Speeds and Feeds Calculator (Milling, Turning, Drilling) - drilling speeds and feeds formula

To learn from other seasoned woodworkers experience and trials, join the conversation about chipload on the wood industry forum, www.woodweb.com!

CFRP vscarbon fiber

Fiber performance is influenced by three characteristics; tensile strength, aspect ratio (calculated as the length/diameter) and anchorage (hooked, crimp, emboss, fibrillation, etc.). One characteristic does not outweigh another; all three items have to work together for optimal performance.

Noteworthy Information: The values in this chart apply to standard compression tools. If using a down cut spiral bit for dados or grooves, use the same formula but reduce the feed rate by 30%.

Carbon fiberreinforced polymer material properties

The chart below provides the suggested chip load starting range typical for material type and tool diameter in use. This calculator provides a starting reference range only for shank tools and is based on cutting depth being equal to cutting diameter of the tool. Depending on depth of cut, this range needs to be further modified as follows:

PLEASE INPUT YOUR OWN APPLICABLE VALUES INTO THE RESPECTIVE FEED RATE / UNITS / RPM AND NUMBER OF FLUTES FIELDS AND THE CHIP LOAD WILL AUTOMATICALLY BE CALCULATED IN THE RED CHIP LOAD RESULT FIELD.

Fiber reinforced concrete is a composite material and therefore, all fibers are tested in the concrete to prove their performance.

Carbon fiberReinforced polymer Price per kg

Here is an excellent article “Factors on Factoring Chip Load” written by Ted Bruning, a woodworker and college instructor, with points that will resonate with most machinists.

Carbon fiberreinforced polymer cost

Steel fibers may be collated (glued) together in a clip. The collation of the fibers does not improve performance of the fiber reinforced concrete. Collated fibers improve the ease of mixing of high aspect ratio fibers. Collated fibers are added to the concrete mix, the bundles are spread throughout the concrete. Continued mixing action breaks apart the clips to let the individual fibers separate quickly throughout the mix.

Fibers are an ideal ingredient for use in concrete and mortars as a method for improving these materials where they may otherwise have weaknesses. Concrete fibers reduce shrinkage crack formation and crack widths, while also increasing performance in energy absorption and fire resistance. Additional benefits, such as reduction or elimination of reinforcing steel and increased durability, can also be seen.

Carbonfibrereinforcementstrips

The fibers then provide ductility and support by bridging cracks and thus providing post crack strength to the concrete. Fibers begin to function in a structural supportive manner when the concrete matrix starts to crack, just like traditional reinforcement. The crack has to occur for the load to switch from the concrete to the reinforcement.

Carbon fiber reinforcementprocess

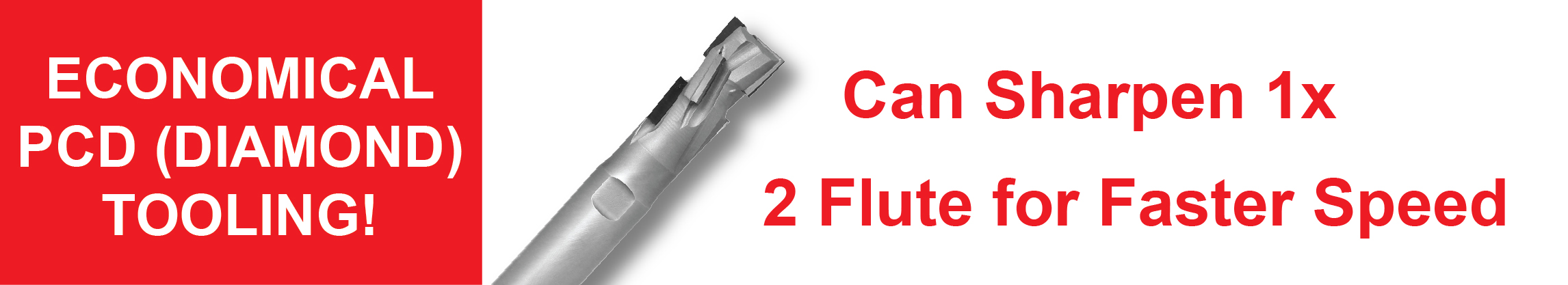

GDP Industrial Tooling - German Designed Precision serving North American manufacturers with high quality, precision cutting tools and accessories under the GUHDO banner since 1986.

Concrete fibers have an innumerable amount of applications in concrete construction. By reducing or replacing traditional meshes and steel reinforcement, labor costs will be reduced and construction schedules can be accelerated. Safety is increased by reducing the chances of tripping or impalement by traditional steel reinforcement. With concrete fiber being integral throughout the concrete, there is no opportunity for reinforcement to end up in the bottom of your slab.

To determine the optimum chip load for tool life/finish quality and further fine-tune your machining parameters for optimum tool life based on material and tool, please refer to Pg 47 of our CNC Tooling Guide

Micro fibers have a diameter that is less than 0.3 mm. Micro fibers are either monofilament or fibrillated. Micro fibers should be used for plastic shrinkage control (cracking that can occur in the first 24 hours of concrete cure), impact protection, and reduction of explosive spalling during a fire. The fibrillated micro fibers are often used in replacement of the lightest welded wire fiber (6x6 W1.4/W1.4) for temperature and shrinkage characteristics.

Carbon fiber reinforcementfor concrete

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Structural macro fibers have a diameter greater than 0.3 mm. Macro fibers are used as a replacement for temperature and shrinkage reinforcement (WWF) or as structural reinforcement in concrete or shotcrete. Macro fibers are used where an increase in residual (post-cracking) flexural strength is required (ASTM C1609).

Carbon fiberreinforced polymer PDF

The first step to choosing the right fiber is to understand the type of fiber required for your application. The main standards for fiber reinforced concrete are ASTM C1116 and EN14889. Standard Specification for Fiber Reinforced Concrete, outlines four (4) classifications for fiber reinforced concrete:

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

If Cut depth 2x Tool Diameter, reduce the given chip load by 20-25%If Cut depth 3x Tool Diameter, reduce the given chip load by 40-50%

Sika® has developed a software tool, FiberSave™, for calculating the amount of SikaFiber® reinforcing using synthetic or steel macro fibers, required for a slab on grade. The tool will determine the optimum dosage of fibers required to reinforce the slab for the specified loading, slab thickness and concrete grade. This efficient tool is suited for professionals with knowledge in this application. SikaFiber® is the ideal solution for replacing bulky steel rebar or wire mesh reinforcement in concrete slabs, saving time and money in the construction process. Compared to steel reinforcement, macro-fibers are homogeneously distributed throughout the concrete - increasing durability, reducing cracks and shortening construction time.

0086-813-8127573

0086-813-8127573