Specialty Bits - Router Bits - Routing - essential router bits

Breaking tapscnc

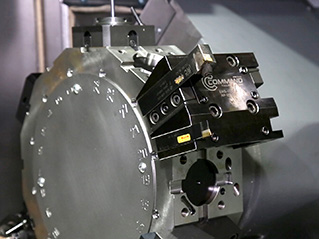

Feed rate has fewer effects on the process, but it is essential for the perfect finishing of the workpiece. To regulate the optimum value of the workpiece, machinists consider the factors given below:

This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer. No other mandatory costs can be added to the delivery of a Haas CNC Product.

Breaking tapsyoutube

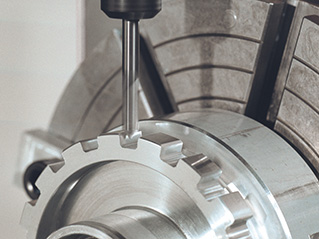

Optimum cutting speed is a necessity to improve the efficiency of CNC machining. As said before, CNC machining Services is a software-controlled process, and the cutting speed still depends on different factors. The following are a few important ones among them.

Breaking Tapszach

Cutting speed and feed rate maybe two different terms, which work simultaneously. Cutting speed is considered the speed of a tool that cuts the workpiece. In comparison, the feed rate is the distance traveled by the tool in one revolution of the spindle. Therefore, the feed rate is considered as the velocity at which the cutter is fed.

Zachary Tong

Cutting speed, also known as the surface speed, is the relative velocity between the cutting tool and the workpiece surface. There is an optimum cutting speed for each material and a set of machining conditions that differ between materials. This optimum feature of the cutting speed ensures the accuracy offered by the CNC machining process.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Feed rate is basically the distance at which the tool travels during its single spindle revolution. It is defined as the velocity at which the cutter is fed. It is represented in the units of distance per revolution turning.

Feed rate and cutting speed are only two factors to improve the efficiency of your CNC machine process. There are several other factors that may contribute to. However, you need not worry about these factors when you partner with a trusted and experienced player like Brogan & Patrick. The company takes pride in its technology investments and resource pool comprising CNC machining programmers and experienced machine operators. You can contact the experts today to discuss your machining needs.

CNC machining is a manufacturing process is the process where the metal piece is sheared until the desired shape is achieved. This process is computer-driven, but to get it right, the machine operator must be aware of the shearing capability and moving speed of the machine. In simple terms, they must be familiar with the feed rate and cutting speed of the CNC machine. This post gives you a brief understanding of the difference between feed rate and cutting speed in CNC machines.

0086-813-8127573

0086-813-8127573