Square End Mills - square end mills

Performance titanium groupowner

TitaniumInternational

Application First choice and outstanding performance for hardned steels above 55 HRC. Excellent grade for finishing operations in cast iron and steels. Extremely hard and ultra fine grained grade.

SMG K (Cast Iron) is divided in 7 sub-groups, to capture specific material characteristics and reduce the complexity of every specific material.

Titaniumfor sale

Coolant Dry + WetApplication PVD-coated version of H15. Hard and wear resistant grade for rough milling in aluminum and non-ferrous alloys. Optimization in case of too high abrasive wear when machining higher Si content based non-ferrous metals. Excellent grade, in combination with protected cutting edges, for high speed machining in hardened steel. Ideal for finishing application of cast iron and steel.

Application Your first choice for maximizing manufacturing output when dealing with wide variations in stability, versatility and workpiece material requirements. A versatile and reliable grade ideal for milling in steel, stainless steel and superalloys under both stable and usntable conditions. It is a tougher alternative to MP2501 to overcome issues like edge chipping. Can be applied under dry and wet machining conditions.

Titaniumperiod

Application Grade with a tough CVD coating structure which is beneficial for rough milling of superalloy materials, tool steels as well as high alloyed stainless steels.

TitaniumIndustries

Application Your first choice for maximizing manufacturing output when dealing with wide variations in productivity, cutting data and workpiece material requirements. Alternative in stainless steel applications with stable conditions and higher cutting speeds.

Titanium Groupnumber

Application Peak performance in roughing of grey cast iron at higher cutting speeds. CVD-coated high temperate and wear resistant grade. Alternative grade for roughing ductile cast iron under dry and stable cutting conditions at high cutting speeds.

TitaniumMetals

Application First choice in all cast iron materials especially at smaller diameters. Peak performance in cast iron dry and with coolant as well in higher tensile steels and hardened steels. Grade offers an improved edge integrity and the TiSiN PVD-coating provides a high wear resistance against abrasive wear. Excellent for milling with and without coolant.

Application PVD-coated fine grained grade for fine to medium rough milling as well as finishing purposes. Ideal grade for steel with lower tensile stress and peak performance in hardened steels. PVD-coated version of H25. Optimization in case of too high abrasive wear when machining higher Si content based non-ferrous metals.

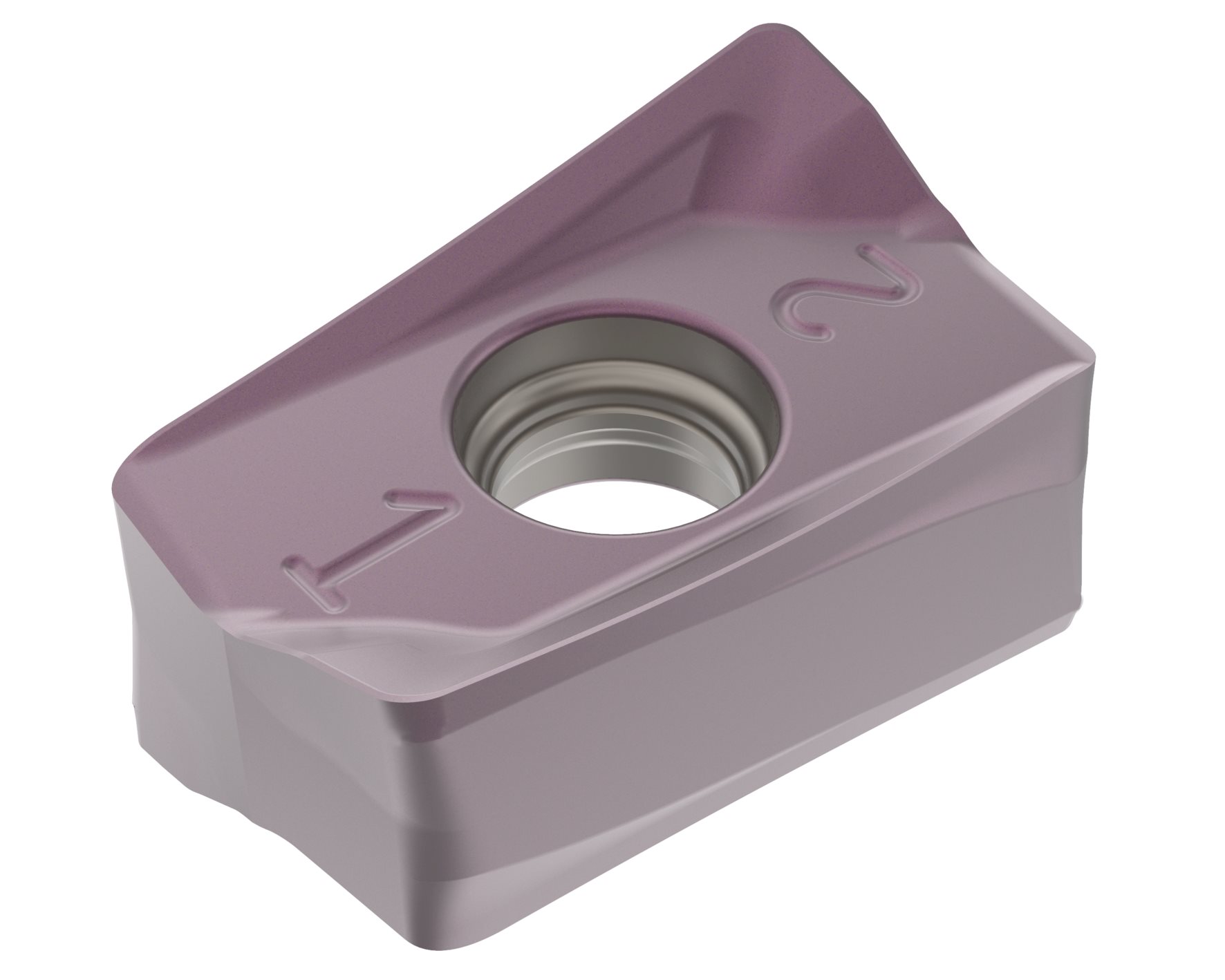

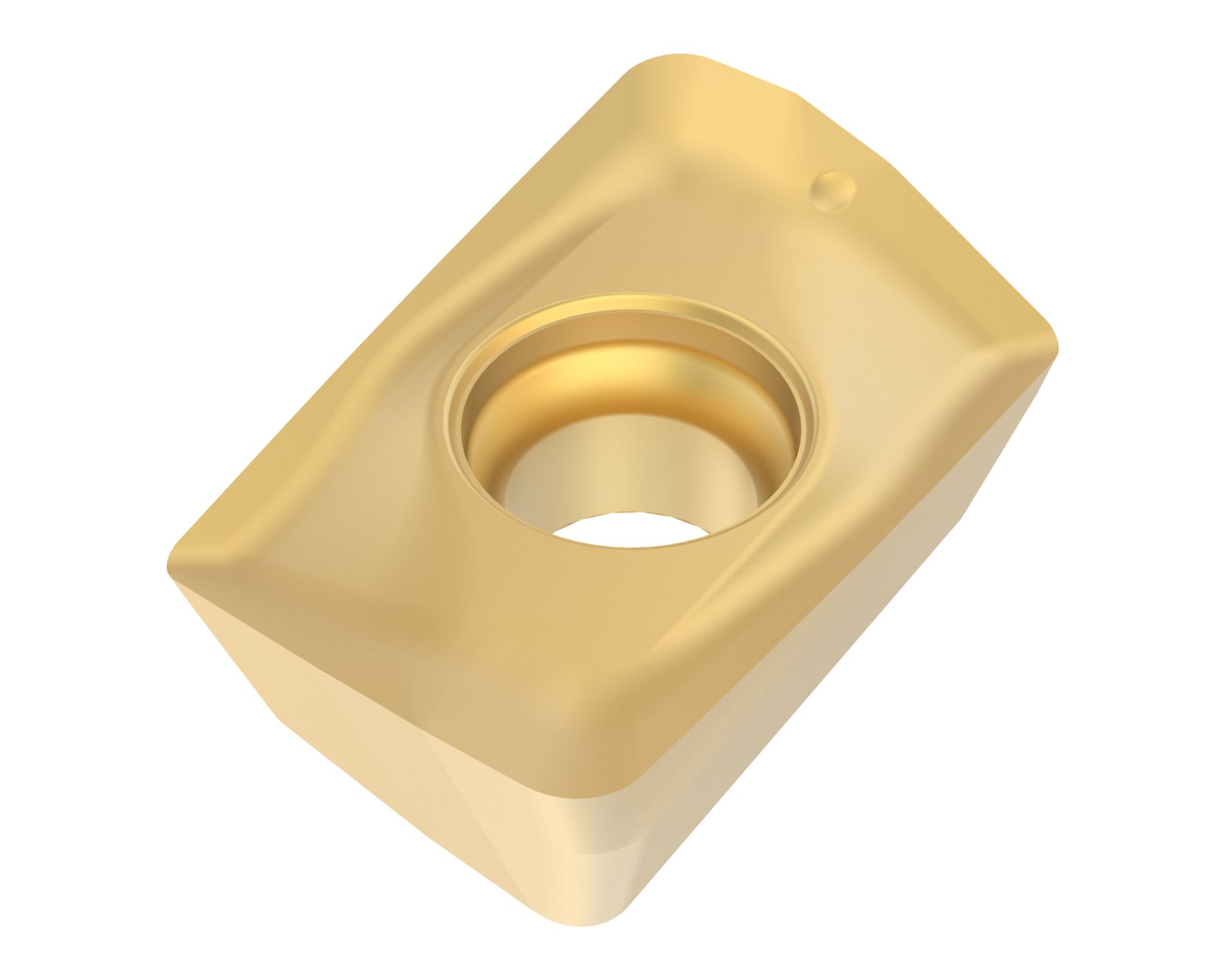

Material grouping and Grades references for Cast IronSMG K (Cast Iron) is divided in 7 sub-groups, to capture specific material characteristics and reduce the complexity of every specific material.Based on grade portfolio, first and second choices are provided for each sub-groups. This is a starting grade recommendation which can be optimized depending on the application, based on below mentioned grade mapping. SMG DescriptionReferenceFirst ChoiceSecond ChoiceK1Grey cast ironEN-GJL-250CVD: MK1500PVD: MK2050CVD: MP1501PVD: MP3000K2Compacted graphite irons (CGI)EN-GJV-400CVD: MK1500PVD: MK2050CVD: MP1501PVD: MP3000K3Malleable cast iron (MCI)EN-GJMB-550-4CVD: MP1501PVD: MK2050CVD: MK1500PVD: MP3000K4Nodular cast irons (SGI)EN-GJS-500-7CVD: MP1501PVD: MK2050CVD: MK1500PVD: MP3000K5Austempered ductile irons (ADI)EN-GJS-1000-5CVD: MP1501PVD: MK2050CVD: MP2501PVD: MP3000K6Austenitic lamellar cast ironsEN-GJLA-XNiCuCr15-6-2CVD: MP2501PVD: MK2050CVD: MP1501PVD: MP3000K7Austenitic nodular cast ironsEN-GJSA-XNiMn23-4CVD: MP2501PVD: MK2050CVD: MP1501PVD: MP3000 Discover this material in details Mapping of Cast Iron milling grades Discover our Product Range Get to know our grades for Cast Iron milling MK1500Carbide P20 / coarse grainCoating medium thick CVD Ti(C,N) + Al2O3Color BlackSMG K1 – K5Coolant DryApplication Peak performance in roughing of grey cast iron at higher cutting speeds. CVD-coated high temperate and wear resistant grade. Alternative grade for roughing ductile cast iron under dry and stable cutting conditions at high cutting speeds.Tougher Grade Option -Harder Grade Option MP1501 MP1501Carbide P20 / coarse grainedCoating medium thick CVD Ti(C,N) + Al2O3Color Silver (Used Edge Detection Layer)SMG P4 – P8 / K1 – K7 / H8 - H21Coolant DryApplication You first choice for high performance and productivity under more stable conditions in steel applications. Optimization of MP2501 due to higher wear resistance to also cover higher tensile stress or hardened steels. Excellent grade for wet machining of grey cast iron and especially peak performance in nodular cast iron to support MK2050 or MK1500.Tougher Grade Option MP2501Harder Grade Option MK1500 MP2501Carbide P30 / medium grainCoating medium thick CVD Ti(C,N) + Al2O3Color Silver (Used Edge Detection Layer)SMG P2 – P8 / M1 – M3 / K1 – K8Coolant Dry + WetApplication Your first choice for maximizing manufacturing output when dealing with wide variations in productivity, cutting data and workpiece material requirements. Alternative in stainless steel applications with stable conditions and higher cutting speeds.Tougher Grade Option MP3501Harder Grade Option MP1501 MS2500Carbide P30 / medium grainedCoating medium thick CVD Ti(C,N) + Al2O3Color BlackSMG P4 – P12 / M1 – M5 / S1 – S13Coolant Dry + WetApplication Grade with a tough CVD coating structure which is beneficial for rough milling of superalloy materials, tool steels as well as high alloyed stainless steels.Tougher Grade Option MP3501Harder Grade Option MP2501 MP3501Carbide P35 / medium grainedCoating medium CVD Ti(C,N) + Al2O3Color Silver (Used Edge Detection Layer)SMG P1 – P12 / M1 – M5 / K4 - K8Coolant Dry + WetApplication Your first choice for maximizing manufacturing output when dealing with wide variations in stability, versatility and workpiece material requirements. A versatile and reliable grade ideal for milling in steel, stainless steel and superalloys under both stable and usntable conditions. It is a tougher alternative to MP2501 to overcome issues like edge chipping. Can be applied under dry and wet machining conditions. Tougher Grade Option MM4500Harder Grade Option MP2501 F15MCarbide P10 / ultra fine grainCoating PVD TiAlN/TiNColor GoldSMG N1 – N11 / K1 – K8 / H8 – H21Coolant Dry + WetApplication PVD-coated version of H15. Hard and wear resistant grade for rough milling in aluminum and non-ferrous alloys. Optimization in case of too high abrasive wear when machining higher Si content based non-ferrous metals. Excellent grade, in combination with protected cutting edges, for high speed machining in hardened steel. Ideal for finishing application of cast iron and steel. Tougher Grade Option MP3000 / F30M / MK2050Harder Grade Option MH1000 F40MCarbide P30 / ultra fine grainCoating PVD TiAlN/TiNColor GoldSMG P1 – P12 / M1 – M3 / S1 - S13 / K1 – K7 / N1 - N11Coolant Dry + WetApplication Most universal grade that can handle all materials. High performance in low to medium alloyed steels, stainless steels as well as titanium based materials. PVD-coated grade for fine to medium rough milling. First choice for milling with small feeds and/or low cutting speeds. Excellent for milling when there is a risk of vibrations and when coolant is used.Tougher Grade Option MP2050Harder Grade Option MS2050 MK2050Carbide P20 / medium grainCoating PVD TiSiNColor PurplishSMG P3 – P6 / K1 – K4 / H11 – H21Coolant Dry + WetApplication First choice in all cast iron materials especially at smaller diameters. Peak performance in cast iron dry and with coolant as well in higher tensile steels and hardened steels. Grade offers an improved edge integrity and the TiSiN PVD-coating provides a high wear resistance against abrasive wear. Excellent for milling with and without coolant.Tougher Grade Option MP3000 / MS2050Harder Grade Option F15M / MH1000 MP3000Carbide P20 / ultra fine grainCoating PVD TiAlN/TiNColor GoldSMG P1 – P8 / M1 – M3 / H11 – H21Coolant Dry + WetApplication PVD-coated fine grained grade for fine to medium rough milling as well as finishing purposes. Ideal grade for steel with lower tensile stress and peak performance in hardened steels. PVD-coated version of H25. Optimization in case of too high abrasive wear when machining higher Si content based non-ferrous metals.Tougher Grade Option MS2050 / F40MHarder Grade Option MK2050 MH1000Carbide P05 / ultra fine grainCoating PVD TiAlN/TiNColor GoldSMG P1 – P5 / K1 – K8 / H11 – H21Coolant Dry + WetApplication First choice and outstanding performance for hardned steels above 55 HRC. Excellent grade for finishing operations in cast iron and steels. Extremely hard and ultra fine grained grade.Tougher Grade Option -Harder Grade Option F15M / MP3000 Inline Content - SurveyCurrent code - 5fce8e61489f3034e74adc64

Application Most universal grade that can handle all materials. High performance in low to medium alloyed steels, stainless steels as well as titanium based materials. PVD-coated grade for fine to medium rough milling. First choice for milling with small feeds and/or low cutting speeds. Excellent for milling when there is a risk of vibrations and when coolant is used.

Based on grade portfolio, first and second choices are provided for each sub-groups. This is a starting grade recommendation which can be optimized depending on the application, based on below mentioned grade mapping.

Application You first choice for high performance and productivity under more stable conditions in steel applications. Optimization of MP2501 due to higher wear resistance to also cover higher tensile stress or hardened steels. Excellent grade for wet machining of grey cast iron and especially peak performance in nodular cast iron to support MK2050 or MK1500.

0086-813-8127573

0086-813-8127573