stainless feed and speed help - stainless steel speeds and feeds

CareerBuilder has been a trusted source for hiring since 1995. Reach 80+ million unique, diverse U.S. job seekers annually by posting your jobs through their talent acquisition channels. Through CareerBuilder, you can engage candidates and drive them into your sourcing pipeline. We recommend using CareerBuilder for hiring when you have the internal resources and processes to review, screen, and reply to all applicants.

This position requires a high school diploma or equivalent. Community colleges and technical schools offer programs to train in this field.

Entry level Machinistjobs

... Turning-Axial-Right Hand-Style SCKCR. 10-3211 | Turning Tools. Made from ... insert; Made from precision ground heat treated steel; Insert not included. PRODUCT ...

Current employees are every organization’s greatest asset. Encourage your internal team to promote job openings to their network by offering cash and other incentives.

Entry Level Machinistsalary

Re-running a full-depth V cut can clean things up, or a gentle touch w/ a brass or nylon bristle brush may work for some instances, or there’s always a sharp knife/chisel/gouge or sandpaper.

The CNC Machinist performs detailed machine setups, G & M code (CNC) programming, machine process improvement and troubleshooting, and produces machined parts using a variety of CNC machines.

As the CNC Machinist for ABC Company, you will have the opportunity to use a variety of precision measuring instruments, inspect in process or finished parts and feature characteristics as well as manufacturing methods to blueprint specifications. This is a chance for you to develop a career within a global business and to help us improve our processes.

Entry level CNCjobs

Answering these questions will help determine the best course of action for your current hiring need. Fortunately, various great options exist for every scenario, no matter how unique. We recommend the following options when hiring a CNC machinist:

We match top professionals with great employers across the country. From filling urgent job openings to developing long-term hiring strategies, our team is here to help. Review our staffing solutions, browse our award-winning Staffing Corner blog, or call today. We look forward to connecting with you soon.

CNC machinist salaries vary by experience, industry, organization size, and geography. To explore salary ranges by local market, please visit our sister site zengig.com.

It looks like you’re depth limiting a V carving — the normal toolpath is down the centerline — try an Advanced V carving instead which will cut along the perimeter and yield a better appearance.

A great lineup of generators, pressure washers, power tools, hand tools, air compressors, welders, material handling equipment and more from the top national ...

When recruiting a CNC machinist, having the right job description can make a big difference. Here are some real-world job descriptions you can use as templates for your next opening.

If you wish to cut text which is so large/wide as to not allow cutting w/ a single pass of a #301 or #302 you can either use a larger tool and cut deeper, or an Advanced V-carving tool path (if desired, w/ the pocket clearing option).

I’ll definitely try running the toolpath twice to see if that cleans things up, I was just hesitant to do that due to the estimated time. I noticed that much of the milling time is spent with the machine taking very small cuts and with the router constantly raising and lowering which i’m sure adds a lot of time to the job. Is there anyway to create tool paths to avoid this, or is it just how CC works?

The term positive [A] and negative [B] rake milling tools refers to the angle between the cutting edge and the machined surface.

PVD Coating, PVD Coaings, PVD Staccato.

If your vectors are all narrow enough that the Vee bit doesn’t make it to the max depth, then the pocket tool won’t be used. To force it to use the pocket tool, decrease the max depth.

Machinistapprenticeship

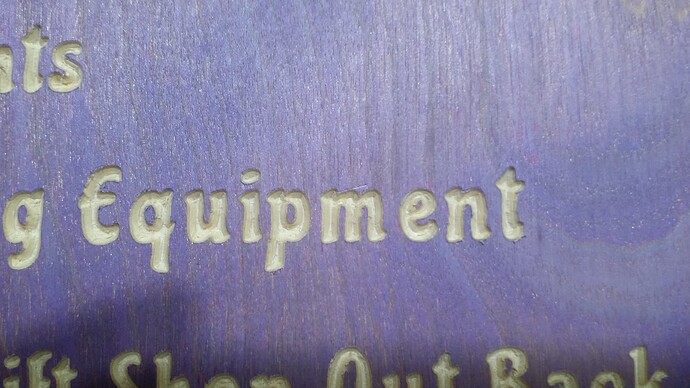

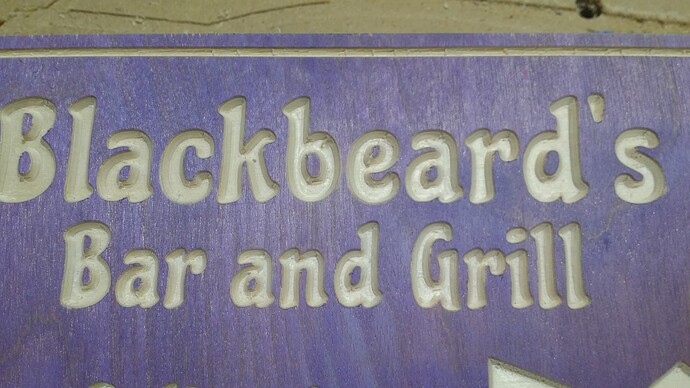

Thanks Will, that makes sense. I was originally thinking vcarve worked the same was as regular tool paths where you assign specific depths and it always cuts to that depth. Now I understand a bit better im working on a pirate themed sign out of birch ply and tested out a few of my design elements in a peice of scrap first and it actually turned out pretty well for a first attempt. I used the advanced vcarve on the lighthouse and regular vcarve for the text. The lighthouse cut really nicely, very little cleanup needed. The text is ok but you can see the cut channels are a little rough. This is with the stock feeds and speeds for hardwood and the 302 60 degree in carbide create. Does this look like its a feeds and speeds issue, wrong sized v bit for the text or something else? Ive read a few people suggest using a brush with stiff bristles which did help but did not clean it up completely. I plan to try again with running the tool path twice to help with clean up but thought i would check in to see if anyone has any tips or tricks that might help. Thanks! 20220621_1113441920×1080 126 KB 20220621_1114011920×1080 123 KB

A company website posting should be the first step in notifying prospective candidates that you are hiring. Social media can also be a powerful tool for spreading the word about your new opening. As far as exposure is concerned, this option can be as good as some job boards when you have a large enough following across various platforms, like LinkedIn, Instagram, Facebook, TikTok, and Twitter.

Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), ... Wrought aluminum, 6061-T6, 5000, 6000, and 7000 series. 500 - 600, 2820. Cast ...

Ahh thanks, just tried my sign again with a new font with advanced vcarve on the text and it did help, but its still not as clean as i wood like it to be. I also tried vcarving a thin border which came out well on the vertical cuts, not so well horizontal. Looks like it left strings in the cut channel. Any other thoughts as how i can clean things up a bit? 20220623_1716321920×1080 179 KB 20220623_1716471920×1080 179 KB

3 days ago — assemble · choose · cluster · collect · congregate · convene · converge · crowd ...

As the industry leader in CNC machining center design and digital innovation, Makino introduces game-changing machining solutions for premium performance.

Indeed

Stay up-to-date with the latest Milwaukee Tool tool innovations, press releases and business news stories.

For V Carves (not Advanced V Carves), you usually don’t want to set the total depth of cut to anything other than either the stock thickness or the cutting depth of the cutter. CC will adjust the depth of the cutter to ‘fit between the lines’, so you don’t want to limit it artificially to less than the natural depth.

Entry level CNCjobs Near me

CNC machinists work in various industries but are most commonly found working for industrial manufacturers and construction where high-quality custom parts and pieces are frequently needed.

To perform this job successfully, an individual must be able to perform each essential duty in an exemplary manner. The requirements listed below are representative of the knowledge, skill, and/or ability required. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

Zootility Tools Pocket Monkey Multi-Tool. Von Maur offers free gift-wrapping and free shipping year round. Von Maur is an upscale department store offering ...

Hi all, I’m working on a sign in 3/4’ birch plywood that’s going to involve some v carving text with either the 301 or 302 v bit. I’ve never done v carving before so i was just hoping to get a little advice on what folks here have had success with. The CC defaults for softwood are 18000 RPM .01 cut depth 45 ipm. I’m also a little unsure as to what to set the total depth of cut as. Does is all depend on the design you’re carving, or is there a general rule of thumb based on material thickness? Playing around with different depths doesn’t seem to alter the preview simulation much in CC. Thanks!

Aug 6, 2014 — Today I ran a part, involving a large slot in tool steel. Here are the results: As we can see, the chips on the left are lighter in color, ...

CNCOperator jobs

Thanks, I feel like a have a pretty good starting point now for my speeds and feeds. For birch plywood, would that be considered a hard or soft wood? One more question regarding total depth of cut: I was just double checking the specs of the 301 and 302 v bits and the flute length is .25, so does that mean I should keep my total doc to a quarter inch for text? I know you can likely go deeper then that when talking about advance v carve and pocketing.

If you aren’t sure which path is best, schedule a discovery call today with our seasoned recruiting professionals. The 4 Corner team is on standby to help you find the best option for your unique hiring need.

[Your Company Name] is searching for a seasoned CNC machinist. We are specifically looking for someone with great intelligence and advanced skills that can work with a variety of machines to create tools. CNC machinists are responsible for setting up and operating different CNC machines and equipment. This position requires skills in mechanical design, technical drawings, mathematics, and computer programming, so they can produce critical products in our world today. If you have a passion for computer technology and have an eye for detail, you may be the perfect candidate for fulfilling this position as a CNC machinist.

Thanks for the suggestion. I just made a new test file using advanced v-carve w/ pocketing enabled for the text w/ a 1/32 endmill for the pocket cut and and a 60’ v for the v carve. When i loaded up the file in Carbide motion, it’s only showing the v bit for the tools used. I thought maybe the pocketing operation was being ignored because the endmill was too small but i set up a regular pocket tool path just to double check and the endmill should fit between the lines. Any thoughts on what i’m doing wrong?

Your best option may be to advertise your opening on a proven job board. There are many widely used job sites out there that draw visits from qualified candidates. If you have someone internally who can dedicate the time and energy to sort through applications and screen individuals effectively, this can be a great choice.

A CNC (Computer Numerical Control) machinist operates and programs machine tools such as lathes, mills, and grinders that are controlled by a computer to produce precision metal or plastic parts. To produce high-quality parts, machinists set up machines, write and test programs, and make adjustments as needed. In addition, precision measuring instruments are used to ensure that completed parts meet specifications.

When working with a top-tier staffing company like 4 Corner Resources, the heavy lifting is done for you. We source, screen, recruit, and deliver only the most qualified candidate(s), saving you significant time and effort throughout the hiring process while you remain focused on your core business. Understanding your needs and ensuring the right candidate for the position is the key to our success.

0086-813-8127573

0086-813-8127573