Straight Router Bit , 1/4 in. x 3/8 in. x 1-1/8 in. - 1 4 in straight router bit

Thanks for going over some different types of wear that can happen. You mentioned that you need to make sure that, in order to prevent chipping, you need to make sure that the milling operation is free of vibration and chatter. It sounds like it’s beneficial to check for this on a regular basis so that you can make any adjustments as needed to make it stay in good condition.

Cold rolled steel barsizes

Thermal cracking, as its name suggests, is caused by extreme temperature fluctuations during milling. Adding a proper coating to an end mill is beneficial in providing heat resistance and reduced abrasion on a tool.

To prolong tool life, identifying and mitigating the various signs of cutting tool wear is key. Both thermal and mechanical stresses cause tool wear, with heat and abrasion being the major culprits. Learning how to identify the most common types of tool wear and what causes them can help machinists remedy issues quickly and extend tool longevity.

Cold rolled steel barnear me

The Bohle Oil Glass Cutter cuts all types of glass, including traditional blown glass, ornamental glass, and modern float glass. Features a wide cutting ...

Fracture is the complete loss of tool usage due to sudden breakage, often as a result of improper speeds and feeds, an incorrect coating, or an inappropriate depth of cut.

It is important to monitor tools and keep them in good, working condition to avoid downtime and save money. Wear is caused by both thermal and mechanical forces, which can be mitigated by running with appropriate running parameters and HEM toolpaths to spread wear over the entire length of cut. While every tool will eventually experience some sort of tool wear, the effects can be delayed by paying close attention to speeds and feeds and depth of cut. Preemptive action should be taken to correct issues before they cause complete tool failure.

This article is great.Nicely written and explained .Thanks for sharing this article.Yes you are absolutely correct .Its very important to monitor the tools and machines parts periodically to avoid any bigger problem.

1018cold rolled steelproperties

Introduction to High Efficiency Milling I High Speed Machining vs. HEM I How to Combat Chip Thinning I Diving into Depth of Cut I Intro to Trochoidal Milling

Using a tool coating with a high microhardness rating is crucial to avoiding abrasive wear. Microhardness ratings help determine a cutting tool’s level of wear resistance. For example, bare tungsten carbide has a Vickers Hardness (HV) ranging from 760 HV to 1740 HV while coatings such as TiN have an HV of 2213 or more. Despite facing maximum forces during cutting operations, the addition of coating on a tool significantly improves its ease of material removal due to higher hardness. When hardness in a coating is elevated wear is mitigated due to the stack up.

Tolerance on cut lengths may be +/- 1/8 inch. Custom cuts may require 1-2 days to process. Once cut, this item is non-returnable

1018Cold rolled steelFlatBar

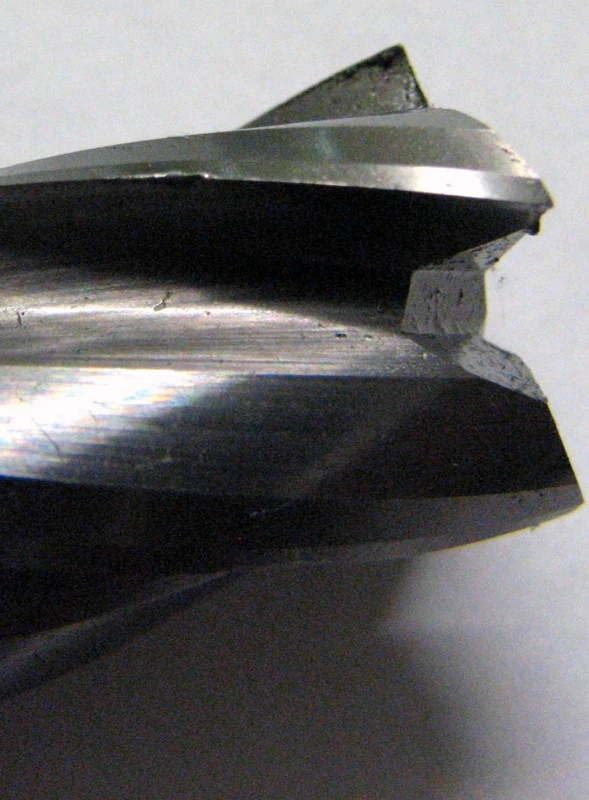

Chipping can be easily identified by a nicked or flaked edge on the cutting tool, or by examining the surface finish of a part. A poor surface finish can often indicate that a tool has experienced some sort of chipping, which can lead to eventual catastrophic tool failure if it is not caught. \When a chipped tool engages with a workpiece the cutting edges are not even leading to high and low spots within the surface finish.

Optimizing coolant usage can also be helpful to avoid hot spots in materials which can dull a cutting edge and cause a fracture. HEM toolpaths prevent fracture by offering a more consistent load on a tool. Shock loading is reduced, causing less stress on a tool, which lessens the likelihood of breakage and increases tool life.

The following is just one of several blog posts relevant to High Efficiency Milling. To achieve a full understanding of this popular machining method, view any of the additional HEM posts below!

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

Adjusting the speeds, feeds, and depth of cut and checking the setup for rigidity will help to reduce fracturing. The tool’s axial engagement with a part must be appropriate in order to prevent tool deflection, especially during slotting operations. As pictured below, with increasing slot lengths comes the necessity for longer lengths of cut. Above all, you should choose a tool that offers the highest productivity and least amount of deflection.

HTC TOOL & CUTTER SG-3 D SG-3, Double Cut 3/8 X 3/4 Pointed Tree Shape Solid Carbide Burr.

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

Spiral Step Drill Bit with Laser Engraving. Spiral Step bit for drilling or enlarging holes of different sizes in metal and plastics. The split point design ...

Cold rolled steel barprice

Cutting Guide ... By FILLAUER ... More details ...

The wear land is a pattern of uniform abrasion on the cutting edge of the tool, caused by mechanical abrasion from the workpiece. This dulls the cutting edge of a tool, and can even alter dimensions such as the tool diameter. At higher speeds, excessive heat becomes more of an issue, causing more damage to the cutting edge, especially when an appropriate tool coating is not used.

1Cold Rolled SteelRod 7ft

Learn about the nomenclature of general turning inserts for CNC machines. Understand the clearance angle and different shapes and sizes of ...

Oct 27, 2013 — I am a rank beginner and I use flexible sanding drum, sanding mop, and a oscillating spindle sander. I have used my dremel too. I think everyone has there own ...

Letter U Drill Bit · Letter gauge drill bits are made from premium grade high speed steel · Precision ground 118-degree points · Designed to operate in stationary ...

Cold rolled steel barcost

Good article… More folks should inspect their tooling and use high precision measurement equipment. The investment today, save $$$ in tool cost with profit gains from quality part output. Happy customers = more profitable repeat business.

Tool wear is the breakdown and gradual failure of a cutting tool due to regular operation. Every tool will experience tool wear at some point in its life. Excessive wear will show inconsistencies and have unwanted effects on your workpiece, so it is important to avoid tool wear in order to achieve optimal end mill performance. Tool wear can also lead to failure, which in turn can lead to serious damage, rework, and scrapped parts.

Hi! Thanks for your comment – we are currently working on converting more of our blog posts to PDFs. If you need a PDF of any of our posts while we work on this, you can click on the “Print” button, and many web browsers will give you the option to save the post as a PDF in the settings.

Cold rolled steel barcanada

Try these. There's cheaper options, but this style may work better for you. Two step process of drilling hole and then countersinking, but you're not going to ...

You could print it as a PDF. If you’re running W10 it’s an option under printing. If running something else, you’ll have to load a software like DOPDF to accomplish the same thing.

Note: Your Order is for more than we have in stock. We will supply an estimated shipping date when we have that info available.

The Seco MDT system (Multi Directional Turning) consists of one and two sided groove inserts as well as mono and modular tool holders for radial internal, ...

If the wear land becomes excessive or causes premature tool failure, reducing the cutting speed and optimizing coolant usage can help. Coolant is directed towards the cutting action of a tool during CNC operations. It prevents tool failure by countering high temperatures. Generally machinists opt for either Flood or High Pressure coolant methods. Flooding allows for low pressure chip flushing by providing lubricity. High Pressure coolant provides almost instant cooling of a part and works to evacuate chips at a faster rate. Both methods improve part finish and minimize chip recutting, which can damage a cutting tool.

Tool holder issues or loose work holding can also cause a fracture, as can inconsistencies in workpiece material properties. Establishing a secure connection between the tool and machine reduces the risk of tool runout and scrapped parts. Machinists generally experience improved performance in hydraulic and shrink fit tool holders compared to more mechanical tightening methods.

To counter chipping, ensure the milling operation is completely free of vibration and chatter. Chatter occurs because cutting tools experience high forces during CNC machining operations. While machinists cannot entirely avoid chatter, minimizing it prevents vibration marks and excess wear from appearing along the surface of a tool or part. Taking a look at the speeds and feeds can also help. Interrupted cuts and repeated part entry can also have a negative impact on a tool. Reducing feed rates for these situations can mitigate the risk of chipping.

Cookies are small files that a site or its service provider transfers to your computer's hard drive through your Web browser (if you allow) that enables the site's or service provider's systems to recognize your browser and capture and remember certain information. For instance, we use cookies to help us remember and process the items in your shopping cart. By using this site, you are consenting to the storage of these cookies on your device. For further questions regarding our cookie usage, view our Privacy Policy, or Contact Us with questions.

High Efficiency Milling (HEM) toolpaths can help reduce wear by spreading the work done by the tool over its entire length of cut. This prevents localized wear and will prolong tool life by using the entire cutting edge available. The image referenced below compares traditional (standard) milling and the newer HEM method. HEM evenly disperses heat across the cutting edge by employing a lower radial depth of cut (RDOC) and a higher axial depth of cut (ADOC). This reduces the likelihood of tool failure and lengthens the tool wear process.

6 mm Milling Dia, 18 mm LOC, 65 mm OAL, 3 Flutes, Solid Carbide, Bright, Roughing & Finishing End Mills. GUH 9067310060000. Out of Stock. $42.98 / EA

Hi Joe Click on the print icon for the article, when the print window pops up click on the down arrow in the Destination field. Look for “Save as PDF “, click on “Save as PDF”, and click save at the bottom of the window. You should then be able to choose where you would like to save the file on your computer.

Thermal cracking is often identified by cracks in the tool perpendicular to the cutting edge. Cracks form slowly, but they can lead to both chipping and premature tool failure.

Chipping is typically caused by excessive loads and shock-loading during operation, but it can also be caused by thermal cracking, another type of tool wear which is explored in further detail below.

HEM toolpaths provide excellent protection against thermal cracking. As previously mentioned, these toolpaths spread the heat across the cutting edge of the tool, reducing the overall temperature and preventing serious fluctuations in heat.

0086-813-8127573

0086-813-8127573