Swiss Chalet / Harvey's - Fast Food Restaurant in Edmonton - harveys west edmonton

I think SoD is getting confused between surface speed and feed rate. When facing ideally one would increase spindle speed to keep surface speed the same as the tool approaches the centre. …

Search for: Home › Forums › Beginners questions › Topics Viewing 25 topics - 1 through 25 (of 25 total) Topic Voices Posts Last Post Sanding Station Started by: Michael Gilligan in: Workshop Tools and Tooling 9 14 10 November 2024 at 23:31 Michael Gilligan Tool room humour 1 2 Started by: Ian Johnson 1 in: The Tea Room 19 28 10 November 2024 at 22:10 Michael Gilligan Horizontal mill cutter runout Started by: Mick Bailey in: Manual machine tools 11 12 10 November 2024 at 22:05 RobCox Horizontal Mill Identification Started by: Mike Freeman in: Workshop Tools and Tooling 3 3 10 November 2024 at 21:21 not done it yet Scroll Saw Blades for Steel Started by: James Alford in: Workshop Tools and Tooling 8 12 10 November 2024 at 17:57 James Alford Tap alignment in the mill and lathe? 1 2 Started by: Bo’sun in: Workshop Tools and Tooling 18 37 10 November 2024 at 17:54 Bo’sun Another One Gone! 1 2 Started by: Chris Crew in: The Tea Room 19 30 10 November 2024 at 14:27 John Haine Spring material advice needed Started by: old mart in: Materials 7 9 9 November 2024 at 21:05 old mart Trapezoidal tap drill size ? Started by: jim1956 in: Beginners questions 5 7 9 November 2024 at 18:47 jim1956 Nominal sizes? Started by: Bo’sun in: Workshop Tools and Tooling 6 8 9 November 2024 at 17:25 Bo’sun Estimated value of restored lathes Started by: harmond94 in: General Questions 9 9 9 November 2024 at 12:33 mgnbuk Anyone interested in sharing a space? Started by: harmond94 in: Help and Assistance! (Offered or Wanted) 1 1 9 November 2024 at 12:27 harmond94 a more unusual hobby shed find 1 2 Started by: pgk pgk in: The Tea Room 22 35 9 November 2024 at 12:17 Vic Myford 4-slot vertical slide & vice Started by: flatline in: Beginners questions 12 21 9 November 2024 at 10:43 Nicholas Farr Provenance Started by: Martin Kyte in: The Tea Room 2 2 9 November 2024 at 09:50 noel shelley Universal Machine Tool Started by: Vic in: The Tea Room 7 11 8 November 2024 at 16:42 Steam of Steel Boll Aero18 Drawings Started by: Clive Brown 1 in: I/C Engines 4 8 8 November 2024 at 15:44 JasonB Shipping deliveries – USA style – video Started by: Bazyle in: The Tea Room 5 6 8 November 2024 at 15:07 old fool Electromagnets (Split From Stuart Dynamo) 1 2 3 Started by: SillyOldDuffer in: Beginners questions 15 70 8 November 2024 at 13:39 duncan webster 1 Alternative to Bronze? Started by: Vic in: Materials 11 14 8 November 2024 at 11:01 peak4 Dull men Started by: old fool in: The Tea Room 7 12 8 November 2024 at 09:39 vic newey Motor Carbon Brushes Started by: David Deaville in: General Questions 8 15 8 November 2024 at 09:37 Howi Stuck Tich piston 1 2 Started by: Mark Salzedo 1 in: Beginners questions 14 37 7 November 2024 at 22:59 Mark Salzedo 1 Which steel for studs? Started by: John McCulla in: Materials 15 24 7 November 2024 at 22:54 noel shelley Another, What is it? Started by: Ian P in: The Tea Room 3 4 7 November 2024 at 20:57 Ian P Viewing 25 topics - 1 through 25 (of 25 total)

I'd agree with Clive that the slower facing feeds are down to the practicalities, and cost, of the mechanism within the apron rather than any cutting considerations. My lathe has selectable feeds from 1 thou per rev to 80 thou per rev, with facing feeds half those. Never had the nerve to use feedrates much more than 20 thou/rev. Even with a 3hp motor and a geared headstock the lathe is power limited on high feed rates with sensible depths of cut.

Yes, but I'm grateful for it on my Warco because powered crossfeed enables fine milling on the vertical slide. The machine would be materially less versatile without it.

The slowest gear on my son's Chester is so slow it doesn't even quote a speed for facing. I assume part of the difference is simply down to the cross slide being on a screw and the carriage on a rack.

Looks to me as if the designer made a list of all the things that seemed wrong to, or just plain irritated, him with "standard" lathes and controls. Then set out to fix them the way he wanted.

The reason that the rack is used for sliding feeds is to preserve the accuracy of the leadscrew for threadcutting. Many of us are familiar with a lathe or mill's screws being locally worn. Apart from small 'amateur' lathes, even lathes produced for training or light engineering purposes had a separate feed bar usually driven from the gear train that drives the leadscrew, or a keyway cut along the leadscrew to serve the same purpose. Clive's point above about doing it right, I take it to mean using current technologies of recirculating ball leadscrews or other methods causing less wear of the leadscrew.

Maybe someone could build a motorised lathe designed to face closer to constant cutting speed by accelerating the tool-post as it moves to the centre. I can think of lots of problems with the idea! As my lathe faces well with ordinary methods, gut feel suggests fine tuning facing speeds is more trouble than it's worth. Good enough is good enough. No facing disasters on my long list of miserable workshop failures!

I think you would want to accelerate the lathe spindle speed rather than the feed to keep the surface speed the same with the same (constant) depth of cut set by the gearbox. I think that would be equally worrying to the operator!

Personally, I don't mind too much as I'm pretty sure I would break something if I tried to part off at the same rate as plain turning.

It almost breaks my heart to imagine what it might have cost new, and after a google-search to see the second-hand prices at the end of its life.

Wot? I use the same feed rates for sliding and surfacing cuts (changing the feed gearbox) and I don't get crappier finishes on facing. With the caveat that sometimes the finish deteriorates at the centre. But that's down to material and surface speed issues, not feedrate. It's rare that I need to face an item right to the centre. Normally there's a centre hole so I'm not worried about the last little bit.

Even hobby machines, with Norton boxes, such as the Warco BH600, BH900, Chester Craftsman, and Engineers ToolRoom BL12-24 do this. There is a lever to engage either the Feed shaft or the Leadscrew, so the Leadscrew is spared the wear resulting from providing the sliding feed..

The only industrial standard lathe I can immediately think of that uses the feed screw rather than the rack for sliding feeds is the Ikegai **LINK** . But that has a ballscrew and a fair few other features suggesting the designer was unimpressed with much of standard lathe design practice and metaphorically speaking said "Stuff it. I'm gonna do it right." Leaving aside the practicalities of weight, size and power supply I think I'd rather like one.

Define depth of cutin lathe machine

Many lathes use a separate feed shaft to power both sliding and facing feeds, with the sliding feed via the rack. Certainly most Industrial quality lathes do this.

Feedrate formula

The Ikegai has a lot of fascinating detail, and not so detail, differences in design and construction when compared to the usual modern lathe like the Colchester 2000 et al.

I don't understand why there is a factor of (roughly) five between the two ranges. Is it perhaps a 'feature' of these lathes resulting from economies in the design of the apron gearbox? Or is there an 'engineering' reason why surfacing feed should be so much slower than sliding feed?

Clive I have never come across a lathe with the sliding feed generated by the rack. Surely it's what the leadscrew is for.

Oh poo, Andrew is right! But as spindle speed and feed rate are geared together on most lathes my point about cutting speed still stands. I hope…

Some machines have sliding feed and cross feed directions reversed so when the sliding feed is towards the chuck the cross feed is away from the work. Something that I found seriously annoying on my Southbend Heavy 10. But if the lathe only has a single clutch for both feeds it is a safety feature should the user inadvertently engage the wrong feed during a job. My Smart & Brown 1024 only has a single clutch but bothe feeds are in the same direction and I have been known to forget which is selected. Ooops!

My Warco faces at about 40% of the turning rate, I just flick the 3-way speed selector into the next position when facing and get the two speeds approx the same without having to play with the gears.

What is feed in lathe machineused for

My lathe (a generic Far Eastern 12×36) has surfacing (X-axis) and sliding (Z-axis) power feeds. According to the plate on the headstock the gearbox allows a range of surfacing speeds from 0.011 to 0.276 mm/rev and sliding feeds from 0.053 to 1.291 mm/rev.

Worth nooging around on the http://www.lathes.co website to see typical apron and power drive internals to get a feel for why things are done that way.

It does on my lathe – Harrison M300. The leadscrew doesn't even turn with feeds selected. The leadscrew only runs when thread pitches are selected. But of course my lathe is industrial with a separate feed shaft running parallel to the leadscrew.

Clive, looking at lathes.co.uk, the Ikegai A-20 (for example) has some very nice features and seemed to incorporate these quite early on, including the recirculating ball leadscrew. But then it is described as a toolroom lathe.

Just about all lathes with a feeds / screwcutting gearbox use the rack to drive sliding feeds via a worm drive and keyway pick off from a feed drive shaft. Sometimes, on lighter machines, the feed drive shaft and threading feed screw are combined by cutting a keyway in the screw. The SouthBend and its clones being a common example.

What is feedrate

Lathespeeds and feeds calculator

Unless the cost cutters have got to them, most of their Geared Head offspring seem to have the same professional features.

Cutting speed is an important parameter. Turning a rod lengthways, it's easy to set a constant speed optimised for material and cutter. However, the lathe needs to cater for slow metals like cast-iron and mild-steel, medium speed free-cutting steels & bronze, and fast cutting metals like Brass and Aluminium. Ideally it should allow carbide to cut about 5 times faster than HSS as well. Having plenty of choice of lengthways cutting speed is a 'good thing', and most machines provide it.

Don't think it is an engineering thing. The Smart and Brown Model M has sliding speed is pitch/16 and surfacing is pitch/32 so different but only a factor of 2 from one to the other.

![]()

Facing is a different problem because cutting speed changes radically as the tool moves towards the centre. At the outer edge the work whizzes past the cutting point, but cutting speed drops towards zero as the tool moves to the centre point. I guess a lathe's base facing feed rate is chosen to suit the maximum outer diameter it can face. After that, not much point in fretting because the cutting speed inevitably drops at the cutter moves in. Good enough results with a simple gear box. Same gear box deals with parting off, which calls for steady rigidity rather than perfect speed control.

Define cutting speedin lathe machine

A less satisfactory compromise on many Chinese machines is minimum rpm. Often screw-cutting under power on these machines is much too fast for comfort! Electronic speed control is great for most purposes, but my dear old mini-lathe definitely needed back-gear. My WM280 with 3-phase motor and VFD is much better managing well enough at 30 rpm, but it's far happier cutting threads in reverse away from the headstock 2 to 5 times faster. Although a WM-280 is 'good enough', having back-gear as well would help on the few occasion's I need lots of turning power at slow speeds. But back-gear is a costly addition and an obvious economy when it's only rarely needed.

Who wouldn't want a finer feed on the surfacing? Do you want a crappy finish for some reason? The causer feeds are normally only there by accident of the screwcutting gearbox giving the range and marketing put it in the spec to make it seem like there is something extra. It's like the screwcutting range specified – when did you last screwcut 128tpi but hey your lathe does 40 imperial threads so must be better than the one with only 20 quoted.

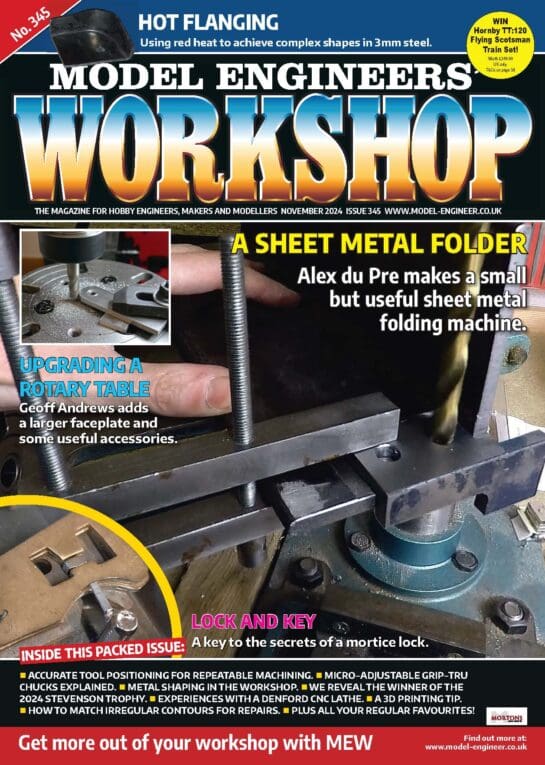

Model Engineer and Model Engineers' Workshop are leading magazines for modellers, with reputations for bringing you the best tips, tricks, and inspiration from the model engineering world. From miniature steam locomotives to clocks and tools, get the most out of your hobby with Model Engineer and Model Engineer's Workshop.

What is feed inmachining

The point is he has a 1.2mm/rev sliding feed so to avoid a striated finish tools have to have a wide radius or long flat whereas the surfacing feed is much less to a better finish will be achieved if a pointed tool is being used. yes, you know to put a flat on the tool but a lot of beginners don't.

Sanding Station Tool room humour Horizontal mill cutter runout Horizontal Mill Identification Scroll Saw Blades for Steel Tap alignment in the mill and lathe? Another One Gone! Spring material advice needed Trapezoidal tap drill size ? Nominal sizes?

Generally with a mostly common gear train inside the apron. The sliding feed is generated via the rack on the bed and the cross feed via the feed screw. Rack pitch is always coarser than the feed screw so sliding feed will be greater unless the designer opts for more or less completely separate drives. Which adds much complexity for little benefit as the slower surfacing feed works fine when used appropriately.

What is feed in lathe machineformula

I think SoD is getting confused between surface speed and feed rate. When facing ideally one would increase spindle speed to keep surface speed the same as the tool approaches the centre. Indeed on some materials with insert tooling one can see the surface finish change (gets worse) as the tool moves to the centre. On CNC lathes it's easy to use constant surface speed (CSS) when facing, via the G96 code. But the feedrate in terms of distance per rev stays constant. To a large extent surface speed and feedrate requirements are independent of each other on a lathe. Not so on a mill – there it's chip load rather than feed that stays constant with spindle speed.

Home › Forums › Beginners questions › Questions about lathe power feeds. This topic has 48 replies, 22 voices, and was last updated 13 June 2020 at 22:30 by Robin Graham. Viewing 25 posts - 1 through 25 (of 49 total) 1 2 → Author Posts 5 June 2020 at 21:32 #10281 Robin GrahamParticipant @robingraham42208 Advert 5 June 2020 at 21:32 #477790 Robin GrahamParticipant @robingraham42208 My lathe (a generic Far Eastern 12×36) has surfacing (X-axis) and sliding (Z-axis) power feeds. According to the plate on the headstock the gearbox allows a range of surfacing speeds from 0.011 to 0.276 mm/rev and sliding feeds from 0.053 to 1.291 mm/rev. I don't understand why there is a factor of (roughly) five between the two ranges. Is it perhaps a 'feature' of these lathes resulting from economies in the design of the apron gearbox? Or is there an 'engineering' reason why surfacing feed should be so much slower than sliding feed? If anyone can shed light I'd be grateful. Robin. Edited By Robin Graham on 05/06/2020 21:52:53 5 June 2020 at 21:45 #477793 John HaineParticipant @johnhaine32865 Economy of design, I'd guess. 5 June 2020 at 22:03 #477796 Brian GParticipant @briang The slowest gear on my son's Chester is so slow it doesn't even quote a speed for facing. I assume part of the difference is simply down to the cross slide being on a screw and the carriage on a rack. Personally, I don't mind too much as I'm pretty sure I would break something if I tried to part off at the same rate as plain turning. Brian G 5 June 2020 at 22:17 #477800 Anonymous On my lathe (M300) the cross feed is half the selected sliding feed. I suspect it's to do with the space available for convenient size gears in the apron. Andrew 5 June 2020 at 22:22 #477803 Martin ConnellyParticipant @martinconnelly55370 Don't think it is an engineering thing. The Smart and Brown Model M has sliding speed is pitch/16 and surfacing is pitch/32 so different but only a factor of 2 from one to the other. Martin C 6 June 2020 at 06:57 #477833 JasonBModerator @jasonb My Warco faces at about 40% of the turning rate, I just flick the 3-way speed selector into the next position when facing and get the two speeds approx the same without having to play with the gears. 6 June 2020 at 09:50 #477863 SillyOldDufferModerator @sillyoldduffer Good old engineering compromise I reckon. Cutting speed is an important parameter. Turning a rod lengthways, it's easy to set a constant speed optimised for material and cutter. However, the lathe needs to cater for slow metals like cast-iron and mild-steel, medium speed free-cutting steels & bronze, and fast cutting metals like Brass and Aluminium. Ideally it should allow carbide to cut about 5 times faster than HSS as well. Having plenty of choice of lengthways cutting speed is a 'good thing', and most machines provide it. Facing is a different problem because cutting speed changes radically as the tool moves towards the centre. At the outer edge the work whizzes past the cutting point, but cutting speed drops towards zero as the tool moves to the centre point. I guess a lathe's base facing feed rate is chosen to suit the maximum outer diameter it can face. After that, not much point in fretting because the cutting speed inevitably drops at the cutter moves in. Good enough results with a simple gear box. Same gear box deals with parting off, which calls for steady rigidity rather than perfect speed control. Maybe someone could build a motorised lathe designed to face closer to constant cutting speed by accelerating the tool-post as it moves to the centre. I can think of lots of problems with the idea! As my lathe faces well with ordinary methods, gut feel suggests fine tuning facing speeds is more trouble than it's worth. Good enough is good enough. No facing disasters on my long list of miserable workshop failures! A less satisfactory compromise on many Chinese machines is minimum rpm. Often screw-cutting under power on these machines is much too fast for comfort! Electronic speed control is great for most purposes, but my dear old mini-lathe definitely needed back-gear. My WM280 with 3-phase motor and VFD is much better managing well enough at 30 rpm, but it's far happier cutting threads in reverse away from the headstock 2 to 5 times faster. Although a WM-280 is 'good enough', having back-gear as well would help on the few occasion's I need lots of turning power at slow speeds. But back-gear is a costly addition and an obvious economy when it's only rarely needed. Dave 6 June 2020 at 10:35 #477879 Clive FosterParticipant @clivefoster55965 Its normal practice to have the facing feed slower than the sliding feed. Generally with a mostly common gear train inside the apron. The sliding feed is generated via the rack on the bed and the cross feed via the feed screw. Rack pitch is always coarser than the feed screw so sliding feed will be greater unless the designer opts for more or less completely separate drives. Which adds much complexity for little benefit as the slower surfacing feed works fine when used appropriately. Worth nooging around on the http://www.lathes.co website to see typical apron and power drive internals to get a feel for why things are done that way. Some machines have sliding feed and cross feed directions reversed so when the sliding feed is towards the chuck the cross feed is away from the work. Something that I found seriously annoying on my Southbend Heavy 10. But if the lathe only has a single clutch for both feeds it is a safety feature should the user inadvertently engage the wrong feed during a job. My Smart & Brown 1024 only has a single clutch but bothe feeds are in the same direction and I have been known to forget which is selected. Ooops! Clive

On my lathe (M300) the cross feed is half the selected sliding feed. I suspect it's to do with the space available for convenient size gears in the apron.

0086-813-8127573

0086-813-8127573