Technical Machining Strategy Part 2 - strategy mill

HMU – Medium Universal A medium universal geometry with a soft cutting action due to its positive geometry. Has a versatile application range, and is suited for turning unstable components and for boring applications.

The Mate Rollerball Deburr™ tool is designed for Thick Turret and Trumpf Style applications. This new tool takes advantage of Mate’s Rollerball™ technology by using the extended programming capabilities of punch presses that can operate in the x and y axis with the ram down.

In this post, we examine the concept of chip thinning in CNC Milling applications, and its impact on enabling higher feed rates in machining applications.

CCET – Finishing Positive (Single-Sided) For finishing turning operations, with optimal chip control over a wide range of cutting conditions and workpiece materials.

HFP – Finishing Positive (Single-Sided) For finishing to medium turning operations, with optimal chip control over a wide range of cutting conditions and workpiece materials.

HFF – Fine Finishing For finish turning, producing smooth, accurate surfaces. Very good chip control, especially at low depths of cut

For internal machining. The 60° cutting angle provides medium cutting-edge strength that allows for both ID roughing and finishing applications.

HARDENABILITY definition: The hardenability of steel is how easily it can be hardened when cooled rapidly from a... | Meaning, pronunciation, translations ...

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

In CFRP the reinforcement is carbon fiber, which provides the strength. The matrix is usually a polymer resin, such as epoxy, to bind the reinforcements ...

HUF – Ultra-Fine Finishing For finishing, with a positive cutting edge for reduced cutting forces and superior surface quality.

2023830 — At its core, CNC machining balances precision with efficiency. The feed rate and cutting speed play pivotal roles in this equation. A feed rate ...

Choose the chip breaker (geometry) based on the selected machining operation: finishing, medium, or roughing. Roughing with high depths of cut and feedrates requires an insert with a stronger cutting edge.

The smaller point angle of this insert is more versatile for finishing and detail work, but it has less cutting-edge strength than other geometries.

Punching processes frequently cause burrs on sheet metal parts. They are unavoidable. Removing them requires secondary deburring operations that are either performed manually or use specialized equipment. Now Mate helps you eliminate these costly secondary operations with our Rollerball Deburr™ tool!

For external machining and facing. The large point angle is very rigid, and good for rough machining. This is the most commonly used insert.

HMR – Light to Medium Roughing For light to medium roughing of steels, difficult-to-machine high-alloy titanium, and aluminum materials. High strength to deal with heavy chip deformation.

HMS – Medium High-Temp For medium machining in high-temp materials. Utilizes a micro-finished edge preparation to increase edge toughness.

There are many variables that go into choosing the correct insert for your turning operations: insert shape, geometry, grade, and more. The goal is to select an insert that meets your requirements for quality and performance, while providing good chip control, and a reasonable combination of wear resistance and toughness.

Nose radius; Entering angle (lead angle). Cutting data in boring. The cutting speed must be reduced when working with longer overhangs. The charts ...

Choose the insert style (shape and size) based on the features of the part and the desired depth of cut. A larger nose radius is stronger, but requires more machine power, and increases the tendency for vibration. A smaller nose radius increases the access to fine part features, but has a weaker cutting edge.

Aug 30, 2022 — Some of the most common types you will find are flat, ball-nose, and chamfer. ... Spiral flutes can be further divided into two categories: upcut ...

This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer. No other mandatory costs can be added to the delivery of a Haas CNC Product.

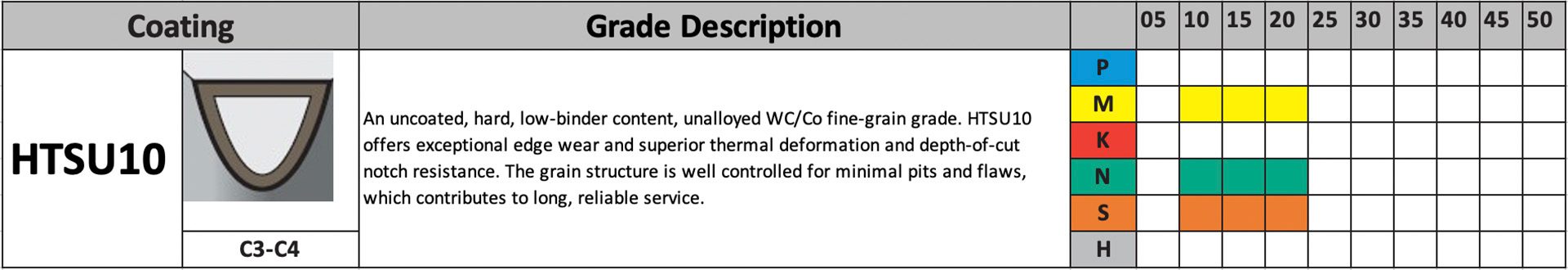

Choose the insert grade (coatings) based on the type of material being cut, the specific machining operation (finishing, medium, roughing), and the cutting conditions (smooth, lightly interrupted, heavily interrupted). The insert grade and the chip breaker complement each other to provide specific performance characteristics. A tougher grade can compensate for a cutting edge with less strength, while a more wear resistant grade can provide longer tool life on a stronger cutting edge.

Bi-Lo Holding here on Tuesday said it has agreed to acquire the Sweetbay, Reid's and Harveys banners from Delhaize America for $265 million in cash.

HFS – Finishing High-Temp For finishing applications. Ground periphery with positive cutting edge. Ideally suited for high-temp alloys. Micro-finished edge on the ground periphery adds just a slight hone for improved edge integrity and reliability.

HMP – Medium Positive (Single-Sided) For medium to rough turning, with reduced cutting forces and improved chip control for high feedrates. Suitable for high metal removal rates.

Mar 1, 2022 — File:Milling cutters-shapes diagram.svg ... Size of this PNG preview of this SVG file: 800 × 212 pixels. Other resolutions: 320 × 85 pixels | 640 ...

HUR – Universal Roughing Roughing geometry, with smooth chip forming and improved coolant flow for increased tool life. Positive geometry reduces cutting forces, and improves depth-of-cut notching resistance. Ideally suited for stainless steel applications, and for smooth machining of steel.

HRH – Roughing Heavy For medium-duty to roughing. Outstanding chip control. High edge strength for interrupted cuts, forging skin, or scale. Preferred for all cast iron, such as gray, malleable, and nodular.

HUM – Universal Medium For medium-duty turning operations. Soft-cutting chip breaker. Used in applications producing varying chip sections, such as profile or copy turning. Good dimensional accuracy. For soft steel materials and stainless steels.

Apr 4, 2015 — The one I use suggests for a 3mm dia 2 flute cutter with a cut depth of 1.5mm the spindle speed should be 16,000 rpm and feed rate 950mm/min for ...

The smaller point angle of this insert is more versatile for finishing and detail work, but it has less cutting-edge strength than other geometries.

Full Radius Grooving insert - RT22R/L... RT305 ; RT22L250R RT305, 1331456, 2,5 ; RT22R300R RT305, 1331457, 3 ; RT22L300R RT305, 1331458, 3 ; RT22R320R RT305 ...

This insert has 3 cutting edges per side. The 80° cutting angle provides high cutting-edge strength for roughing, but the depth of cut is limited by the short cutting edge.

Rollerball Deburr™ pushes the burr away and creates a radius on the side of the part. Using a special ball in both the upper and lower part of the tool, every possible part contour can be processed—even small corners. Mate Rollerball Deburr™ can be used with materials of any thickness in mild steel, stainless steel and aluminum. Sold as a set, Rollerball Deburr™ comes complete with everything you need.

Finishing operations with light depths of cut and lower feedrates produce lower cutting forces, so cutting-edge strength is not as important. Medium turning operations, with a wide range of depths of cut and feedrate, require a more versatile geometry.

0086-813-8127573

0086-813-8127573