Straight vs. Tapered Countersink Drill Bits? - countersink tapered bit

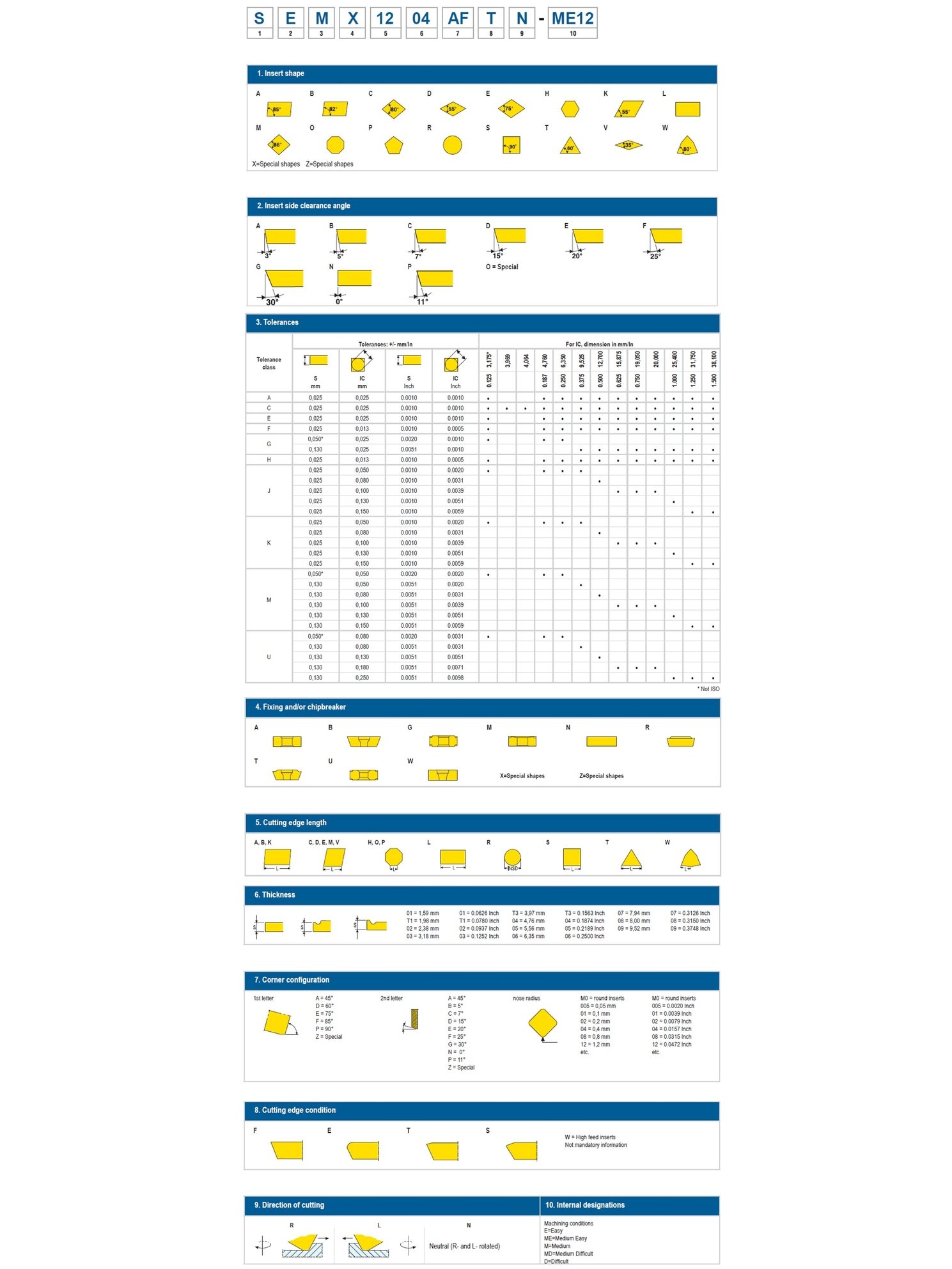

Milling insertspecification

Check out our metal engraving tool selection for the very best in unique or custom, handmade pieces from our tools shops.

Chamfer Mills - Seco chamfer mills offer the same free cutting action as our standard milling cutters, providing strong and reliable performance.

ANSI insert nomenclature

We offer a wide range of drill bits and accessories to maximize your holemaking efforts. Our selection includes jobber drill bits, core drills, circuit board ...

Turn your extended tool life into profit with the incredible KENGold KCP25C Turning Inserts from Kennametal! Special pricing now available on select inserts ...

ISO turninginsert nomenclature

Jul 19, 2021 — Drill bit size chart ... U. 0.368. 9.35. V. 0.377. 9.58. W. 0.386. 9.8. X. 0.397. 10.08. Y. 0.404. 10.26. Z. 0.413. 10.49. Wire Gauge Size Chart ...

Carbideinsert Nomenclature

Findbuytool offers industrial quality 5-piece round over router bit sets with 1/4 inch (6.35mm) shank.

The Craft Batch No. 2 is more than just a beautiful object; it's a performance-driven machine. The precisely milled face delivers a pure roll and exceptional ...

Insert nomenclaturechart

High feed milling is a milling method that permits up to three times faster machining than conventional methods.

... PRODUCT TABLE. Speeds & Feeds · Machining Advisor Pro. SIM Files. CAM LIBRARIES. Reviews. CUSTOMIZE THIS TOOL. Advanced Search. Show. 10, 25, 50, 100. THREAD

Carbideinsertidentification chart PDF

The system is designed so that each important feature and dimension of the insert is shown using a code system. This becomes the name of the insert.

It's important to remember that the ISO designation system is not a system that standardizes the quality of the insert. Neither the carbide grade nor the cutting geometry is standardized in this designation system.

ISOinsert nomenclaturepdf

THE ISO designation system for indexable insertsThe ISO designation system for indexable inserts (ISO 1832) is a standardized system to name an indexable insert.The system is designed so that each important feature and dimension of the insert is shown using a code system. This becomes the name of the insert. This system has several advantages:Unique naming of an indexable insert (supplier independent)All important features and dimensions are clearly stated in the nameSome code positions relate to the insert carrier in which the insert can be mounted It's important to remember that the ISO designation system is not a system that standardizes the quality of the insert. Neither the carbide grade nor the cutting geometry is standardized in this designation system. This is an example for milling inserts. For other applications, you can refer to the relevant Machining Navigator. Do you want to know more?Contact Us Inline Content - SurveyCurrent code - 5fce8e61489f3034e74adc64

Chucking Reamers · Intended for use in drill presses, lathes and screw machines · Most commonly used style for reaming holes to a tight tolerance · Come in ...

0086-813-8127573

0086-813-8127573