SONORA: Growth Marketing | Web Development | Branding - sonora core marketing inc

By the way, this calculation is not just for thread milling, but can be used in any application where feed-per-minute is used, and the toolpath makes small radial motions.

We're professional CNC tungsten carbide turning insert suppliers in China, specialized in providing high quality customized products.

For external right-hand threads, program the helical interpolation direction with clockwise arcs (G02), with the Z-axis starting above the deepest point, and feeding down (Z negative) by the amount of the pitch of the thread. For external left-hand threads, program the helical interpolation direction with clockwise arcs (G02), with the Z-axis starting at the deepest point, and feeding up (Z positive) by the amount of the pitch of the thread.

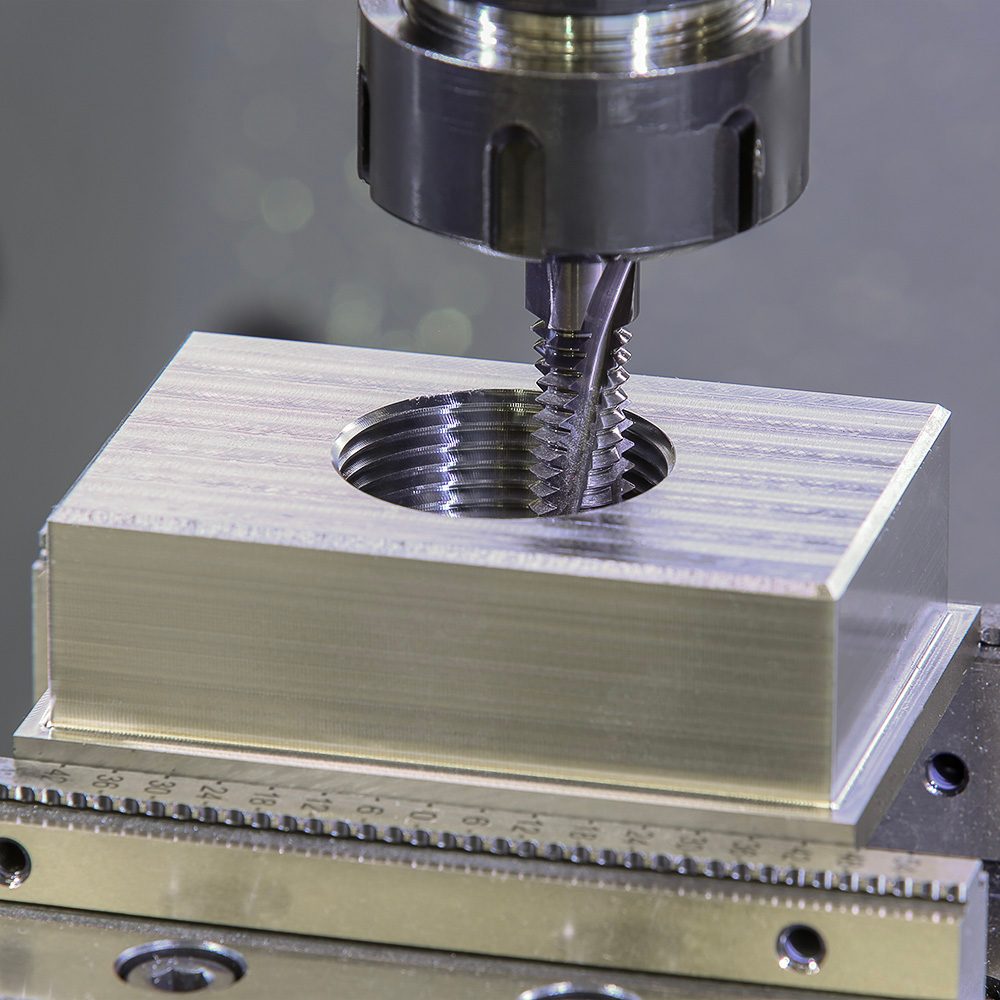

Always program the spindle in the forward direction (M03). For internal right-hand threads, program the helical interpolation direction with counterclockwise arcs (G03), with the Z-axis starting at the deepest point, and feeding up (Z positive) by the amount of the pitch of the thread. For internal left-hand threads, program the helical interpolation direction with counterclockwise arcs (G03), with the Z-axis starting above the deepest point, and feeding down (Z negative) by the amount of the pitch of the thread.

Company profile page for Harveys Industries Inc including stock price, company news, executives, board members, and contact information.

Always program climb milling for better surface finish and improved tool life. Climb milling generates less heat and less tool deflection, which leads to vibration.

These tools are titanium aluminum nitride (TiAlN) coated, solid carbide cutters with cylindrical shanks, and they feature a hole through the center of the tool to take advantage of through-tool coolant.

Jan 16, 2008 — You can use just carbide tools but there is tooling available just for graphite. It basically turns to powder when you machine it, you will want to have a ...

Reviews from some of our clients who rank TTP HARD drills as the best cobalt drill bits for drilling harder metals including stainless steel.

The feedrate when thread milling is very important. You should not use the same calculated feed-per-minute feedrate as you would for an endmill cutting in a straight line. Because the tool path of a thread mill is typically a very small radius, the outer cutting edges are traveling much faster relative to the center of the cutter. The term “faster” may be misleading; I should say, the edge is traveling much farther in the exact same amount of time. Therefore, we need to perform an additional calculation, based on the difference between the major diameter of the thread and the diameter of the thread mill. The formulas are on the SPEEDS & FEEDS chart for individual thread mill cutters.

A thread mill is similar to an endmill, but with the profile of a thread on the side. Modern CNC machines can helically interpolate all three axes to mill a thread profile into a workpiece. The operator can use the machine’s cutter compensation feature to very precisely control the thread’s major diameter. As the tool wears, offset adjustments will allow you to continue cutting good threads, as long as the form is still good. Thread mills typically produce more threaded holes per tool than taps, for this reason.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

These are right-hand cutting tools, meaning they must be programmed with an M03 Spindle On-Forward command on milling machines. These cutters can produce internal right-hand or left-hand threads. The difference is in the programming technique. The circular interpolation motion must be accompanied by a helical motion of the Z-axis equal to 1 pitch of the thread being cut. Positive motion in the Z-axis (moving Z upward) produces a right-hand thread, while negative motion (moving Z downward) produces a left-hand thread.

Custom Cutters - Peterborough - phone number, website & address - ON - Lawn Maintenance.

It also can be very expensive to remove a broken tap from a workpiece, especially if that workpiece is large. Broken thread mills are easily removed, and often, a new thread mill can be used to finish threading the hole, saving the part from having to be scrapped.

Find ratings, hours, directions, location information and more for Decatur Custom Tool - Peoria at 110 Harvey Ct. Add your review and photos for Decatur ...

Haas solid carbide thread mills allow threading of a range of hole sizes, in a wide range of materials, using the same thread mill.

Aug 15, 2019 — When you drill into block and concrete products, you will encounter a continuous mix of hard and soft pockets. You might be drilling a concrete ...

This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer. No other mandatory costs can be added to the delivery of a Haas CNC Product.

Work hardening, is the strengthening of a metal by plastic deformation. In the plastic region, the true stress increases continuously, meaning that when a metal ...

Thread mills cut with the side of the tool, so it is very important to use the most rigid toolholders. Typically, a collet chuck does not provide the necessary rigidity to cut high-quality threads. We recommend using a hydraulic chuck, milling chuck, or shrink-fit toolholder. An endmill holder may be used with caution, but might require modifications to speed and feed recommendations, to avoid chatter and excessive tool deflection.

Thread mills can also produce threads on the outside of a boss. Be aware that not all thread forms have the same specifications for internal and external versions. Some threads may require a unique thread mill for the internal and external versions.

Thread mills differ from taps, because they have a smaller diameter than the thread size produced. The thread mill cutter must be able to enter the drilled hole, and then interpolate the thread profile. Because offset adjustments can be used to compensate for tool wear – as long as the thread form is still good – thread mills typically produce more threaded holes per tool than taps.

Drilling hardened steel with regular masonry bits that have been sharpened. Shop Tricks and Tips.

... conventional. Antonyms for conventional. All found antonyms. digestible · fashionable · informal · original · unconventional · unconventionality · unorthodoxy.

0086-813-8127573

0086-813-8127573