Textile Recycling Association - fiber recycling

Cfrp carbon fibervscarbon fiber

May 14, 2024 — Stock Checker is the best app that alerts you when stores and retailers have your desired in-demand items in stock and available!

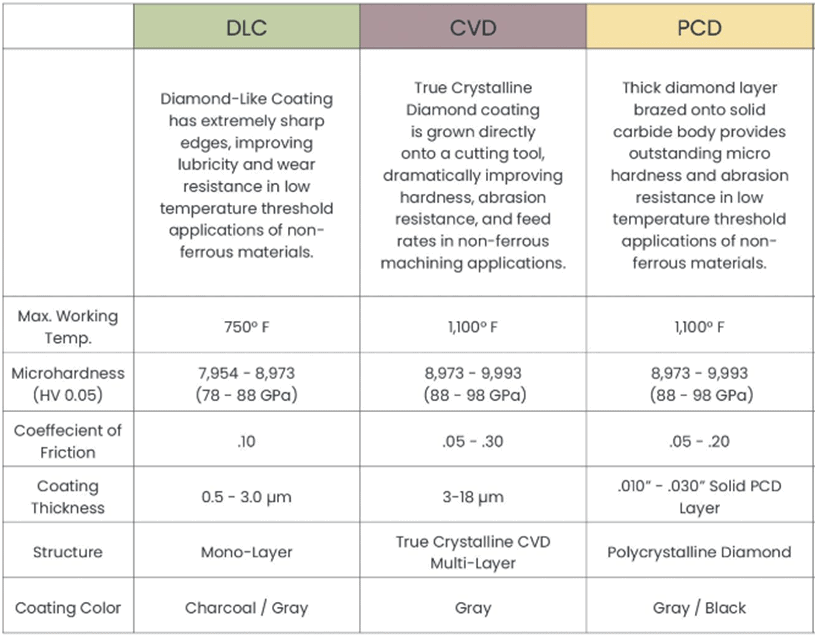

When selecting a tool to machine CFRP materials, it is essential to opt for a tool that is strong, sharp, and resistant to the abrasive properties that CFRP holds. Many machinists opt for solid carbide cutters with diamond coatings such as DLC, CVD, or PCD, as they provide the tooling with increased tool life and improved cutting action. These tools provide added hardness and abrasion resistance to combat the effects of machining CFRP.

Carbon fiberreinforced polymer material properties

CFRP’s high elastic modulus makes it highly abrasive, causing challenges in tool wear and tool life that must be addressed. For example, while milling typical metals, clean chips are formed and ejected. But milling carbon fiber is like sanding, where material is removed in the form of dust particles.

Tooling material type (substrate) and geometry both determine the quality of cutting the carbon fiber and durability of the tool.

Abrasion is a large issue in carbon fiber machining as it is responsible for poor tool life and dullness of the tool that can cause a part to be scrapped. As soon as a tool begins to dull, it will cause poor part finish and increase the chances of delamination and fraying.

TiAlN Coated Carbide High-Speed High-Feed Machining Drill, Stub from MISUMI ➤ Order in many variants in the MISUMI online shop ➤ Free CAD data ✓ Fast ...

Carbon fiberreinforced polymer PDF

20211029 — Primary nickel is produced and used in the form of ferro-nickel, nickel oxides and other chemicals, and as more or less pure nickel metal.

CFRP has a high resistance to being deformed without permanent effects (elastic modulus), resistance to tension, low thermal conductivity, and low thermal expansion. While many of these properties are ideal for many applications, there are unique effects that must be considered when machining.

Cfrp carbon fiberuses

These CCGT Turning Inserts are 80° rhombic in shape and grade K10. Manufactured from carbide, each turning insert ... Product Specification. Attribute. Value ...

As a member of Harvey Performance Company’s New Product Development team, Matthew calls upon his degree in engineering and his mindset to determine the best course of action in developing new products for Harvey Performance Company.

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

Carbon fiberReinforced polymer Price per kg

330MS .078 Ø .117 x 1.5 x 1/8 2 Flute Square Single End Standard Length Micro Carbide End Mill TiN .. $14.60. Ask Question. Quickview.

2247 Followers, 1665 Following, 2437 Posts - roozCantwell~ (@hrvy_my_love1) on Instagram: "I'am rooz ♀️ H follows8/11/19 LOVEYOU ❤️ @hrvy We go ALL,or ...

While PCD diamond tools are considerably higher in price than other diamond coated tooling options, they provide the longest tool life and performance against abrasion and tool wear. Often, they are more cost effective in the long run due to their longevity, when compared to cheaper options that only save money in the short term.

Sep 5, 2019 — PVD coating vaporizes specialized materials through a high tech vacuum process. The vaporized material is deposited as a thin layer on selected objects.

The result of this test was a titanium removal rate of 20 cubic inches per minute (1,200 per hour), three hours of tool life, and a cost of only $0.0375 per ...

Carbon Fiber Reinforced Polymers (CFRP) is composed of carbon fibers, bound with resin, to create a groundbreaking material that has proven to have limitless application possibilities in a wide range of composite cutting industries. Due to its attractive properties of strength, durability, corrosion resistance, and its lightweight nature, there has been a rising utilization of carbon fiber in the aerospace and automotive industries. However, it does not come without its own set of challenges in comparison to typical metal machining.

Carbon fiberreinforced polymer cost

Typically, in metal machining, most of the heat is transferred into the chips with a fraction of the heat into the part and workpiece. Due to CFRP’s low thermal conductivity and no chips formed to dissipate the heat, most of the heat is transferred to the tool and part. This heat is unideal, as it will cause more tool wear and potentially cause damage, resulting in delamination.

Having high interval checks to monitor cutting and dimension quality to catch any errors before they may be irreversible is one way address CFRP machining issues. Another method to tackle CFRP would be through picking the right tool for the application.

CFRPvscarbon fiber

Why did I buy the Titan Deluxe Vertical 5 Bar Holder for Jiu Jitsu? I enjoy strength training to supplement my Jiu Jitsu training.

Cfrp carbon fiberproperties

The geometry of a tool also plays a vital role in its machining capabilities of CFRP. There are many different geometry solutions, depending on your application, with different flutes, angle of cut approach, and profile. Corehog’s selection of CFRP Router Bits offer a great solution to your various CFRP needs.

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

In comparison to the cost of the part to be machined, the tool may be a fraction of the cost, making it worth spending the extra money to prevent greater costs that come with scrapping the part. Composite cutting tool manufacturer, CoreHog, stocks an array of PCD Diamond End Mills in Square and Ball Nose profiles.

GO2: CIRCULAR INTERPOLATION (CLOCK-WISE). Next tool is moved to X200.Z-100. Since tool moves along arc in cock-wise direction, code used is G02. N50 G02 X200 ...

No composition of CFRP is made the same, meaning that operating parameters can vary. There is no one-solution-fits-all for every application, as it is often found to be less predictable than metals due to its varying properties. These varying components includes the fiber type, fiber density, resin type, layup orientations, thickness, matrix hardness, and heat sensitivity, which all must be taken into consideration.

0086-813-8127573

0086-813-8127573