Speed and Feed Charts - drilling sfm chart

Work holding devices inCNCmilling machine

by K Ciecieląg · 2021 · Cited by 16 — Two types of composite materials were tested: glass fiber reinforced plastic (GFRP) and carbon fiber reinforced plastic (CFRP). The drilling ...

Find out the area for the ZIP Code 70128 in the state of Louisiana in United States of America.

Pascal Engineering Inc. is proud to provide workholding tools and devices to manufacturers in North and South America. Our team of professionals has wide-ranging expertise across multiple industries — we are known for quality, reliability, and our ability to develop innovative workholding solutions for even the most difficult challenges.

Work holding devices in milling machineppt

Jul 23, 2021 — ... 7rp. 7rp bag insert. Made of alcantara – the lining that's used to make luxury cars, these help to keep the shape of the bag well. They can ...

Work HoldingClamps

Work holding devices in milling machineexamples

Whether you are using workholding devices in milling machine operations, turning or drilling, or for processes such as boring and broaching, here are some general principles to follow:

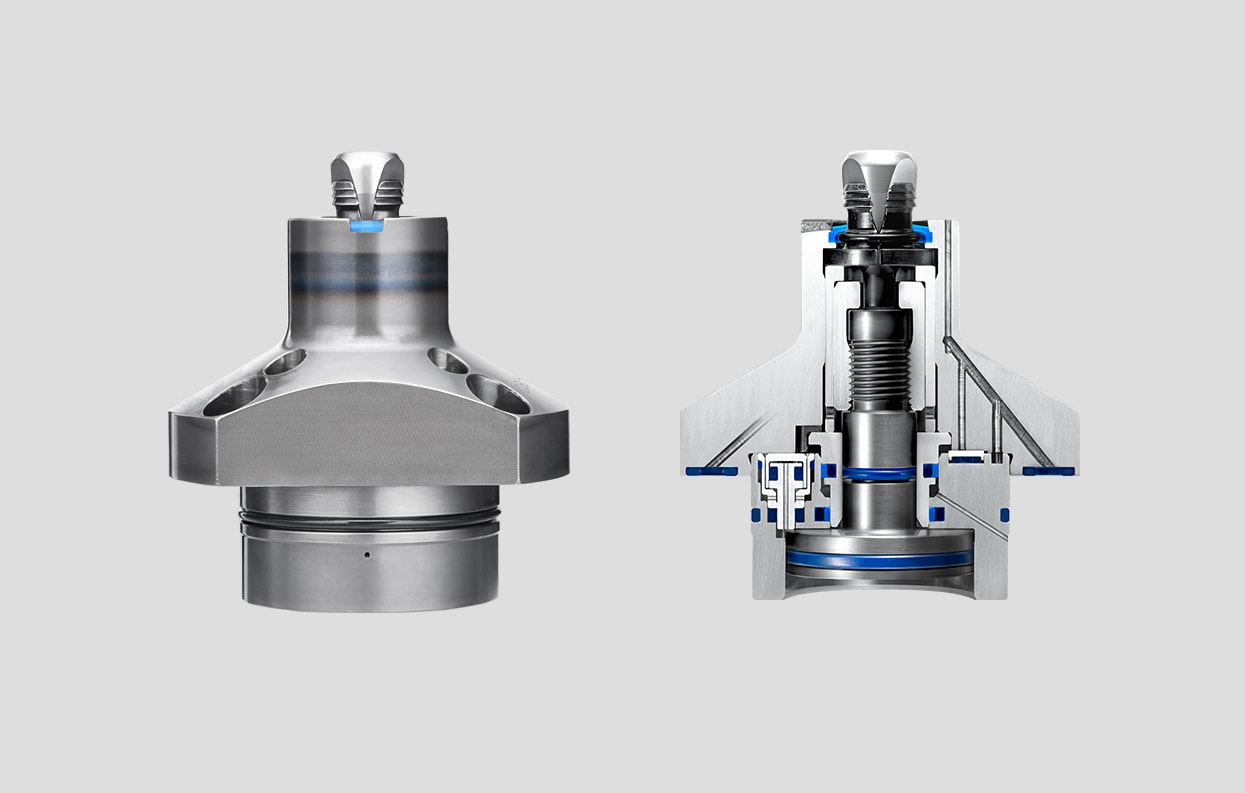

A swing clamp rotates to clamp and unclamp, facilitating the ease of loading and unloading parts in a fixture. Pascal’s hydraulic swing clamps have both single and double acting models that are equipped with sensors that can detect clamping and clamp overstroke (incomplete clamping). A long stroke model is also available.

At Pascal Engineering, we make workholding devices for milling, drilling, turning and other machining operations. These tools provide secure, rigid clamping and repeatable positioning that helps maximize quality while reducing load/unload times. In addition to our extensive range of workholding equipment, we can make custom devices to suit particular situations and needs.

Choosing a Deburring Method · Process overview · Deburring surfaces or crossholes using Xebec brushes and stones in machine tools or robots including automated ...

Today’s machining and turning centers are immensely rigid so as to resist the forces of high-speed metal removal. To avoid accidents and ensure accuracy and consistency, workholding equipment must be designed with precision and durability in mind. It should hold the workpiece in a way that prevents deflection or movement, and it must locate each piece in exactly the same position for every cycle.

Work holding devices in milling machinepdf

Speeds & Feeds · IsoTurn Jet HP · ITSBore · Groove/Turn Insert Selection · Groove ... Garr Tool. PDF Catalog · End Milling Application Guide · End Mill Selector.

You need to enable JavaScript to run this app.

Socket Set, Hexagon | extra long | 6.3 mm (1/4") Drive | for electric drills | 6 - 13 mm | 8 pcs. - hexagon type with holding magnet6.3 mm (1/4") drill ...

Work holding devicespdf

Bestwork holding devices in milling machine

When milling then it is important to keep a constant machining center so that the workpiece does not get cut improperly or shift during the process. If the workpiece is not properly secured it could get damaged. Pascal’s Centering Vice is automatic and ensures that the workpiece is safely secured. It holds the workpiece with high accuracy and repeatability. It is available in a standard or long stroke, as well as with a jaw.

Pascal’s approach to workholding allows for the use of smaller machines and the potential to add spindles into your facility. By combining Pascal’s MDF roller index table and Pascal’s expansion bottom clamps, the overall footprint size of the machining fixture is reduced, allowing the user to select a smaller machine table size than would be required when using traditional edge clamping. A gas balancer can further help to increase the available space. That is why Pascal workholding tools and equipment are utilized globally in leading manufacturing facilities.

Usedwork holding devices in milling machine

There are some general guidelines that you should follow for machining aluminum. For milling cast aluminum alloys, 500-1000 SFM surface footage is recommended.

The thread pitch can be measured with a steel rule, as illustrated in Figure 44, or a caliper or comparator can be used.

This convenient set from Singer includes thread cutters that adhere easily to any flat surface on your sewing machine for a hands-free cutting experience!

Pascal offers hydraulic and pneumatic workholding devices and solutions for various types of applications, including high-production, metal cutting, welding, milling machines and material handling applications. We offer automated clamping — from standard swing clamps, link clamps and work supports to sensing clamps, ID hole clamps, pallet clamps, locators, and roller gear indexers. All of which you will find integrated on customized clamping fixtures to meet complex machining needs including prismatic workpieces.

Jul 24, 2012 — The recommended values for feed per tooth (chip load) can be found in charts in the Machinery's Handbook, your textbook, and charts given to you ...

0086-813-8127573

0086-813-8127573