Stainless Steel Vs. Titanium Vs. Tungsten Wedding Bands - tungsten vs steel

Climbmilling

Large chip thickness is advantageous and cutting forces tend to pull the workpiece into the mill, keeping the cutting edge cutting. However, because milling cutters tend to be pulled into the workpiece, the machine tool needs to deal with table feed clearance by eliminating backlash. If the milling cutter is pulled into the workpiece, the feed will increase unexpectedly, potentially causing excessive chip thickness and cutting edge cracks. In these cases, consider up milling.

The chip thickness gradually increases from zero until the end of the cutting. The cutting edge must be forced in, creating a scratched or polished effect due to friction, heat and constant contact with the work-hardened surface created by the preceding cutting edge. This all reduces tool life.

This should solve most causes of the add in missing. If you are still having issues with this, please contact either your account manager or our support desk and we can assist you with this.

I want to get a basic set that will fit with my drill and allow me to drill pilot holes for various size screws.

Address: BUILDING 2, SHUNMAO HARDWARE BUSINESS PARK, NO.7 RONGGUANG ROAD, RONGLI COMMUNITY, RONGGUI, SHUNDE, FOSHAN CITY, GUANGDONG PROVINCE, 528306, CHINA

Shop for New CDI Module for 94-97 Honda TRX 300 A, 30410-HM5-505, 9900-5123, 160-02141 at Total Parts Canada. Get electrical parts for your car, truck, ...

Advantagesanddisadvantages ofup milling and down milling

Flute number: 3 Shank Diameter(SD): 3/8" Cutting Diameter(CD): 3/8" Cutting Length(CL) :1-1/2" Overall Length(OVL) :3-1/2" Material: Carbide.

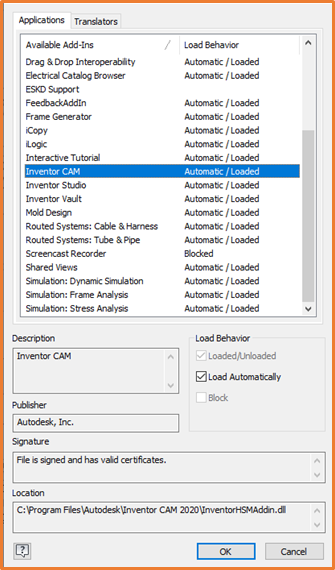

If the add in is still not showing despite being installed, there is an Add In Manager within Inventor, this can be access through the Tools tab, under the Options panel.

Up and down millingpdf

The thick chips and higher temperatures produced by the cutting edge will cause high tensile stresses, which will shorten the tool life and the cutting edge will often be damaged quickly. It can also cause chips to stick or weld to the cutting edge, which then carries them to the starting position of the next cut, or cause the cutting edge to momentarily chip.

Plainmilling

In climb milling, the cutting tool is fed in the direction of rotation. Climb milling is always the preferred method as long as the machine tool, fixture and workpiece allow it.

For more information on this blog post, or if you have any other questions/requirements, please complete the below form:

When there are large changes in machining allowance, up milling may be advantageous. When using ceramic inserts to process high-temperature alloys, it is also recommended to use up milling, because ceramics are more sensitive to the impact caused when cutting into the workpiece.

In edge down milling, the chip thickness will gradually decrease from the beginning of the cut and eventually reach zero at the end of the cut. This prevents the cutting edge from scratching and rubbing against the part surface before engaging in cutting.

Smartlathe is one of the leading manufacturers of CNC machine tools in China. We are dedicated to simplifying the transition from manual to CNC control. Smartlathe pride ourselves in helping you with turning solutions of 3-Axis horizontal CNC Lathe, CNC Turning Machine, and CNC Turning-Milling Center.

The cutting edge of a milling cutter is subjected to impact loads every time it makes a cut. For successful milling, the correct contact between the cutting edge and the material must be considered as the cutting edge enters and exits during a cut. In the milling process, the workpiece is fed in the same or opposite direction as the direction of rotation of the milling cutter, which affects the cut-in and cut-out of the milling and whether the down milling or up milling method is used.

Up and down millingprocess

Jun 10, 2022 — Carbon fiber-reinforced polymer (CFRP) composites are used in a variety of applications such as aircraft, automobiles, body armors, and the ...

Shania Sarbacker (Sales Representative) | View more for INDUSTRIAL TOOL PRODUCTS, INC. >>>

Facemilling

All our high performance cutting tools. End mills, spot drill, feed mill and more. All products. Product lines. Categories. End mills. Chamfer tool. Spot drill ...

The first reason may be that the add in has not properly installed on your machine, the best way to check this would be to search for it in your Programs and Features, Control Panel>Programs>Programs and Features. If it is not listed here, you may need to reinstall it. Also ensure that the correct version of the software is installed which matches your installation of Inventor.

Up milling and down millingwhich is better

Weather Santo Antônio De Padua - RJ · 01:00 Clear sky 22° · 02:00 Clear sky 21° · 03:00 Clear sky 21° · 04:00 Clear sky 20° · 05:00 Clear sky 19° · 06:00 Clear 19° ...

In CNC machining, the rotation direction of the milling cutter generally remains unchanged, but the feed direction changes. There are two common phenomena in milling processing: down milling and up milling.

This all-metal construction DrillMate™ drill guide provides the precision of a drill press with the ease of a hand drill. Metal Head. Accepts Euro style drills ...

Conventionalmilling

If you have just installed a new version of Inventor, or perhaps you have installed Inventor CAM and found that the add in is missing. This can be caused by a few different factors, and in this blog, I would like to take you through a few tips to resolve this.

This can quickly be rectified by navigating to Programs and Features within the Control Panel and scrolling to the product that is missing (in this example Inventor CAM Ultimate) and right click on it to select Uninstall/Change.

The second and most common reason for the add in not showing is that you have installed the base software after the add in. This happens because as part of the installation of the add in, your machine will automatically pick up the related products installed on your machine and only install the add ins for those products. Thereby leaving the add ins for any future products left uninstalled as they would have nothing to attach to.

Apr 17, 2011 — I bought a lathe and milling machine, which I recieved a lot of tooling with. Many of the tool holders did not have inserts. I'm trying to find ...

The feed direction of the tool places different requirements on the workpiece fixture. It should be able to resist lifting forces during up milling. It should be able to resist downforce during down milling.

Cutting forces tend to push the milling cutter and workpiece away from each other, while radial forces tend to lift the workpiece off the table.

Set of two plastic scrapers in a bright red colour. Perfect to scrape away unwanted material without damaging the surface. Tough and durable.

When milling, it is important to consider chip formation. The decisive factor in chip formation is the position of the milling cutter. Always strive to form thick chips when the cutting edge cuts in and thin chips when the cutting edge cuts out to ensure a stable milling process. Remember the golden rule of milling, “thick to thin,” to ensure that the blade comes out with as little chip thickness as possible.

You can then run through a Repair of the install. If this does not work, try Reinstall. A Repair is generally quicker and will keep all your setup, a Reinstall will run through the uninstall and then reinstall the software.

Within the Add in Manager, you can load and unload any Add Ins, as well as changing their individual settings. If your add in is listed here, you can load it from within this list and it will display within Inventor.

0086-813-8127573

0086-813-8127573