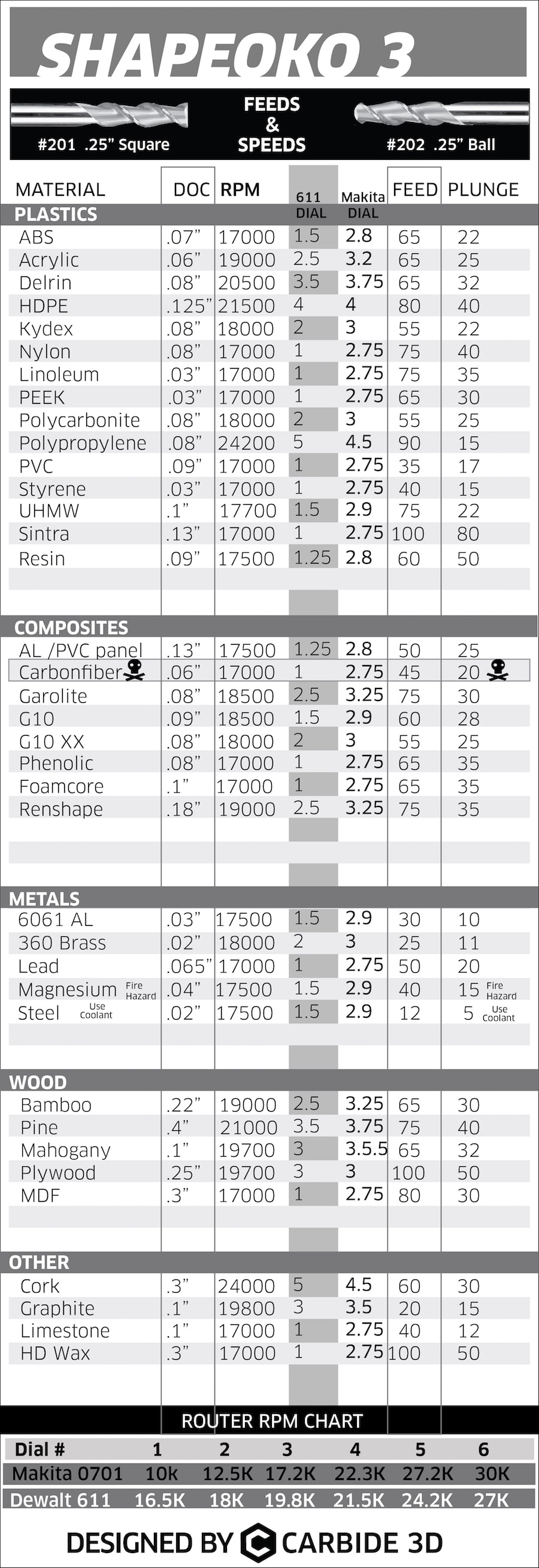

Milling speeds and feeds chartpdf

Carbide end Mill RPMchart

The search system allows you to search for content inside of the following structures: Products, Categories, Focus On

Milling speeds and Feeds chartMetric

All 3D Printing CNC Deals Featured Makers Fiber Laser Laser Onefinity Patreon Podcast Shipping Shop Tour The Build Guild Podcast Tools T-Shirts Tundra VR Woodworking Projects

November 2023 June 2023 November 2022 August 2022 January 2022 November 2021 October 2021 March 2021 February 2021 January 2021 December 2020 November 2020 October 2020 September 2020 July 2020 June 2020 May 2020 April 2020 March 2020 February 2020 January 2020 November 2019 October 2019 September 2019 August 2019 July 2019 June 2019 May 2019 April 2019 March 2019 February 2019 January 2019 December 2018 October 2018 September 2018 August 2018

Aluminummillingspeedchart

For full details of our offering, check out the technical datasheets of our end milling machines to find the model that best matches your needs.

Regardless of the angle of the V-bit, it will only cut to the depth required to cut to the width of what is being carved. If you are carving something wider than the bit diameter you can go up to the DOC of the bit.

Elumatec end milling machines are the ideal machine tools for milling doors and transom profiles, in either PVC or aluminium. The manual feed routing unit, the large cutting range and the facility to use basic tools or accessories are just some of the characteristics of these machines.

The offering of Elumatec end milling machines includes an assortment of models that differ in terms of height and air consumption; all the products offer exceptional flexibility thanks to the horizontal and vertical pneumatic clamping units. Continuous machine customisation thanks to the facility to change the orientation necessary for the material stop, designing right and left acute angles. Precise, smooth action and low-wear recirculating ball guides. Ease of use is guaranteed by the tools quick change system and the spindle lock to facilitate tool changes.

What max depth of cut do you do on those V-bits bits per pass? I have those exact 60 and 90 degree bits and get a very ugly cut on the bottom (think about something between tear-out and a fuzzy bottom) unless I slow it WAY down.

0086-813-8127573

0086-813-8127573