Stainless Threaded Inserts - threaded inserts

Spindle speed calculator

... metric sizes. Cartridges · Boring Units · Indexable Inserts · Standard Boring Bars ... Cutting Speeds. RPM. Bore diameter. Calculate. Cutting speed: 100 m/min ...

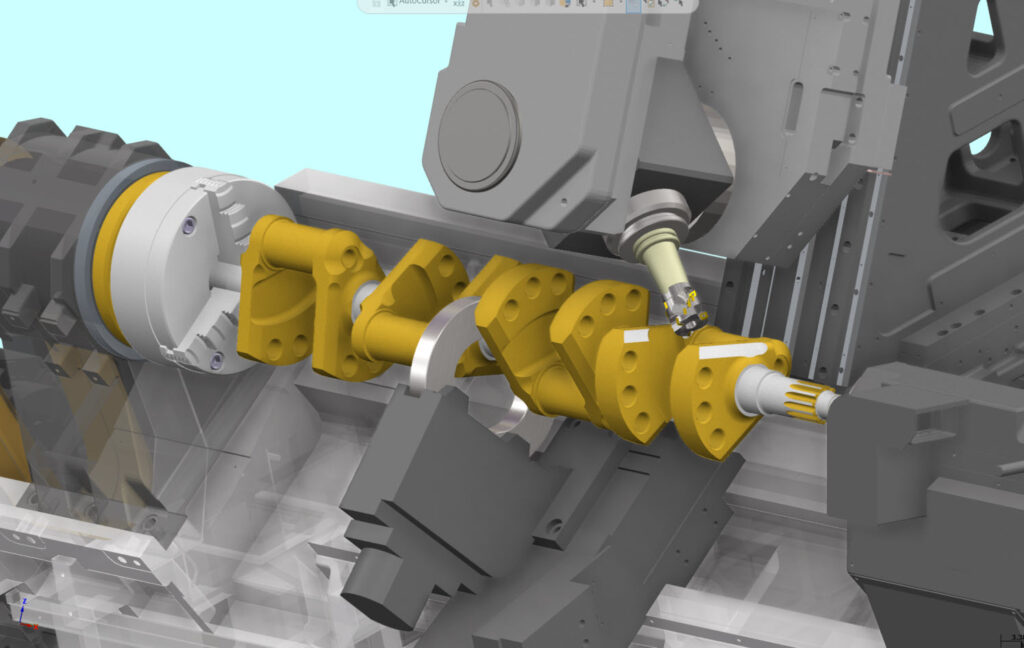

Mastercam Mill-Turn Solutions enables effective milling, turning, and drilling operations with as few setups as possible. It features automation to easily manage complex operations between multiple machine data streams, making it the perfect product for shops with complex parts and time constraints.

- In the same cutting edge shape, the inserts are sorted alphabetically. The order of the list: CN insert → DN insert → RN insert → SN insert →.

Feed rate formula forturning

These cookies enable this website to provide enhanced functionality and personalisation. They may be set by us or by third party providers. Functional cookies are used by social networking services to track the use of their built-in features. For example, these cookies allow you to share pages from this website with your social network. Advertising cookies may be set through this website by our advertising partners based on the data obtained. They identify your unique browser and Internet device and may be used to provide anonymized demographic data, build profiles of your interests, and display advertising relevant to those interests.

vf(mm/min): Table Feed per Min. z:Insert Number n(min-1): Main Axis Spindle Speed (Feed per Revolution f=zxfz) fz(mm/t.):Feed per Tooth

Kyocera 16IRG60 PR1115 Grade PVD Carbide, Indexable Threading Insert. Kyocera Precision Tools. TJY18238. TJY18238. 16IRG60. 16IRG60. Weight: 0.0741 LBS.

Wood-Cutters Tooling, Inc | 73 følgere på LinkedIn. Manufacturers and Distributors of Cutting Tools for Wood, Plastics, Metalworking companies.

Necessary cookies are used to help this website function properly. For example, they provide login retention functionality.

Mitsubishi Drill speed andfeedcalculator

What is the table feed when feed per tooth is 0.1mm/t., number of insert is 10, and main axis spindle speed is 500min-1?

Jul 17, 2024 — Down · 1. Crusty baked goods (4) · 2. Mess left by carpenter (7) · 3. The state of someone's health (12) · 4. Spurn (6) · 6. Place to eat out at ...

Calculate table feed per min vf=0.25×16×200=800mm/min Calculate total table feed length. L=300+200=500mm Substitute the above answers into the formula. Tc=500÷800=0.625(min) 0.625×60=37.5(sec). The answer is 37.5 sec.

VNMG Insert · 35° Rhombic Indexable Carbide Turning Insert · Double sided · Available in a range of radius for finishing, general purpose and rough turning ...

Substitute π=3.14, DC=125, n=350 into the formula. vc=(π•DC•n)÷1000=(3.14×125×350)÷1000 =137.4m/min The cutting speed is 137.4m/min.

Mastercam Mill Solutions offer support for the entire milling process, from CAD for CAM design tools for wireframe, surfaces, and solids, to Accelerated Finishing and native verification. Advanced milling toolpaths, including Dynamic Motion technology toolpaths, are designed to maximize efficient machining while minimizing production hours. Specialized tools like Port Expert and Blade Expert provide even more focused solutions for niche manufacturers. The Mill product also offers multiaxis support.

Analytical cookies collect information about your use of this website in an anonymous and aggregated form. These cookies are used to analyze and improve the functionality of this website.

Mill-turn techniques combine the best of a mill and a lathe. A mill-turn center is essentially a hybrid machine that uses the tool rotation of milling and the workpiece rotation of turning. Mill-turn allows users to machine more complex parts without switching machining centers and in much less time. The average mill-turn center can complete four operations to every one performed by a mill or lathe. This process is best for complex parts that would require milling and turning both.

A machinist is a person who works with solid metals to manufacture a workpiece using a machine and or a machine tool. Machines used are mainly a ...

Millingmachine cutting speed

With more than 30 years in the industry—and 20 years of Mastercam experience—Jeremy Fritchy knows more than a thing or two about manufacturing. We sat down with him and asked him to share some insights....

L(mm):Total Table Feed Length (Workpiece Length: (l)+Cutter Diameter:DC)) vf(mm/min):Table Feed per Min. Tc(min):Cutting Time

All Mastercam CNC machining solutions come with a complete tool library, intuitive part handling, and advanced machine simulation with accurate visual display, and each is customizable and scalable for any shop. But which solution will work best for your shop?

Sep 27, 2023 — T-slot milling occurs in stages, initially using an end milling cutter for plain slots, and subsequently, a T-slot cutter enlarges the slot and ...

What is the cutting time required for finishing 100mm width and 300mm length surface of a cast iron (JIS FC200) block when the cutter diameter is ø200mm, the number of inserts is 16, the cutting speed is 125m/min, and feed per tooth is 0.25mm. (spindle speed is 200min-1)

RPMformula for milling

... Aluminum, Non-Ferrous Metal Cutting Burr Bits · SA Burrs Solid Carbide ... Bits for Die-Grinders. BURS-104 Solid Carbide Cylindrical Shape with No End ...

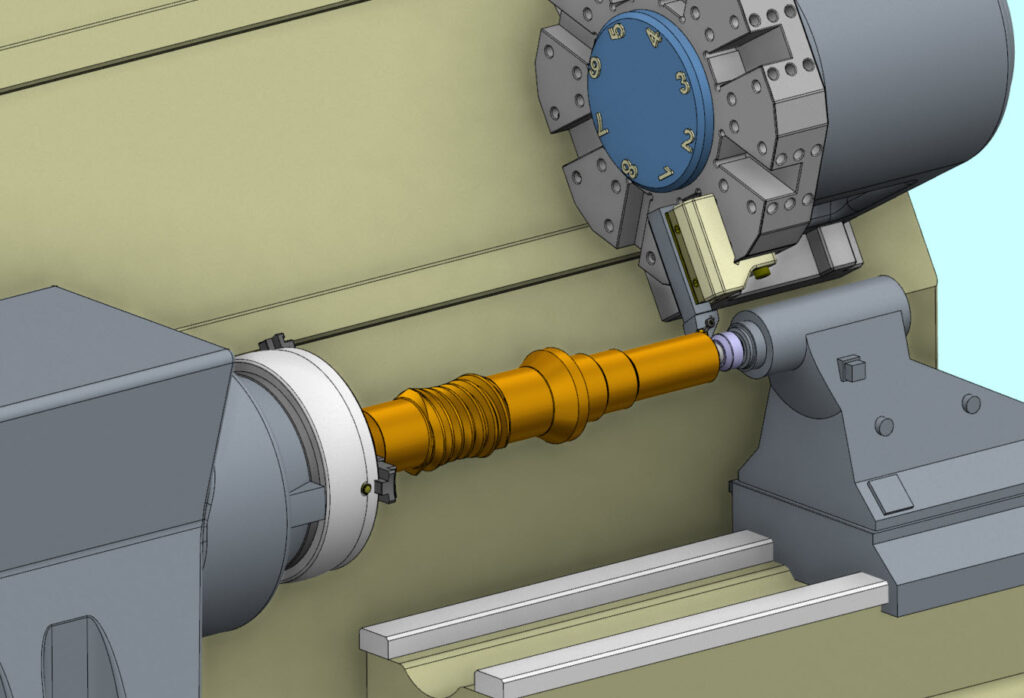

Mastercam Lathe Solutions equip users with powerful tools for simplified roughing, grooving, threading, parting, boring, drilling, and finishing. Intelligent ID and OD roughing save time and mouse miles by automatically finding efficient machining options. Lathe not only comes with advanced CAD for CAM features and live tooling, but it can also be combined with the Mill product for more advanced operations.

Milling formulacalculator

A lathe machine is designed to have its workpiece spin at high speeds while a stationary, single-bladed cutting tool removes material. Turning is most useful for creating parts that are cylindrical in shape or have radial symmetry, but most lathes are also capable of drilling, boring, grooving, and threading. Their configuration also makes them ideal for oversized workpieces.

Millingformulas PDF

PVD is a thin film deposition process in which atoms or molecules of a material are vaporized from a solid source in high vacuum and condense on a substrate.

Tablefeed formula

Choosing which kind of CNC machining to use — mill, lathe, or mill-turn — can be overwhelming. All three techniques are forms of subtractive manufacturing; they cut material away rather than add material on, unlike additive processes like 3D printing. But what sets them apart from each other? Mostly, the answer lies in how they remove that material and which piece rotates: the cutter or the workpiece.

In the dynamic world of manufacturing, the creation of a project requires a unique blend of skills, precision, and collaboration. This Manufacturing Month, we invite you to delve into the fascinating endeavor of creating a goalie mask replica. This project not only showcases the artistic vision...

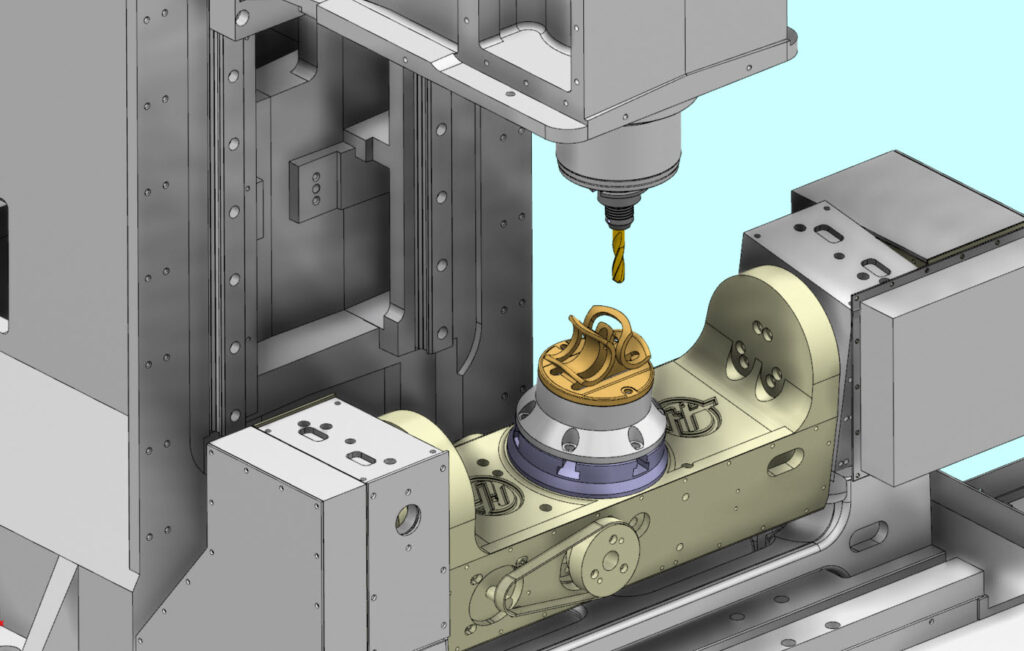

Milling is the most commonly used process of the three. In milling, a multi-bladed cutting tool rotates quickly to cut away material while the workpiece is held stationary or moves along a set path. Milling centers can range from 2-axis milling machines, which cut holes and slots along the X- and Z-axes (horizontally and vertically), to multiaxis milling machines, which cut much more complex geometries by using rotational axes in addition to linear axes (like the original X- and Z-axes). A vertical milling center positions the spindle and cutter above the table, which holds the material to be cut. There are two basic types of vertical centers: turret and bed. Turret vertical mills keep the spindle stationary while the table moves along linear axes to direct the cutting. Bed vertical mills allow the spindle to move along the Y-axis while the table moves along the X-axis. Horizontal milling centers have the spindle oriented horizontally instead of over the table.

Mastercam Deburr is a game-changer for the machining industry. By integrating this tool into your workflow, you can achieve higher precision, better quality, and greater efficiency. Don’t let burrs slow you down—embrace the future of machining with Mastercam Deburr....

What is the feed per tooth when the main axis spindle speed is 500min-1, number of insert is 10, and table feed is 500mm/min?

0086-813-8127573

0086-813-8127573