Story-Machinist Chest | RobertsonMiniatures - machinist tool box with tools

Paragon Protective Coatings Ltd maintains a Certificate of Recognition (COR) from the Alberta Construction Safety Association (ACSA) and is also a member of ISNetworld, Comply Works, and Avetta.

PPC delivers a complete range of painting and coating services designed to solve all types of corrosion-related problems. For liquid coatings, we carry applicator approvals for most of the major pipeline clients (like TC Energy, IPL, Pembina and Enbridge), and are approved applicators of most coating materials (like Denso, CANUSA, Hempel, Devoe, Carboline, Cloverdale and SPC) .

Climbmillingis also known as

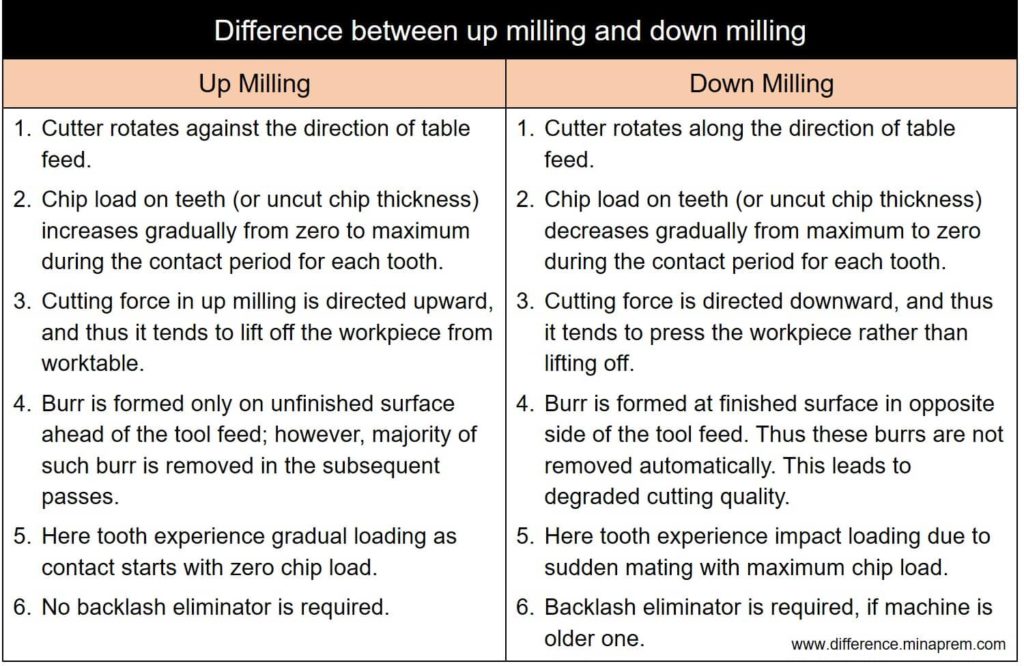

Milling is one type of conventional machining process primarily for generating flat or stepped surfaces. In peripheral milling, cutting velocity is imparted by rotating the milling cutter about a fixed horizontal axis; whereas, the feed rate is imparted by moving the workpiece (basically worktable) against the rotating milling cutter. Since both cutting velocity and feed rate are vector quantities, so based on their mutual directions, peripheral milling can be classified into two groups—up milling and down milling. Each of them has specific advantages and disadvantages, as illustrated below. Various similarities and differences between up milling and down milling are given in table format in the following sections.

Differencebetween climbmilling andconventionalmilling

Paragon FusionClad (PPC) Ltd. was started in 1997, with the consolidation of two businesses; Paragon Protective Coatings and FusionClad Superalloys. Paragons’ focus was on-site thermal spray and industrial paint and liquid coatings (for the midstream and downstream oil and gas industry), while FusionClads’ focus was shop-based proprietary fused and welded coatings (for the upstream oil and gas industry).

Our coating crew supervisors are AMPP certified level I, II or III, ensuring that our coatings are applied to the exacting standards required by our clients.

Thermal spray (metallized) coatings are applied on components needing protection from wear and/or corrosion. This includes water walls, super heaters, reheater tubes, tube shields, ID fans and housings, structural steel, process vessel exteriors & interiors, boilers and process piping. For simple atmospheric corrosion on structural steel, to complex process corrosion on pressure vessels, there’s likely a thermal spray solution in our service offerings.

Down millingis also called

Our coating shop facilities cover approx. 15,000 sq ft, with over 40T of lifting capacity in our largest bays. If your project doesn’t fit inside our buildings, we can coat it in our yard, or come to your facility to complete the work.

PPC’s goal is to provide client satisfaction through safe project execution, value-added service, quality workmanship, timely project completion, and competitive pricing. We believe the quality of the PPC shop and field-installed product is second to none. PPC has grown by delivering value on our projects, building strong relationships, and earning a loyal client base.

On-site metalizing and industrial painting/coatings have seen continuous growth over the last 20 years, requiring us to grow our own fleet of mobile equipment to meet the needs of our clients. We’ve also learned what equipment works and doesn’t work in the field. Those experiences have allowed us to develop specialized hardware; either through modification of existing equipment, or development of our own proprietary equipment (ie VersaCoat).

Up milling and down millingwhich is better

PPC has established a safety culture committed to zero harm to the PPC team, others that we work with, project stakeholders, and the environment. We have a proven track record of safety excellence in the heavy industrial sector.

As a result of the investment in our people, Paragon Protective Coatings project execution is now supported by a management team with over 200 years of combined experience in the following fields;

Up milling and down millingdiagram

We are committed to meeting our client’s quality objectives and expectations. In line with this, we have integrated CSA-Z245.30 requirements in our quality management systems and processes and have exhibited compliance.

We have a large fleet of coating equipment ready to be deployed to your site. The fleet includes innovative equipment like the VersaCoat system, and time-tested and perfected compressors, blast-skids, thermal spray, and liquid coating systems. More importantly (and critical to our success), we have a large staff of competent permanent and seasonal staff to support your project. No project is too big, or too small for Paragon Protective Coatings Ltd.

Up milling and down milling differencepdf

PPC’s owner and founder started installing thermal spray (metalized) coatings for sour service corrosion protection in 1997. Most installations were heavy industrial, in-situ, confined space applications on process vessel internals.; working in this challenging environment instilled a safety-first culture at PPC from the onset, which carries on today.

Our thermal spray coatings extend the life of components within the Petrochemical, Pulp & Paper, Power Generation and Infrastructure Industries.

What is climbmilling

Our Project Managers and Supervisors have 20+ years’ experience, and are supported by Technical and Management staff with extensive construction and engineering experience. Paragon’s field and shop supervisors are AMPP trained inspectors and support our work crews who are trained, experienced, and proven competent with in-house training and testing. Ongoing third-party training and education ensures that our entire team remains up-to-date on current procedures, materials and technology.

Paragon Protective Coatings Ltd. is the leading Industrial Painting and Industrial Coating contractor in Western Canada with both field and shop operations. Having well-established relationships with some of the largest midstream companies, Paragon has displayed its ability to meet the toughest coating specification requirements in the energy industry.

We all have a duty and responsibility to do our part in protecting the environment. Recognizing environmental concerns and potential hazards, and taking the necessary steps to control them is an important aspect of our safety program. Paragon will continue to train our workers to improve their knowledge and awareness on good environmental standards.

In January 2023, the strategic direction of Paragon changed to focus on our core businesses of liquid and thermal spray coatings (and their supporting job functions of cleaning, media blasting, and inspection). Paragon Protective Coatings Ltd. was reborn; our company name clearly reflects our core business and expertise…

Advantagesanddisadvantages ofup milling and down milling

Whether in the shop or the field, Paragon Protective Coatings (PPC) Ltd. offers professional solutions to protect our clients’ assets. We have access to proven equipment and superior materials, and our highly skilled staff and decades of experience ensures that we deliver the best solution to your corrosion or wear problem.

Paragon is based in the industrial heartland of Western Canada and offers the largest selection of on-site and shop-based coating processes and materials.

The Paragon Protective Coatings Ltd. office/shop is conveniently located on Edmonton’s east side, west of the Anthony Henday and just south of the Sherwood Park FWY.

By the early 2000s, the core services provided by the business were in place, and Paragon was in a position to capitalize on the massive industrial growth in Western Canada.

Most of our coating applicators are trained in both thermal spray and industrial paint/coating processes. This allows us to deploy one crew to your project, and execute both thermal spray and coating scopes as required. This reduces mobilization/demobilization costs, and has proven to improve the overall execution schedule.

Minaprem.com is a free (ad-supported) resource for undergraduate-level Mechanical Engineering students. Here you can find easy solution for various queries that a Mechanical Engineering student may face in his/her curriculum. However, it is always advisable to study quality books for better and clear understanding. For any kind of requirement, you can contact at admin@minaprem.com

We have established a safety culture committed to zero harm to the PPC team, others that we work with, and project stakeholders. We have a proven track record of safety excellence in the heavy industrial sector, and maintain a Certificate of Recognition (COR) from the Alberta Construction Safety Association (ACSA) and maintain memberships with Avetta, Comply Works and ISNetworld.

0086-813-8127573

0086-813-8127573