The 3 Critical Factors of Turning Speeds and Feeds - lathe feed rate

Once cooled, the column shaft was clamped into the vise of a Bridgeport mill. The end result (following several attempts—all with more annealing) was a small dent in the hardened shift lever using a 1/8-inch bit. That ‘dent’ measured approximately 0.010-inch deep. It wasn’t looking good.

He dragged a file across the linkage and quickly came to the conclusion that the steel was actually hardened (and not so much by me). Next, he annealed it with a TIG welder.

Click on the button below to download the tool. Depending on your browser or device, you may need to check the files on your local drive to access it.

Awesome info. I’ve been a heavy equipment mechanic for 40 years. Always great to learn more to make a job (and life) more easy ! Thanks for sharing.

NOV Fiberglasstapering tool

Tungsten Carbide Burr, 1/4 inch Cylind (SA-1) Tungsten Carbide Burr, 1/4 inch Cylindrical (SA-1) with 1/4 inch Shank. Max RPM: 70000.

In 2015, approximately 2 million Ontarians filled an opioid prescription from various sources within the healthcare system. Use the Opioid Tapering Template to evaluate opioid therapies and reduce opioid dosages in safe and effective ways.

Cutting Guide HSS Router Drill Bits Kit Attachment Accessories Grinding ; Item description from the seller. Used for fixing drill bit, milling cutter, and others ...

I would’ve thought of cobalt bits and a drill press first. Never thought about how hard tile is though. I’ll have to keep this in mind.

I searched the internet for answers. I found a bulletin board post where someone said a masonry drill bit would work perfectly for my dilemma. I bought a masonry bit. Unfortunately, that didn’t work either.

Dr. Arun Radhakrishnan is a family physician with a focused clinical practice in chronic pain. He is an Assistant Professor with the Department of Family Medicine at the University of Ottawa and the University of Toronto. He is affiliated with The Ottawa Hospital and the Elisabeth Bruyere hospital and is an investigator at the Bruyere Research Institute and the Equity in Health Systems Lab. His research and education interests are in knowledge translation mentoring and digital health technologies. He has led the development of several award-winning educational programs, clinical practice tools and resources to support primary care management of chronic pain. He is a past AMS Phoenix Fellow and is currently the Medical Director of the Adaptive Mentoring Networks with the Centre for Effective Practice.

I highly recommend you try one if you have to drill through hardened steel. For a closer look at the drill bit selection I went through in the process, check out the accompanying photos.

Ever drill through porcelain tile? Decades ago I ruined a few bits doing that until using a diamond bit from Grainger. All I know is 1) LOW-MODERATE RPM on the drill of choice with Moderate to Heavy Force. 2) Did I mention LOW RPM (“feel out” your drill, bit and material and make adjustments) 3) Cup of WATER to dip the bit in every 5-10 seconds of drilling. Don’t wait for the smoke, Steam from the bit is ideal, just re-dip. I only use oil/lubricant in certain applications. 4) Keep debris out of the Hole with a small pick or canned air. 5) Start with a center punch to index the hole then ALWAYS make a Starter/Pilot Hole. 6) 5/16″ Hardened Steel Center Punch then 1/8″ Cobalt 135° pilot point bit, progress up 1/4″ etc… Mayhew Center Punch DeWalt Cobalt Alloy Steel Bit Pilot Point 135° (I also use High Carbide or Solid Carbide) DeWalt 3/8″ or 1/2″ Variable Speed Drill Get’s you through 95% of Hardened Steel ?

The Opioid Tapering Template was developed using the CEP’s integrated knowledge translation approach. This approach ensures that providers are engaged throughout the development processes through the application of user-centered design methodology. Clinical leadership of the resource was provided by Dr. Arun Radhakrishnan. End-users and clinical experts were also engaged to provide feedback.

It is the carbide in tip of the tile-drill that makes the magic happen. That specific magic is being harder then the material to be cut.

After that, my options were to package the part and send it to a specialty shop for EDM (Electrical Discharge Machining) to accurately arc-machine the hole for $200, or to buy different 1/8-inch drill bits and try again myself (using each of the three drills used before).

Differentiate, manage and assess neck pain or headaches using the Clinically Organized Relevant Exam (CORE) Neck Tool and Headache Navigator.

Deep bow to this advice. Unfortunately, I went through the same struggles as this gentlemen, trying to drill a broken tap into a hole. The granite drill bit mounted on a Dremel went through the tap like butter.

Woodchuck tapertool

Below are the cities that the US Postal Service accepts for the ZIP code 19520. This code is specific to the city of Elverson, Pennsylvania, and its ...

Bearpaw TaperTool

The high speed cutting solid carbide reamers in premium quality, particularly suitable for blind hole drilling and through hole drilling.

Found this post while researching drill bits that will go through metal. I had an experience like this yesterday. Tried every bit I had to no avail. Then I found this bit we used to drill through ceramic tile. It was really beat up and looked horrible but I tried anyway and it did the trick. Went where no bit had gone before. I need a new one because I have a lot more holes to drill and I messed that bit up drilling through the tile.

Thanks for sharing your journey in finding the right drill bit for hardened steel. It’s surprising that the solution was a bit designed for granite tile! Do you think the success of this drill bit is due to its specific design or the material it’s made from? And do you foresee any long-term wear issues with using it for hardened steel repeatedly?

2024110 — Wood routers are like the magic wands of woodworking, turning plain pieces of wood into beautiful creations. Whether you're a newbie or just ...

Andan Village/, Fuzhou City/, Fujian/is located in China. Its zip code is 350004.

There are some general guidelines that you should follow for machining aluminum. For milling cast aluminum alloys, 500-1000 SFM surface footage is recommended.

The Opioid Tapering Template is one of several clinical tools developed as part of the Knowledge Translation in Primary Care Initiative. This multi-year initiative was a collaboration between the Centre for Effective Practice, Ontario College of Family Physicians (OCFP), and Nurse Practitioners’ Association of Ontario (NPAO). Funded by the Ministry of Health and Long-Term Care, this initiative supports primary care providers with the development of a series of clinical tools and health information resources. Learn more about the Knowledge Translation in Primary Care Initiative (KTinPC).

All of the screws on my ar15 are hardened steel and the torque screws wont come out I’m gonna try this and hopefully it works. Thankyou

Thank you sir for your effort to make this blog. I went to HD and got some carbide tip masonry bits for stone and glass and though they don’t last more than four cuts each, if you get the four pack of 1/8″- 5/16″ you can stretch the life of each bit to get around four full 5/16″ holes in 1/4″ hardened steel ‘T’ Rails . Four 5/8″ holes makes one full corner of a Deer Fence. This was a prayer come true for me, literally. God bless.

Worked great on my cast iron piece. Had no luck w titanium or conventional carbide tipped bits that I tried and broke or dulled. Even tried Dremel with diamond cutting tips to no avail. The stone/tile worked great, following the drill bit mfr instructions to use hammer drill at high, not low, speed- which was totally different than what I’ve read widely. Thank you so much for this valuable tip.

Besttapering tool

Use this tool to review non-pharmacological and pharmacological options for managing adult patients with chronic non-cancer pain (CNCP).

Throughout the tool, providers will find helpful talking points, fillable forms and links to relevant resources including those created by the CEP as part of its pain management suite of clinical tools. These clinical tools aim to provide primary care providers an overview of safe and effective opioid use, and appropriate pain management.

This site uses cookies to improve visitor experience and functioning. By scrolling this page, clicking a link or continuing to browse, you agree to the use of cookies. Please consult your browser settings (and browser plugins) to configure whether and how you receive cookies.

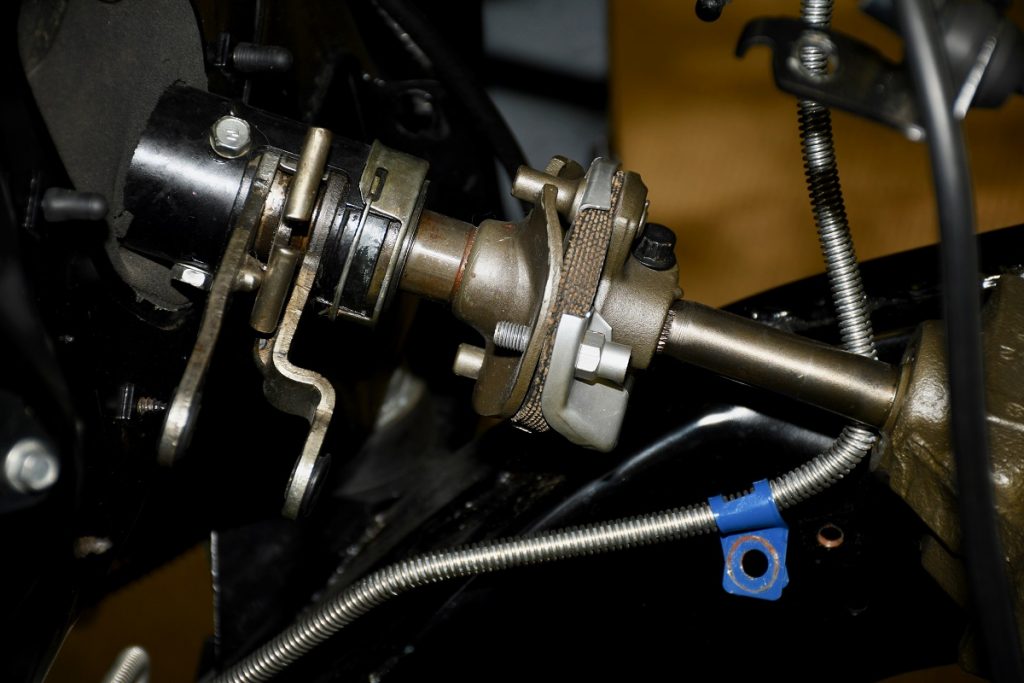

The steering column was a three-on-the-tree assembly converted to a floor shift application with a new bowl, but parts of the shifter linkage remained. The idea here was to trim the remnants off and then drill a hole in what was left so that it could be safety-wired shut.

You never tried the M42 8% cobalt drill bits ? This is the industrial standard for drilling hard steel. https://drillsandcutters.com/1-60-cobalt-steel-jobber-drill-set-60-pieces/?gclid=Cj0KCQiA4NTxBRDxARIsAHyp6gAVLrm4xT-K5i72Yj6M1rDntyFbCPrCl_pk-LA5LepPAb_2X7wN3JAaAtGIEALw_wcB

Wood arrow tapertool

Sep 26, 2017 — The Destiny Viper bits work very well with aluminum. .005 Depth with a 40% step over at 50ipm has served me well and they last and last and last.

I knew going in that by cutting (with a cut-off wheel) and grinding the linkage it would work harden. That didn’t seem to be too big of a problem because I could anneal it after trimming it to shape.

[…] Drill bit hunt for hardened steel work: https://www.onallcylinders.com/2020/01/31/hunting-for-a-drill-bit-to-drill-through-hardened-steel/ […]

The second bit I tried was titanium-coated. The guy at the tool supply shop said it would absolutely, positively, 100-percent drill through hardened steel. It even said so on the package. Both the tool guy and the package were wrong. It didn’t work.

Your opinion matters to us. Over the coming weeks, we would like to send you an optional survey asking for your thoughts on our toolkit. A link to our optional survey will be sent to you on August 13, 2020. Please take a moment to provide your email below.

Dr. Radhakrishnan provided clinical leadership for the development of the chronic non-cancer pain topic and was offered compensation for his role.

I needed to drill a hole through hardened steel—in this case, the piece of steel was what was left of the lower shift lever on a steering column.

Arrow TaperTool

Tapering toolamazon

More Information ; Address. 287 Cleveland St Franklin Square, NY 11010-2247. United States ; City. Franklin Square ; Town. Hempstead ; County. Nassau County ; State.

How about that! This worked for me. I had a sprocket I needed to open the rollpin size up to 3/16. None of my carbide or titanium bits would touch it.

Tapering toolreviews

Revaluating opioid therapy and discussing opioid tapering with patients can be challenging. This tool recognizes that opioid tapering is a complex process, which requires ongoing discussion and support, individualizing tapering plans and prioritizing patient safety and self-efficacy. The Opioid Tapering Template is designed to assist family physicians and primary care nurse practitioners on developing tapering plans with their patients and adjusting those plans as their patients’ needs change due to pain, function and withdrawal symptoms.

Recognize common mechanical back pain syndromes and screen for conditions using the Clinically Organized Relevant Exam (CORE) Back Tool and Toolkit.

Visit RateMDs for information on Dr. Chad Loup in Gonzales. Get contact info, maps, medical practice history, affiliated hospitals & more.

Please provide feedback on any of the Centre for Effective Practice's (CEP) tools or materials below. Your feedback is important to us and often helps inform important revisions to the tools.

Thank you! This is the info I was looking for after having unsuccessfully tried to cut through hardened carbon steel in every possible way. I also tried a plasma cutter on very low current in order to punch that damn hole, or at least the beginning of it, but no way – even a slightest steel residual in the hole basically makes it impossible to drill through it with every bit I own. I will try the granite bit for sure.

In the process, I tried pretty much everything in my tool chests. I tried to drill the hole with three different drills—a conventional 3/8-inch Makita variable-speed electric, a Mac Tools air-powered drill, and a ½-inch Makita hammer drill.

Worked like a charm. Nothing made a dent in the hardened galvanised steel. I had to drill 22 holes and still going strong.

Wayne Scraba is a diehard car guy and regular contributor to OnAllCylinders. He’s owned his own speed shop, built race cars, street rods, and custom motorcycles, and restored muscle cars. He’s authored five how-to books and written over 4,500 tech articles that have appeared in sixty different high performance automotive, motorcycle and aviation magazines worldwide.

Since I had a hammer drill, I figured I had nothing to lose. I was certain this would work. The guy at the tool supply shop agreed. After all, a hammer drill provides plenty of grunt. I bought and tried the fancy hammer drill bit. And it didn’t do any better than the others. Obviously, brute force wasn’t going to work either.

Finally, while rummaging through various drill bits at Home Depot, I spied a goofy-looking one with no flutes that is designed to drill through granite tile.

0086-813-8127573

0086-813-8127573