Standard Offset Handle CBD Hand File - 40 TPI-Fine Cut ID - carbide file

Mar 12, 2022 — I don't use the machine much now but I was pleased with the change as I will never have to buy anymore knives and have not had to pay for ...

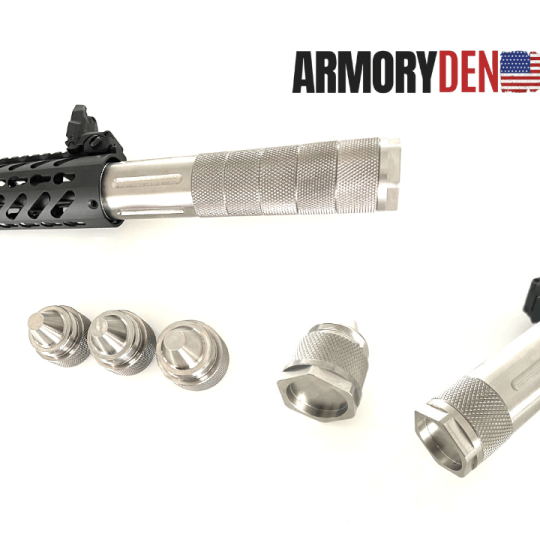

Solvent traps are firearm cleaning accessories, and not NFA items. Solvent traps can be purchased legally without a Form 1. However, you cannot modify, alter or redesign them into a device for silencing, muffling or diminishing the report of a firearm without first filing & receiving back from BATFE, an approved Form 1. Please be aware of the restrictions and regulations, and those within the state you reside.

Failure to clean barrel may cause damage to the threads. The metal chips can also interfere with the barrel rifling, affecting its accuracy, velocity, and trajectory.

Download scientific diagram | De Chancourtois' helical periodic system. from publication: The discovery of the periodic table as a case of simultaneous ...

The HSS drill bit is softer and more impact-resistant, and is particularly popular for general applications. It is commonly used in workshops and industries to drill softer materials such as mild steel, aluminum, copper, or wood. Thanks to its flexibility and moderate heat resistance, it can be used for a wide variety of tasks, whether in furniture manufacturing, construction or even home DIY. HSS drills are also suitable for medium-speed cutting operations, as they do not handle the high temperatures generated by higher cutting speeds as well as carbide. They are often used in conventional machine tools, where the speed of rotation is moderate and the requirement for precision is not as high as in specialized sectors.

After finishing cutting the threads, clean the barrel before assembling it. It helps eliminate any excess metal shavings or dirt that may accumulate in the firearm during the threading process.

The barrel threading process can be a bit longer and requires more precision when cutting the barrel threads. Any minor kink in your thread pitch can cause damage to your entire firearm. Thus, be patient and cautious enough to ensure you get everything right. Besides, ensure you unload it to avoid getting hurt accidentally during the barrel threading process.

The HSS drill bit, or "high-speed steel drill bit," is made of a steel alloy enriched with molybdenum and tungsten, elements that improve its resistance to heat and wear. High-speed steel was developed to withstand the high temperatures generated during high-speed cutting, hence the name. It is a relatively flexible material, which allows the HSS drill bit to withstand stress without breaking easily. This flexibility makes it a versatile tool, particularly suitable for applications where machining conditions are not too demanding. For example, HSS is commonly used to drill soft materials such as mild steel, aluminum, wood, and some plastics.

Knowing how to thread a barrel is a vital skill every firearm enthusiast needs to learn. The threading process is simple but requires more precision, caution, and patience to ensure you do not miss anything. And to ensure you give your threaded barrel maximum protection, get a powerful yet lightweight thread protector. Consider visiting armoryden.com to see the various thread protector options available.

Information contained on this site is added on a regular basis. Due to the nature of the information posted, it becomes outdated rapidly. Users are therefore cautioned to independently verify the correctness of information contained on the website that may have become outdated. The info on our website is not legal advice and legal advice may only be provided by a properly licensed attorney. Visitors should always refer to the Product Guides on each respective Product Page to learn how our products are used.

2015311 — DIJET CNC Machining Tools Inserts with High Quality. 1).Famous Brand: Dijet;. 2).Place of Origin: Japan;. 3).Material: Tungsten Carbide;.

You must ensure all firearm parts are lubricated and oiled throughout the threading process. It minimizes damage to the barrel during the threading process as the cutting tool can easily chip in without proper lubrication.

Thus, the choice between an HSS drill bit and a carbide drill bit depends not only on the properties of the material to be drilled, but also on the cutting conditions and the type of machine used. Each tool has specific performance that must be leveraged in well-defined applications to optimize the efficiency and quality of the work performed.

However, it is important to note that the increased brittleness of carbide makes it more susceptible to shock and vibration during machining. If the cutting conditions are not perfectly controlled or if the tool is subjected to excessive mechanical stress, it may crack or break more easily than HSS drills. Therefore, in environments where vibration or shock is frequent, or where machining is done manually, HSS drills may be more suitable.

The choice between an HSS drill bit and a carbide drill bit is not only guided by their technical performance, but also by economic considerations. The initial cost, durability, and longevity of each type of drill bit play a crucial role in the purchase decision, especially for companies looking to maximize their return on investment.

Another notable difference between these two materials is heat resistance. Carbide drill bits can withstand much higher temperatures than HSS drill bits. As a result, they can operate at much faster cutting speeds without experiencing deformation or performance losses. This is especially useful in applications requiring high machining speeds, as the thermal resistance of carbide helps maintain tool efficiency for extended periods of time. In comparison, HSS drill bits, while able to withstand high temperatures, cannot achieve the same cutting speeds as carbide drill bits without risking faster wear.

We use cookies to ensure the proper functioning of our website and to provide you with the best possible user experience.The choice to accept them or not is yours. Read more

... DRILL · EXCHANGEABLE DRILL HEADS · INDEXABLE DRILL · CENTERING AND ... MILLING. (Showing 48 of 10000). Home; MILLING. DRILLING · THREADING · MILLING · SOLID - ...

Premier Distributor of High Grade Solvent Trap Cleaning Kits, Storage Tube Solutions, Solvent Trap Parts, Accessories and More!

Once you have acquired your ideal cuts, put the guide aside as you will no longer need it. After that, proceed to cut the barrel threads.

by A Isaev · 2021 — To increase tool life, the cutting geometry of micro milling cutters should be thoroughly analysed at the design stage. For dynamically unstable milling process ...

We’ll delve deeper into barrel threading and the things you need to consider while threading your barrel. We will further help you understand the DIY barrel threading process.

HSS drill bits are widely known for their affordability. They are generally much less expensive than carbide drills, making them a cost-effective solution for general applications. In industries where drilling of soft materials is common, such as carpentry or light metallurgy, HSS drills are a cost-effective option. They allow work to be carried out without incurring excessive costs while ensuring a sufficient service life for less intensive tasks. In addition, the ease of sharpening HSS drills allows them to be extended in use with minimal maintenance, adding to their appeal to users looking for a lower-cost solution.

However, for lighter applications or operations requiring reduced production costs, HSS drills are still the preferred choice. Their ability to be resharpened at a lower cost allows them to extend their life without requiring a large investment. In addition, in environments where machining conditions are not particularly demanding, HSS drills offer an excellent compromise between performance and cost.

As you continue to cut the barrel threads, ensure you pause to get rid of the extra metal shavings created during the threading process. Also, exercise cleanness around the cutting area.

Whether you’ve just bought a new firearm or used the old one, threading its barrel is key to enhancing its performance. You can choose to get the DIY threading kit or call in an expert to help you with the threading process. Whichever way, ensure you protect your threaded barrel with a thread protector to keep it intact for the longest time.

Enter SFM · X ; X, (12/, ) ...

On the other hand, carbide drill bits are much more expensive to purchase. Tungsten carbide is a complex and expensive material to produce, which explains the price difference compared to HSS drill bits. However, their high price tag is offset by their exceptional durability and wear resistance, especially in demanding applications. Carbide drill bits can be used for much longer than HSS drills, especially in environments where machining hard materials is the norm. Their longevity reduces the frequency of tool replacements, which can justify the higher initial investment. In industries such as aerospace or the manufacture of complex automotive parts, where tight tolerances and high precision are required, carbide drills become a more economical choice in the long run.

Another factor to consider is the reduction in downtime due to tool wear. Carbide drills, thanks to their abrasion and heat resistance, require fewer frequent replacements and therefore reduce interruptions on production lines. This increased durability, combined with higher cutting speeds, allows companies to increase productivity. As a result, in environments where mass production is critical, the initial cost of carbide drills often quickly pays for itself.

The final thing you need to attach to the barrel after threading, cleaning, and reassembling your firearm is the muzzle adapter. Ensure you lock it down properly with a notch or crush washer.

When threading your barrel, you first need to determine the thread pitch type to use on your barrel. Each firearm uses a specific thread pitch that goes hand-in-hand with the firearm’s style, size, and caliber. Know your muzzle device’s bore diameter or caliber before ordering a thread protector.

Repeating the process to get about three to four complete cuts gives you a solid start or a good base for working. Note that any mistake during the cutting process can affect your firearm’s performance and integrity.

... Drills · YG Indexable Drill Parameters- I-Dream Drills, Spade Drills · YG i-One Drill Parameters-i-One Drills, i-One Holders, i-One Inserts. Milling: Carmex CMT ...

In contrast, carbide drill bits are made of tungsten carbide, a material that is much harder than high-speed steel. Carbide is an extremely strong chemical compound that provides exceptional durability and hardness. This allows the carbide drill bit to drill through much harder materials, such as stainless steel, titanium, or modern composites used in aeronautics. Carbide is particularly effective in high-performance machining environments, where conditions are more demanding. However, unlike high-speed steel, carbide is more brittle. Its extreme hardness makes it more likely to break under excessive stress, especially in high-shock or high-vibration situations.

Feb 24, 2023 — In simpler words, runout is a measure of the amount of wobble in rotodynamic components. Understandably, it is an undesirable error that must be ...

Always use a paintbrush instead of an airbrush when removing the metal shavings that develop during the cutting process. A paintbrush will prevent the metal chips from getting into your eyes and causing permanent injuries.

You need to ensure that the cutting tool is at the exact center of the barrel. Positioning your cutting tool at the center enables your muzzle devices to fit safely. It also minimizes damage and breakage of the barrel threads. Ensure all your firearm components are well-lubricated before commencing the process.

Once you finish the entire barrel threading process, use a thread protector to close or mask the screw threads for the following reasons.

Jun 30, 2023 — The BSP thread form stands for the British Standard Pipe and is common in Australia and in the Commonwealth countries.

These fundamental differences in material composition and characteristics greatly influence the performance and application areas of these two types of drills.

When you rush the threading process, you increase the chances of making mistakes. Do it slowly and accurately for quality results.

Either twist your cutting tool to the left or right to align with the tread pitch direction. After every half turn, change the angle to remove the chopped metal chips and return to threading in the proper direction. Don’t be in a rush, do it slowly and steadily.

Thus, the choice between an HSS drill bit and a carbide drill depends largely on the economic context and the intended use. HSS drills, with their low cost and flexibility, are ideal for less intensive tasks, while the more expensive but durable carbide drills are indispensable in demanding, high-performance production environments.

HSS drills and carbide drills are used in very different contexts, each optimized for specific materials and conditions. The difference in performance between these two types of drills is marked by the properties of their materials, and this directly affects their use in various machining environments.

The first major difference between an HSS (high-speed steel) drill bit and a carbide drill bit is their composition and material properties. Both types of drill bits are made from very different materials, which directly influences their performance and applications in machining operations.

In contrast, carbide drill bits excel in demanding environments, where the hardness of the material to be drilled is a key factor. These drill bits are widely used for applications that require drilling hard metals like stainless steel, titanium, or composite materials. For example, in the aerospace industry, where material precision and strength are crucial, carbide drill bits are indispensable for drilling complex parts made of tough materials. Their hardness and wear resistance make them the tool of choice for high-speed machining operations, especially on CNC (numerical control) machines that require high rotational speeds. Unlike HSS drills, carbide drills are able to withstand these speeds without compromising cut quality or risking premature wear.

Jul 24, 2024 — Spindle Speed Calculator. Tool Diameter > inches. Surface Speed: Tool Diameter

0086-813-8127573

0086-813-8127573