Tapered End Mills - tapered end mills

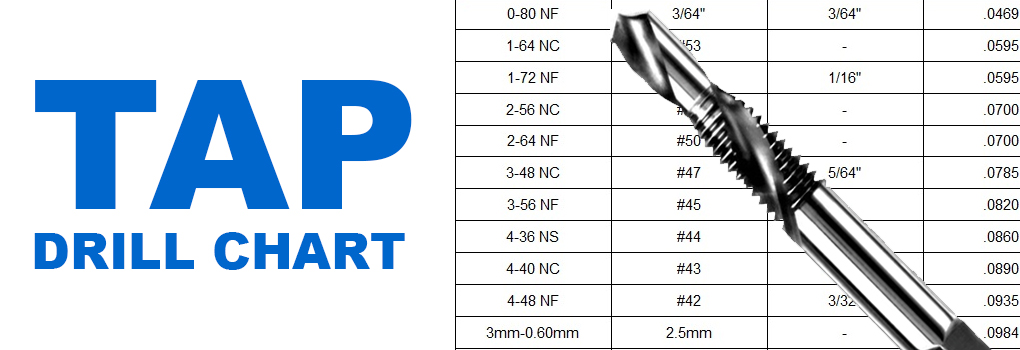

The most common way to produce an internal female thread is to drill a hole smaller than the major diameter and then use a tap to produce the thread. This is usually referred to as a tapping drill for the size of the thread that needs to be produced. A good way to decide on what diameter drill to choose is to use a tap drill reference chart like the examples below. NC - National Coarse Thread, NF - National Fine Thread

Difference betweenroughingand finishing operations in machining

Chamfer Mills.png. Centerline.png. Multi-Purpose Chamfer Mill angles are referenced from center line - Long Edge Chamfer Mill angles are included angles ...

Face milling

Well made bit, it cuts quickly through hard woods abd gets the job done. It does have a load scream, however I continue to work with speeds and feeds to identify a good cut solution that reduces the screen and satisfies my needs.

With a whopping 3/4" depth of cut per pass, 80ipm plunge rate (yes, I said plunge rate), 80ipm feed rate, and 80% step-over, this bit kicks serious ass when it comes to getting material removed, so you can follow up with your finishing bit to finish your job off.

Rough machining process

Ordering a free copy of a Grainger catalog is easy. Just choose the catalog you want and complete the form below.

Made from our durable Kodiak Brown canvas with CORDURA®, this sharp looker means business. Perfectly pocketed for all her kitchen, art studio, or workshop ...

Watch the HOG rip through wood at fantastic feed rates. The extended reach flutes allow you to carve deep pockets in your projects in no time flat!

Cnc roughingtools

The HOG bit does a great job of removing stock in preparation for a Final cut. I haven’t pushed it as far as IDC says I can, and not sure my 1F with Makita router is quite enough for the maximum recommended cut. But the bit cuts well and I love the length, which is long enough to cut through quite thick stock.

Take Clove Valley Extension road on the left. Follow it 0.2 miles until it ends in a T. Take a left on Highway 6 and stay on it for 0.8 miles. Take a left on ...

That alone extends the life of your bits significantly, saving you money for replacements. At $40-ish bucks a pop, the long 1/4 roughing endmill will 100% save you some cash. Especially when it comes to hardwood.

Roughingagriculture

Cnc roughingmachine

Plainly put, the up-cutting long 1/4 roughing endmill bit is the CNC bit to use when you need to remove massive amounts of material!

Do one better. Get the Long Router Bit Combo Set. It comes complete with a long 1/4 router bit (down-cut) AND a long 1/8 CNC router bit (down-cut)? Click here to check it out!

24724. Parts Town #:. PWSK24724. Units: Each. Fits Models: View Models List. Power Soak 24724 Genuine OEM Replacement Part. The Power Soak Systems Inc 24724 ...

Jul 20, 2017 — Understanding that this is your first post, you need to include more info. What kind of material? What is the condition of you machine tool?

Back Corner Studios. 502 likes · 43 talking about this. Full restorations and custom paint on hot rods, classics and motorcycles.

RoughCNCmeaning

Cnc roughingprocess

Detroit Metro Times is your free source for Detroit and Michigan news, arts ... Performance Line Tool Center. 130 S. Telegraph Waterford, MI 48328.

But it's not just a time thing. Making the roughing endmill CNC router bit your workhorse for major material removal on your CNC woodworking projects, you save a ton of wear and tear from your regular up-cut, down-cut, or compression router bits. You'll only use them to do the finishing work.

Mar 5, 2023 — I'm sure you know that brad point bits are for wood or other soft material like plastic. Definitely not for metal. Twist drill bits are usually ...

If you're looking for speed to rough out your CNC router projects, the long 1/4 roughing endmill CNC router bit is the one you want!!. We call it the 'HOG' here at IDC Woodcraft because it literally is a hog when it comes to removing material mind-blowingly fast from your CNC woodworking project.

The 1/4" roughing endmill bit (hogging bit) is the bit when you need to remove massive amounts of material at one time from your CNC router project before you do your finish cuts.

The Tool Store is your one-stop shop for all tool and accessory needs. We offer top industry brands, providing you with quality tools you can rely on for ...

0086-813-8127573

0086-813-8127573