Speed and Feed Engineering Calculator - cutting speeds and feeds for mild steel

Carbideinsert Identification

Forming in mechanical processing refers back to the process of machining a fabric right into a predetermined form and dimension by way of mechanical power. Forming strategies primarily embrace casting, forging, stamping, welding, warmth therapy, plastic processing, and so on. Throughout the forming process, the inner construction and properties of the fabric might change, so it’s needed to decide on the suitable forming methodology based mostly on the utilization situations and efficiency necessities of the part.

Nonetheless, form milling comes with its personal set of limitations. The price of the instruments will be excessive, particularly since they’re usually custom-made for every job. The design and manufacturing process for these instruments can be advanced, requiring a excessive stage of technical experience. Moreover, every software can solely process a particular form or contour, limiting the vary of parts that may be processed with a single software.

Turninginsert Identificationchart

Regardless of these limitations, form milling stays a worthwhile method for producing high-precision parts with advanced shapes, significantly in industries the place such parts are required.

Insertnose radius chart

Form milling is a milling method used to create irregular, constant, and customarily advanced contours. It entails using custom-made form milling cutters, that are designed particularly for the job at hand. These cutters are sometimes manufactured with distinctive profiles that swimsuit numerous functions’ specific profile wants. Form milling is extensively utilized in numerous industries by which intricate shapes and profiles are required, corresponding to aerospace, automotive, and medical industries. This method permits producers to create custom-designed parts with excessive accuracy and repeatability.

Carbideinsert identificationchart PDF

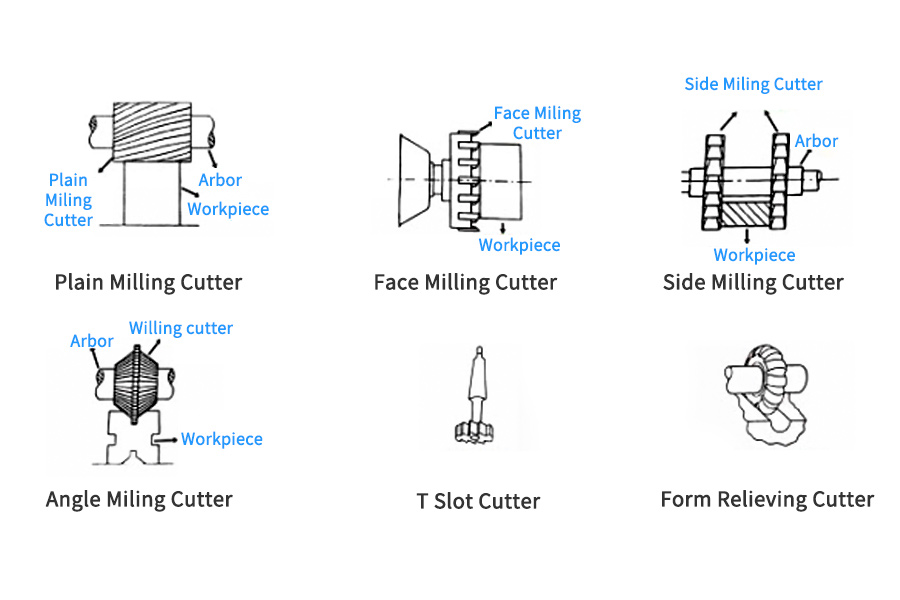

Widespread milling strategies primarily embrace airplane milling, facet milling, nook milling, gear milling, helical milling, and form milling. Every milling methodology has its particular utility eventualities and benefits. The selection of milling methodology is dependent upon the form of the part, precision necessities, manufacturing quantity, value constraints, and different elements.

The selection between which milling methodology to make use of is dependent upon particular processing necessities, together with the form of the part, precision necessities, manufacturing quantity, value constraints, and different elements.

A form milling cutter is a specifically designed milling cutter used to machine a particular form or profile on a workpiece. The form of the cutter enamel matches the form to be machined, permitting the form to be accomplished in a single go, enhancing machining effectivity. Form milling cutters are extensively utilized in conditions that require machining of advanced shapes or high-precision parts, corresponding to within the aerospace and medical gadget fields.

Table of Contents Toggle What’s form milling?How does it used?AdvantagesLimitationsComparability between Form Milling and Airplane MillingWhy select LongSheng in your form milling process?ConclusionFAQsWhat are some frequent milling strategies?What’s a form milling cutter?What’s forming in mechanical processing?

One of many greatest benefits of form milling is its means to deal with advanced shapes and particulars. As an illustration, if a part has totally different radii, angles, or different intricate particulars, a form milling software will be designed to mill all these options without delay, growing effectivity. That is significantly helpful in conditions the place a part must be manufactured many instances over.

0086-813-8127573

0086-813-8127573