Surface Speed (SFM) Calculator - rpm to sfm formula

Coatings increase the hardness of the carbide inserts, making them more resistant to wear. This allows the inserts to withstand the high forces and temperatures generated during cutting operations, resulting in longer tool life and reduced tool replacement frequency.

Carbide insertmaterial codes

Coatings reduce the friction between the carbide inserts and the workpiece, resulting in smoother cutting action. This minimizes heat generation and prevents the build-up of chips on the cutting edge, leading to improved chip evacuation and better surface finish.

Coatings provide thermal stability to the carbide inserts, allowing them to withstand high temperatures without losing their hardness or deforming. This enables higher cutting speeds and feeds, increasing productivity and efficiency.

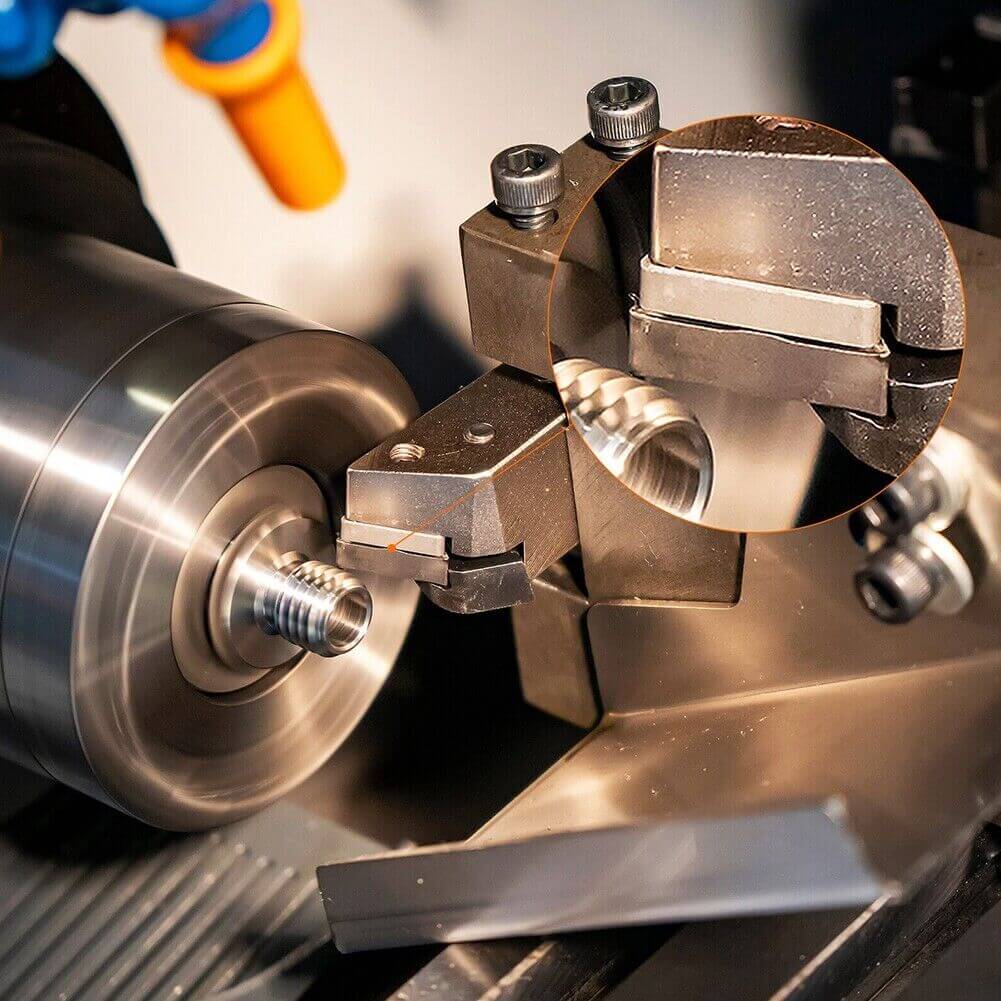

Carbide insertShape chart

Millinginsertspecification

By improving wear resistance, reducing friction, and enhancing heat resistance, coatings significantly extend the tool life of carbide inserts. This reduces the frequency of tool changes, increases production uptime, and lowers tooling costs.

Coated carbide inserts can withstand higher cutting speeds and feed rates due to their increased hardness and reduced friction. This results in faster machining times and higher productivity.

The purpose of coating carbide inserts is to enhance their performance, durability, and cutting capabilities. Coatings provide several benefits that contribute to the overall effectiveness of carbide inserts. Here are the main objectives of coating carbide inserts:

Carbide insertidentification chart PDF

Enhanced Performance in Specific Applications: Different coatings are designed to excel in specific machining applications or materials. For example, some coatings are optimized for high-speed machining, while others are suitable for cutting high-hardness or high-temperature alloys. Coatings can be tailored to specific requirements to achieve optimal performance. Overall, the purpose of coating carbide inserts is to improve their performance, increase their durability, and optimize their cutting capabilities. Coatings enhance wear resistance, reduce friction, improve heat resistance, extend tool life, and enable better performance in various machining applications.

The Magnum Super Premium drills will substantially outperform cobalt drills in work hardening stainless steel applications. This performance advantage is the result of construction differences between the two types of drills. Cobalt drills, manufactured to Type J NAS907 specs, has a very thick web. This web is necessary to limit breakage of the brittle cobalt steel. Magnum Super Premium drills are made of special Hi-moly tool steel, which is much tougher than cobalt steel. The web on a Magnum Super Premium drill can be thinned considerably due to the toughness of the steel.A Magnum Super Premium drill with its thin web will penetrate the work hardening stainless fast enough to continually cut beneath the chip which is hardening from deformation. This means the drill is cutting softer steel. The cobalt drill, with its thick web, cannot be fed at a fast enough rate to cut beneath the area which is hardening. As a result the cobalt drill is continually drilling into hardened steel.

0086-813-8127573

0086-813-8127573