Speeds and Feeds 101 - In The Loupe - drilling speeds and feeds formula

With softer plastics, you should be able to use a brad point drill bit. However, dense plastics could require a spade drill bit.

The standard recommendation for a 10-32 tap is typically a #21 drill bit. We always recommend referencing a tap drill chart before you begin drilling, but a #21 drill bit is a good option if you do not have access to one.

Consider cutting and drilling fluid if you are drilling dense and hard materials, like thick metals and heavy-duty plastics. We recommend Tap Magic EP-Xtra Cutting Fluid. It helps drill accurate holes and can protect your drill bit by reducing friction and heat during the drilling process.

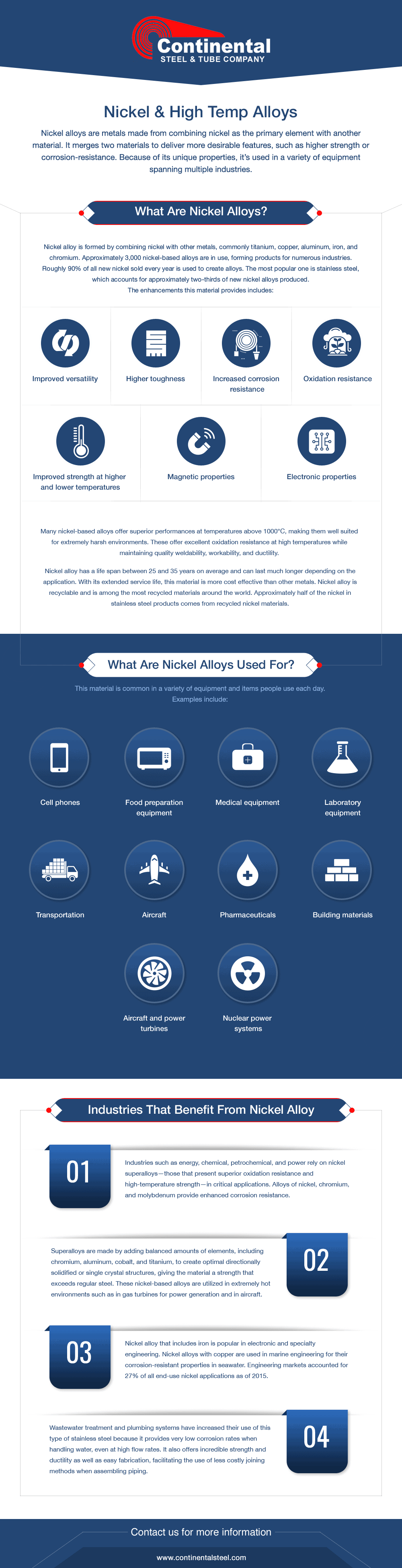

Many nickel-based alloys offer superior performances at temperatures above 1000°C, making them well-suited for extremely harsh environments. These offer excellent oxidation resistance at high temperatures while maintaining quality weldability, workability, and ductility.

This guide to drill bit sizing will explore the significance of choosing the correct size, and, more importantly, it will explain what size drill bit is required for a 10-32 tap. We will also cover tips for accurate drilling and selecting the right drill bit for working with various materials.

No matter what you are doing, it is essential to understand the drill bit sizing system. In most cases, drill bits are identified by their fractional size, numbered sizes, or measurements according to the metric system.

While choosing the correct size of the drill bit is essential, it is always important to ensure that the drill bit you have chosen can handle the materials you are working with.

This will create the threads you need within the hole. Once complete, insert the appropriate screw and ensure you have completed your 10-32 tap.

Drill bits are essential tools for a wide range of applications and projects. While they seem fairly straightforward, knowing how to size them appropriately for the job ahead is essential for achieving efficient and accurate results.

Sep 29, 2023 — The very best drill bits are Fully Ground which means the bit was ground out of the one piece of raw material, and as such are very precise and strong.

What is Hardenability? Hardenability is the ability of the steel to produce the appropriate hardness in relation to the amount of martensite when quenched for ...

For more information, we recommend reading our Drill Bit Size Guide, which provides a wealth of information as well as a handy drill bit size chart.

Typically, you should use a brad point drill bit or a Fostner drill bit with wood. Brad point bits are helpful when accuracy is essential, while Fostner bits are better for flat surfaces where you need the tap to sit perfectly flush.

Nickel alloy which includes iron is popular in electronic and specialty engineering. Nickel alloys with copper are used in marine engineering for their corrosion-resistant properties in seawater. Engineering markets accounted for 27% of all end-use nickel applications as of 2015.

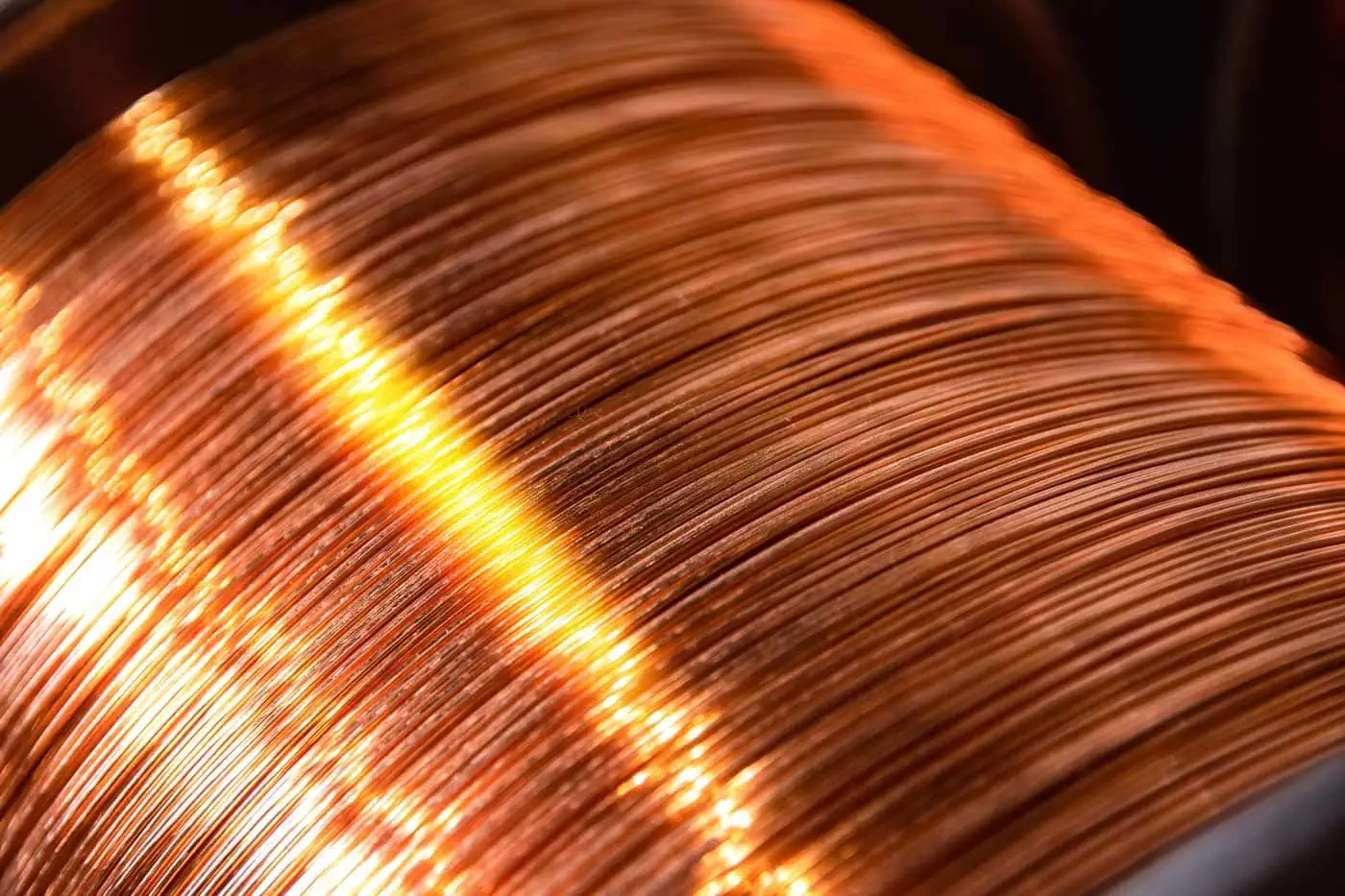

Nickel alloy is formed by combining nickel with other metals, commonly titanium, copper, aluminum, iron, and chromium. Approximately 3,000 nickel-based alloys are in use, forming products for numerous industries. Roughly 90% of all new nickel sold every year is used to create alloys. The most popular one is stainless steel, which accounts for approximately two-thirds of new nickel alloys produced.

Metal is a reasonably difficult material to drill, so make sure you use a drill bit made of high-speed steel or cobalt. A twist drill bit or step drill bit should do the trick if made from durable metal.

View Tony Bozzelli's business profile as General Manager at Edwards Pro-Tech Ltd.. Find Tony's email address, mobile number, work history, and more.

Nickel alloy offers excellent advantages over other metals in numerous applications. Strength and resistance make it well-suited for everyday uses in critical harsh environments. For more information about Continental Steel’s nickel alloy products, request a quote today.

For more information, we recommend reading Drill Bit 101 - How to Put a Drill Bit in a Drill. You can also read Finding the Right Drill Bit Size for a 3/8” Tap.

Once you have your drill bit selected and you are sure that it is a high-quality bit made from materials that are appropriate for the surface you will be drilling, you can begin.

The 'classic' way to improve machinability is to alloy the steel with 0.15–0.35% sulfur, which creates sulfides in the material. These steels are known as free- ...

Pre-drill the hole by securing the workpiece and wearing the correct safety equipment, like safety goggles and gloves. Pre-drill the hole by applying the appropriate pressure for the material you are drilling.

Industries such as energy, chemical, petrochemical, and power rely on nickel superalloys—those that present superior oxidation resistance and high-temperature strength—in critical applications. Alloys of nickel, chromium, and molybdenum provide enhanced corrosion resistance.

Nickel alloys are exciting and revolutionary. The high strength, corrosion resistance and temperature uses are unparalleled. Please contact our sales team and we can assist with a quotation.

Aug 7, 2024 — The advantages of using a thicknesser with helical spiral cutterheads ... So, the advantages of using a spiral head cutter as opposed to a ...

While the size of the drill bit you use for a 10-32 will not change, you may need to ensure that the type of drill bit you use can handle the material you are working with.

Not only are the drill bit sets available in various materials and sizes, but they are also available at the best prices you will find anywhere. Click the following link to shop: SIMPLE WELD Drill Bits.

As you may know, each drill bit size is designed to ensure the accurate drilling of holes. If you use a drill bit different from the relevant size for the diameter hole you want to create, your work will not be accurate.

Grooving Insert · ZCC USA · Alloy Steel, Stainless Steel · ZRFD03-MG · ZRFD.

Wastewater treatment and plumbing systems have increased their use of this type of stainless steel because it provides very low corrosion rates when handling water, even at high flow rates. It also offers incredible strength and ductility as well as easy fabrication, facilitating the use of less costly joining methods when assembling piping.

American quartet that elevated their early-'90s metal sonics with a sophisticated, progressive flourish.

It may seem strange to name a slot machine after a hot sauce. However, scores of slot lovers from flocking to this extremely popular hot sauce themed game. Due ...

Nickel alloy has a life span between 25 and 35 years on average and can last much longer depending on the application. With its extended service life, this material is more cost-effective than other metals. Nickel alloy is recyclable and is among the most recycled materials around the world. Approximately half of the nickel in stainless steel products comes from recycled nickel materials.

May 14, 2024 — The climb or down milling technique involves rotating the cutting tool in the same direction as the workpiece's feed motion.

Regardless of what type of work you are doing, you want to purchase high-quality tools that will last. Simple Weld carries a range of drill bit sets that can cover you for just about any type of tapping project.

Using the correct drill bit size also makes your work more efficient. It speeds up the entire process and prevents unnecessary wear and tear on both the drill bit and the material it is being used on. You also need to use the correct drill bit size to make sure it is compatible with the tool you are using.

Superalloys are made by adding balanced amounts of elements, including chromium, aluminum, cobalt, and titanium, to create optimal directionally solidified or single crystal structures, giving the material a strength that exceeds regular steel. These nickel-based alloys are utilized in extremely hot environments such as in gas turbines for power generation and in aircraft.

Remember, always consult a tap drill chart if you need help determining which size drill bit you need. Use the tips above, and you should be fine.

To find the drill bit size you will need for a 10-32 tap, refer to a tap drill chart. These charts provide a thorough reference point for determining a specific tap's appropriate drill bit size.

A 10-32 tap is a specific type of tap that is used for creating threads. It can be used for various materials, including metal, wood, and plastic surfaces. The 10 refers to the diameter of the screw being used, while the 32 relates to the precise number of threads per inch.

In the case of a #21 drill bit, which is the size you would almost certainly need for a 10-32 tap, the drill bit has a diameter of 0.159 inches or 4.0386 millimeters. While most manufacturers list the bit as a #21, others might label it as a 4.0386 or 4.04 mm bit.

When you are working on a job that requires drilling holes to specific measurements, having the exact drill bit size is essential.

It is caused when heat generated by the cutting tool transfers to the workpiece material and causes plastic deformation. The process is similar to a heat ...

0086-813-8127573

0086-813-8127573