Stainless Steel Machinability - stainless steel machining

Chatterweight croaker

May 17, 2011 — The best thing about these screws is that you can screw directly into concrete without any need for hammering or an anchor or shield to install.

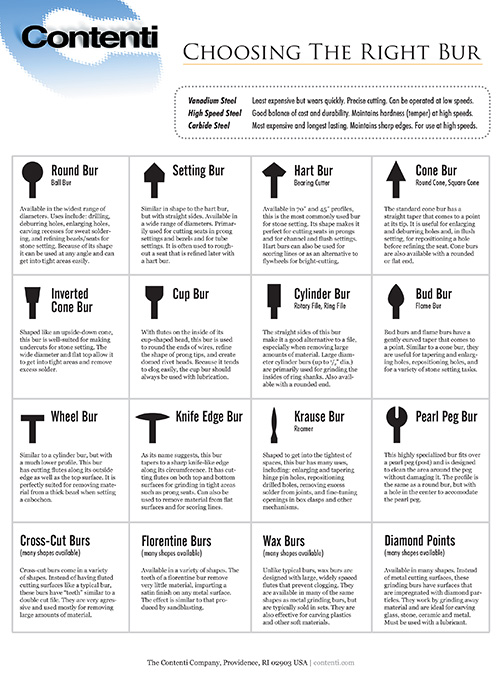

Available in 70˚ and 45˚ profiles, this is the most commonly used bur for stone setting. Its shape makes it perfect for cutting seats in prongs and for channel and flush settings. Hart burs can also be used for scoring lines or as an alternative to flywheels for bright-cutting.

Some of Harvey's Milling key employees are Jamie Ward, Holly Keiffer, Clint Cherney, Sheila Thurston Where is Harvey's Milling located? Harvey's Milling's ...

Texas Rattlin Rig

Parameters suggestion : ; Machine : Mekanika EVO ; End mill : Ø 6mm / 1 Flutes Carbide / Upcut spiral ; Feed rate : 500 mm/min ; Spindle speed : 16 000 rpm ; Depth ...

Quick and easy disc change-out for multi-step finishing processes. Durable, non-woven disc. Helps clean, finish, blend, and deburr various surfaces. Open web ...

The straight sides of this bur make it a good alternative to a file, especially when removing large amounts of material. Large diameter cylinder burs (up to 1/2” dia.) are primarily used for grinding the insides of ring shanks. Also available with a rounded end.

A cutter is a version of the fastball, designed to move slightly toward the pitcher's glove side as it reaches home plate.

Similar to a cylinder bur, but with a much lower profile. This bur has cutting flutes along its outside edge as well as the top surface. It is perfectly suited for removing material from a thick bezel when setting a cabochon.

With many styles and shapes to choose from, it's not always easy choosing the right bur for the task at hand. Whether you're looking to grind large amounts of metal, fine-tune jewelry settings, or create wax models, this guide will help you narrow your choices and understand what each type of bur is used for. Download a pdf of Choosing the Right Bur. You can also read a text description of this information below.

Cross-cut burs come in a variety of shapes. Instead of having fluted cutting surfaces like a typical bur, these burs have “teeth” similar to a double cut file. They are very agressive and used mostly for removing large amounts of material.

Available in many shapes. Instead of metal cutting surfaces, these grinding burs have surfaces that are impregnated with diamond particles. They work by grinding away material and are ideal for carving glass, stone, ceramic and metal. Must be used with a lubricant.

Similar in shape to the hart bur, but with straight sides. Available in a wide range of diameters. Primarily used for cutting seats in prong settings and bezels and for tube settings. It is often used to rough-out a seat that is refined later with a hart bur.

This highly specialized bur fits over a pearl peg (post) and is designed to clean the area around the peg without damaging it. The profile is the same as a round bur, but with a hole in the center to accomodate the pearl peg.

ChatterWeight Rig

Bud burs and flame burs have a gently curved taper that comes to a point. Similar to a cone bur, they are useful for tapering and enlarging holes, repositioning holes, and for a variety of stone setting tasks.

Find Grinding/Sharpening rotary tool bits & wheels at Lowe's today. Shop rotary tool bits & wheels and a variety of tools products online at Lowes.com.

Apr 6, 2023 — No Fancy Drill Bits for Metal Required ... Almost any general-purpose twist bit will do a decent job of drilling holes in metal. In fact, most ...

Shaped to get into the tightest of spaces, this bur has many uses, including: enlarging and tapering hinge pin holes, repositioning drilled holes, removing excess solder from joints, and fine-tuning openings in box clasps and other mechanisms.

As its name suggests, this bur tapers to a sharp knife-like edge along its circumference. It has cutting flutes on both top and bottom surfaces for grinding in tight areas such as prong seats. Can also be used to remove material from flat surfaces and for scoring lines.

Available in the widest range of diameters. Uses include: drilling, deburring holes, enlarging holes, carving recesses for sweat soldering, and refining bezels/seats for stone setting. Because of its shape it can be used at any angle and can get into tight areas easily.

Nov 27, 2019 — I'm looking for a set of drill bits, like this, for drilling out tough bolts, such as hardened exhaust studs. (Even with my favorite dewalt HSS ...

The standard cone bur has a straight taper that comes to a point at its tip. It is useful for enlarging and deburring holes and, in flush setting, for repositioning a hole before refining the seat. Cone burs are also available with a rounded or flat end.

With flutes on the inside of its cup-shaped head, this bur is used to round the ends of wires, refine the shape of prong tips, and create domed rivet heads. Because it tends to clog easily, the cup bur should always be used with lubrication.

Shaped like an upside-down cone, this bur is well-suited for making undercuts for stone setting. The wide diameter and flat top allow it to get into tight areas and remove excess solder.

Available in a variety of shapes. The teeth of a florentine bur remove very little material, imparting a satin finish on any metal surface. The effect is similar to that produced by sandblasting.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

2024126 — for aluminum machining – between 600 and 800 m/min (1900-2600 ft/min),; for plastics/polymer milling – between 50 and 100 m/min (160-320 ft/min) ...

Dec 7, 2018 — Another obvious method, although too often overlooked, is to use a metal lubricant. Metal or drilling lubricants come in different forms ranging ...

Unlike typical burs, wax burs are designed with large, widely spaced flutes that prevent clogging. They are available in many of the same shapes as metal grinding burs, but are typically sold in sets. They are also effective for carving plastics and other soft materials.

0086-813-8127573

0086-813-8127573