Speed & Feed Charts - drill feeds and speeds

Carbide (Carb) drill bits are made from tungsten carbide, which is a dense and durable material that can resist high temperatures and wear. They are ideal for drilling through hard materials, including ceramics, glass, and masonry, as well as hard metals like stainless steel and cast iron.

Using the wrong bit can result in damage to the material, decreased efficiency, and even injury to the user. Therefore, it's essential to understand the various types of drill bits available and their unique features, including materials, coatings, point angles, and lengths.

When it comes to drilling, there are various types of drill bits designed for specific materials and applications. Here are some of the most common types:

PVD CoatingPrice

The drill point angle refers to the angle at which the cutting edge of the drill bit is ground. It is measured in degrees and can range from 90 to 150. A 118-degree angle is the most common, but other angles, such as 135 degrees and 90 degrees, may be more suitable for specific materials or applications.Common Drill Point Angles

Cobalt (HSCO) drill bits are made from high-speed steel with added cobalt, which enhances their strength and heat resistance. They can withstand higher temperatures and are less prone to dulling. Cobalt drill bits are ideal for drilling through hard metals, such as stainless steel, cast iron, and titanium.

Each type of drill bit has its own unique features, suitable applications, advantages, and disadvantages. Choosing the right type of drill bit is essential for achieving accurate and efficient results in drilling.

High-speed steel (HSS) is a type of tool steel that is highly resistant to heat and wear. It contains tungsten, molybdenum, chromium, and vanadium, which provide increased strength and durability. HSS drill bits are suitable for drilling into soft metals, such as aluminum and brass, as well as wood and plastic.

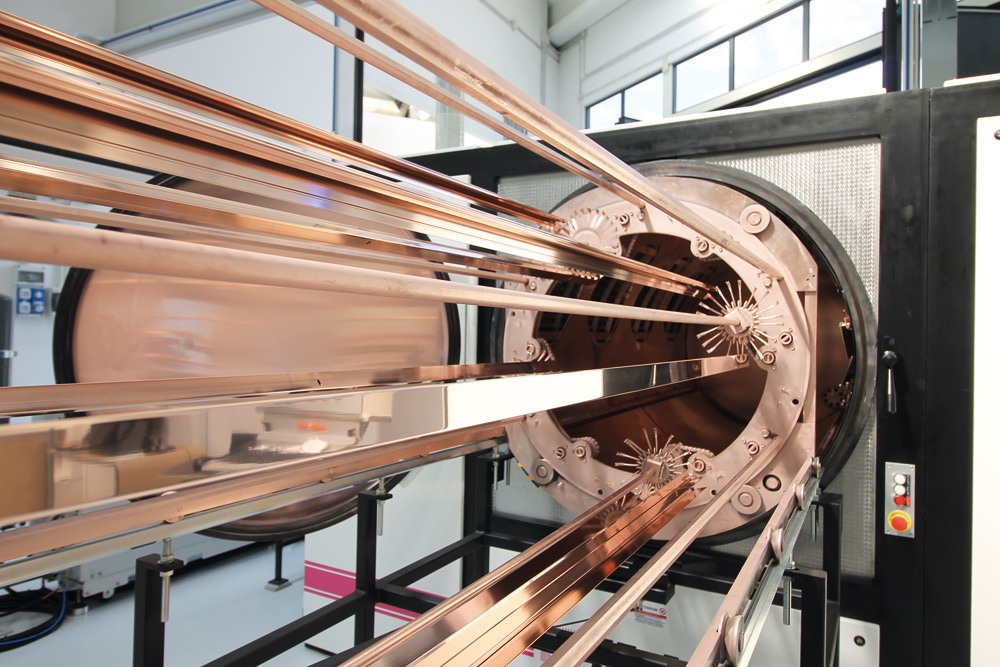

PVD coatingmachine

Functionality and aesthetics depend not only on design choices but also on the materials and processes used, now more and more often environmentally sustainable.

In the electron cannon deposition process, a hot filament generates a high electronic current that hits the material to be evaporated. This material is contained in a crucible, usually made of graphite, which in turn is contained in a copper heat sink. The electron beam thus dissipates its kinetic energy into the material, causing it to heat up and then evaporate.

Moreover, the versatility of PVD coatings also provides responses to two mega trends in the automotive sector: lightweight construction, which involves lightening all car components, and electric mobility, which requires a range of colours recalling electric power (greens and blues). As a thin film available in a broad selection of tints, PVD contributes to the lightness of cars, while meeting the growing demand of the industry for a wide range of finishes.

PVD coatingfull form

For example, the use of chromium trioxide in functional chrome plating with decorative purposes has been recently banned. This measure is part of a broader regulatory framework, called REACH, which is introducing increasingly stringent rules at the European level on the use of chemicals considered environmentally unfriendly and unsafe.

and it is therefore one of the cleanest application methods available. Any type of material, including heat-sensitive materials, can be coated thanks to the low process temperatures. In addition, it is possible to produce multi-layer systems by inserting several cathodes made in different materials into a vacuum coating system.

PVD coatingthickness

The development of PVD coatings has not only affected application processes, but also their related technologies, which currently include machines capable of integrating different types of operations, from sputtering to cathodic arc, in one solution.

In general, PVD is an atomic deposition technology, which creates the film atom by atom. During this process, the material is evaporated from a solid or liquid source and transported in vapour form through a vacuum or plasma environment to the substrate, where it condenses and adheres. The substrate may be metal, alloy, plastic, or wood.

A more sustainable alternative technology to chrome plating is PVD, which is already widely used in various sectors including cosmetic and food packaging, beverage, design and ornamental components, and funerary art, but also aluminium profiles for furniture, 3D printed components, fashion accessories, and car parts – all needing to achieve different shades and effects with a wide range of colours.

Although less common in the industry nowadays, thermal evaporation deserves special mention as one of the oldest thin film deposition techniques.

In the constantly evolving market of surface treatments, now looking for more and more environmentally sustainable solutions, PVD processes are increasingly playing a leading role. In this article, we explain in detail what PVD is, its most common industrial uses, its application technologies, and its advantages in terms of production and sustainability.

Pvd coating processstep by step

Therefore, whereas until recently the long process times, as well as the high quality requirements of some sectors such as the automotive industry, did not justify this investment, now the technological advancement of machines – which guarantee shorter cycle times, larger production volumes, and more competitive production costs – combined with the advantages guaranteed in terms of repeatable quality results and a more sustainable environmental footprint, is leading the industry to use PVD treatments more and more.

Sputtering, also known as cathodic vaporisation, is one of the most popular application methods in the industry. During this low-temperature operation, the ions of the process gas introduced into the vacuum chamber (usually argon) bombard the cathode (the material to be deposited), thus causing the ejection of atoms and molecular fragments.

The temperature of the arc is very high, thus enabling any material to be vaporised at an equally high speed. However, the high current intensity can make this technique difficult to manage and cause droplets, which in turn create defects in the coating.

Born in the Philadelphia area and raised in Houston by a family who was predominately employed in heavy manufacturing. Herb took a liking to factory processes and later safety compliance where he has spent the last 13 years facilitating best practices and teaching updated regulations. He is married with two children and a St Bernard named Jose. Herb is a self-described compliance geek. When he isn’t studying safety reports and regulatory interpretations he enjoys racquetball and watching his favorite football team, the Dallas Cowboys.

What isPVD coatingused for

During the arc evaporation process, evaporation is produced by an electrical discharge directed at the material to be deposited under low-voltage, high-current conditions, which causes the emission of highly ionised particles that adhere to the substrate.

This causes the particles ejected from the cathode to vaporise and settle on the substrate (anode), condensing and forming the coating film.

In the surface treatment industry, functionality and aesthetics play a major role in many sectors, such as that of packaging for cosmetics, where part of a product’s value precisely lies in its package.

One of the most important tools in any metalworker's arsenal is the drill bit. Drill bits are cylindrical cutting tools that are used to create holes in various materials such as metal, plastic, wood, ceramic tile, and concrete. But not all drill bits are made the same, and choosing the wrong one can lead to disastrous results.

What isPVD coatingon Stainless steel

Flutes are the grooves that run spirally along the length of a drill bit. They serve to remove chips and debris from the hole as the bit cuts into the material. They are also typically wider and deeper on larger diameter bits. Flute design can greatly affect the performance and efficiency of a drill bit.

To choose the best drill bits for metal and other materials, you should consider the design features that affect their performance. These are the three key design features of drill bits:

In this process, the material (solid or liquid) sublimates or evaporates in the presence of a current of considerable intensity, thus condensing on the substrate, on which the film is created.

The drill point length refers to the distance from the tip of the drill bit to the beginning of the flute. There are three types of drill point lengths: standard, jobber, and long.

Fill in the form to receive our newsletter and remain up-to-date with the latest and greatest of the surface treatments sector.

Some of these plants also integrate processes that are usually performed downstream, aimed at product customisation. This also ensures greater control over the technology and the ability to manufacture individual products – a feature that is increasingly in demand – while eliminating any outsourcing costs.

PVD machines generally guarantee high processing speeds, even for high production volumes, and a high level of process customisation. They can be installed off-line or in-line, thus constituting an actual plant.

Whether you're a seasoned metalworker or just starting, this guide will equip you with the knowledge you need to make informed decisions and achieve the best results.

PVD coatingmaterial

The material provided in this article is for general information purposes only. It is not intended to replace professional/legal advice or substitute government regulations, industry standards, or other requirements specific to any business/activity. While we made sure to provide accurate and reliable information, we make no representation that the details or sources are up-to-date, complete or remain available. Readers should consult with an industrial safety expert, qualified professional, or attorney for any specific concerns and questions.

Black oxide is a coating made by blackening the surface of the drill bit to enhance rust resistance and reduce friction. It is made from iron oxide and magnetite. They are best used for drilling soft metals such as aluminum, copper, brass, and mild steel.

When it comes to using drill bits, mistakes are not uncommon. These are some of the most common mistakes that you should avoid to ensure safety:

As is often the case in the world of surface treatments, the automotive industry is pioneering the use of this technology, perhaps still considered a niche technique, on a more widespread basis. This is happening thanks to the use of PVD to coat not only valuable parts for car interiors (a practice already well established), but also exterior components, such as alloy wheels, where physical vapour deposition replaces the application of a coloured base coat.

A bare metal finish with no coating. It is the most common type of drill bit. They are best used for drilling plastic, wood, and soft metals.

A gold-colored coating that provides heat resistance and hardness. It is made by depositing titanium nitride on the surface of the drill bit.They are best used for drilling hard materials such as stainless steel, cast iron, and titanium.

A gray-colored coating that is harder than TiN. It is made by depositing a layer of titanium carbonitride on the surface of the drill bit. They are best used for drilling abrasive materials like high-silicon aluminum, fiberglass, and carbon composites.

Pulsed laser deposition (PLD) involves the use of a laser beam that hits the material with high energy, causing it to evaporate and then adhere to the substrate. When the laser pulse is absorbed by the target, the energy is first converted into electronic excitation and then into thermal, chemical, and mechanical energy resulting in evaporation, ablation, plasma formation, and exfoliation.

PVD stands for Physical Vapour Deposition. It is a process that deposits a thin metallic film, about a few microns thick, to give the substrate protection against corrosion, scratches, and abrasion and resistance to UV rays and solvents. In addition to these protective and functional properties, it is also used to deposit decorative films of precious materials such as gold and silver.

In addition, any subsequent application of a high-strength organic topcoat guarantees the high durability of the PVD coating when subjected to atmospheric ageing and external mechanical stresses.

0086-813-8127573

0086-813-8127573