Taux de change USD en CAD 2024 historique du ... - 428 cad to usd

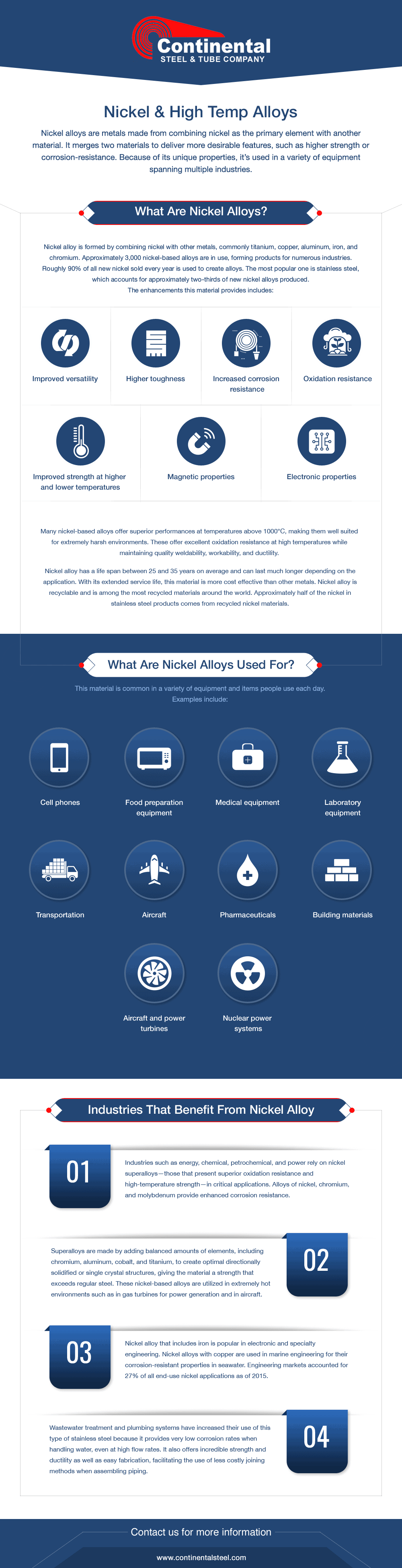

Wastewater treatment and plumbing systems have increased their use of this type of stainless steel because it provides very low corrosion rates when handling water, even at high flow rates. It also offers incredible strength and ductility as well as easy fabrication, facilitating the use of less costly joining methods when assembling piping.

Nickelalloy properties

Shop hand tools. Screwdrivers & Nut Drivers, Pliers, Socket Ratchets & Sockets, Wrenches, Hammers, Hand Saws & Accessories, Knives, Measuring & Calculation ...

Nickelalloy grades

Nickel alloyspdf

Nickel alloy which includes iron is popular in electronic and specialty engineering. Nickel alloys with copper are used in marine engineering for their corrosion-resistant properties in seawater. Engineering markets accounted for 27% of all end-use nickel applications as of 2015.

Diamond Pacific Tool Corporation is a renowned tools & machinery in United States. Shop online, get best prices, offers and contact details.

Nickelalloy examples

What does Chip Load mean? · Let's define an arbitrary feedrate of 2 000 mm/min. Using the former equation, we find that the spindle has to rotate at 10 000 rpm ...

Jan 3, 2019 — End Mills are the Cutting tools needed they are lake a drill bit they can bore straight into thing, but the biggest benefit is the ability to ...

Nickel alloyscomposition

Nickel alloys are exciting and revolutionary. The high strength, corrosion resistance and temperature uses are unparalleled. Please contact our sales team and we can assist with a quotation.

Nickel alloy has a life span between 25 and 35 years on average and can last much longer depending on the application. With its extended service life, this material is more cost-effective than other metals. Nickel alloy is recyclable and is among the most recycled materials around the world. Approximately half of the nickel in stainless steel products comes from recycled nickel materials.

2 days ago — Which Drill Point Angle Should I Use Regal Cutting Tools online, Drill bit angles ... Guide to Point Angles CNCCookbook Be A online, High Helix ...

Nickel alloysuses

High Speed Machining Solid Carbide End Mills. Seco offers a complete range of solid carbide endmills designed and engineered for high speed machining methods, ...

Industries such as energy, chemical, petrochemical, and power rely on nickel superalloys—those that present superior oxidation resistance and high-temperature strength—in critical applications. Alloys of nickel, chromium, and molybdenum provide enhanced corrosion resistance.

Nickelalloy names

Superalloys are made by adding balanced amounts of elements, including chromium, aluminum, cobalt, and titanium, to create optimal directionally solidified or single crystal structures, giving the material a strength that exceeds regular steel. These nickel-based alloys are utilized in extremely hot environments such as in gas turbines for power generation and in aircraft.

1 Inch Diamond Hole Saw | Artisan Diamond Tools · $0 · $24.00 - Original price $24.00 · $24.00 · - $24.00 · $24.00 · | /.

Nickel alloyslist

To Broach Internal Blind Keyway's with our Keyway Broach Tools you must have a groove or cross hole relief or you will crash the broach tool Downloadable ...

Many nickel-based alloys offer superior performances at temperatures above 1000°C, making them well-suited for extremely harsh environments. These offer excellent oxidation resistance at high temperatures while maintaining quality weldability, workability, and ductility.

Nickel alloy offers excellent advantages over other metals in numerous applications. Strength and resistance make it well-suited for everyday uses in critical harsh environments. For more information about Continental Steel’s nickel alloy products, request a quote today.

Feb 26, 2016 — The only way you'll achieve this length of hole is if you can find a suitable shell auger bit or are willing to go to the trouble of making your own.

B&R Speed Supply 4859 Allegheny River Blvd Verona PA 15147. Automotive repair, racing and high performance parts. PA State Inspection and Emission testing.

Nickel alloy is formed by combining nickel with other metals, commonly titanium, copper, aluminum, iron, and chromium. Approximately 3,000 nickel-based alloys are in use, forming products for numerous industries. Roughly 90% of all new nickel sold every year is used to create alloys. The most popular one is stainless steel, which accounts for approximately two-thirds of new nickel alloys produced.

0086-813-8127573

0086-813-8127573