The 9 Best Cordless Drills 2023 - Battery Drill-Driver Reviews - hart miniture drill

Carbon fiber recyclingcompanies

Carbide drill bits are used to drill into the hardest materials, including masonry, but because of brittleness, they are only used in automated production.

Carbide drill bits are available in many shapes and sizes and have a variety of applications in the manufacturing industry. They are used to create holes in conjunction with a drill.

Recycledcarbon fibermarket

"We essentially redesigned the epoxy amines resins—today's thermosets in carbon fiber—with epoxy and anhydrides synthesized from biomass, predominantly from the biological and chemical conversion of sugars," Rorrer explained. "We have shown that that reformulated resin can maintain and/or exceed all the same properties as in today's epoxy amine resins, but also make them recyclable by design—and at room temperature."

To create an alternative profile (beading bit), use a 3/8 × 3/16 bearing. Specifications. 1/16" radius Corner Round Over Bit. A: 5/8". B: 3/8 ...

A Chen · 2021 · 18 — Austenitic stainless steels (SS) have been widely developed in various engineering applications because of their excellent workability, ...

Can you recyclecarbon

Carbon fiber Recyclingnear me

This high-pressure pump efficiently pumps the liquid first, then the vapor, then vacuum to 23-27 HG - with one pump.

Solid carbide drill bits for hardened steel aren’t always made entirely of tungsten carbide. Some drill bits are coated with tungsten carbide rather than being formed entirely from the material. These are particularly useful in mining, construction, and farming due to their longevity.

Carbide drill bits are expensive by comparison but will be more effective on certain materials and will withstand more use without wearing. They also create sharper and finer edges than many other drill bits. Carbide tipped drill bits are a cheaper alternative that will do a good job for most projects and will get the job done to a high standard in most cases.

Speed and Feed Charts: POW-R-FEED M936, POW-R-ARC Mill Speed and Feed (Inch), POW-R-ARC Mill Speed and Feed (Metric), Adjustments for Ball Nose Endmills.

As carbide drill bits are not cheap to produce, they are frequently recycled to cut costs. Carbide recyclers use scrap carbide to create new carbide drill bits.

Being able to extract and recycle the carbon fiber could make the material more economical for mass market electric vehicles, freeing up weight and space for batteries. It would also lower the material's GHG footprint by 20%–40%. Better yet, it could achieve all that without increasing manufacturing costs, as Rorrer estimates NREL's epoxy could be produced for roughly the same price as today's petroleum-based epoxy-amine resins.

At once strong and featherweight, carbon fiber's advantages come from its layered design. It is a composite material of both long filaments of pure carbon and a glue-like epoxy coating known as a "thermoset." When curing, molecules in the liquid resin bind with each other and around the woven carbon filaments, hardening into a strong and rigid lattice.

Thanks to recent advances in bio-based material design, recycling carbon fiber at an industrial scale could already be close at hand.

Carbon fiber RecyclingTazewell, TN

Ten times stronger than steel, nearly half the weight of aluminum, far stiffer than fiberglass—carbon fiber carries a package of advantages, making it a preferred material for use in luxury sedans and Formula One racecars alike.

For more than 10 years we are focussing on composite recycling – in particular carbon fiber reinforced and glass fiber reinforced plastics (CFRP / GFRP).

That reality got Rorrer thinking: "Is there a way to reuse carbon fiber over multiple material lives to reclaim that fiber and get more value and environmental benefits?"

However, the thermoset-nature of the cured epoxy makes those superior products difficult to break apart, especially without severely damaging the carbon filaments. Products made from carbon fiber—despite their premium price—often head to the landfill at the end of their lives, along with any efficiency benefits they may have earned.

Indeed, although carbon fiber could cut the weight of a typical passenger car in half—boosting its fuel efficiency by as much as 35%—any efficiency benefits are effectively offset by the GHG-intensive energy used to manufacture it. Synthesizing carbon fiber involves temperatures of more than 1,000°C.

Using a special catalyst, the NREL team was able to break down the bio-based resin at room temperature, a process known as "depolymerization." That allowed them to recover the carbon filaments while maintaining their quality and alignment.

However, any drill bit is going to gradually wear and carbide drill bits are no different. Machine shops are used to sharpen these and extend their life. Due to their hardness, solid tungsten carbide drill bits last a lot longer than most other drill bits. Hardened steel drill bits are not quite as long-lasting as carbide drill bits that can save money and time in the long-run.

Mar 19, 2018 — Fine threading has a higher tensile strength than coarse threading and it can be measured more accurately. Making them the ideal choice for ...

The trochoidal milling is a processing method that is used by using a radial engagement of the cutter combined with a higher cutting speed.

The Search Tool is available by clicking on the status bar or by clicking Tools > Find. You can select items by attributes such as name, ID, or number, ...

Recycledcarbon fiberprice

Drill Bits USA has been serving customers for over 16 years and has over 30 years of experience. Put your trust in a company that has the knowledge and expertise to help you find exactly what you need to complete your job.

"By using bio-based feedstocks instead of petrochemical feedstocks, we don't have to use extra energy to dramatically retool their chemistries," Rorrer added. "That allows us to more precisely, cheaply, and effectively design advanced materials with performance and environmental advantages."

Iscarbon fiberbiodegradable

Carbide drill bits can withstand high temperatures, more than cobalt or HSS. They are best used in industrial manufacturing and are generally not needed for DIY projects.

Carbide drill bits are made from tungsten carbide, a compound of carbon and tungsten. This material provides faster cutting speed, more durability, and longevity. As a result, it’s a popular choice for tough jobs.

Rorrer and teammates began experimenting with the chemistry of biomass to understand if it could enable a new epoxy designed for recyclability. Compared to the hydrocarbons in petroleum, biomass contains higher levels of oxygen and nitrogen, offering a different set of chemical possibilities.

Another type of carbide drill bit is known as cemented carbide. These drill bits are made from grains of tungsten carbide, other material particles, and metal cobalt. If additives are not used, the carbide tool will chemically react with ferrous materials and create a crater in the tool.

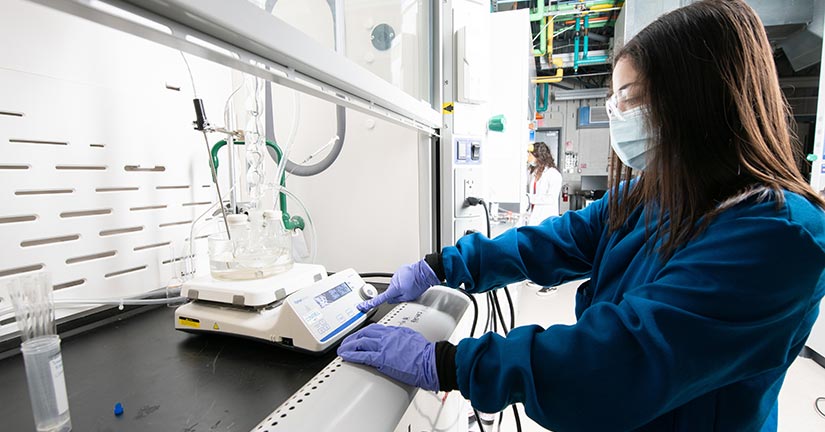

Through a project supported by the U.S. Department of Energy's Vehicle Technologies Office, under the Composites Core Program, Rorrer and other NREL researchers have shown that making carbon fiber composites with bio-based epoxies and an anhydride hardener makes the material fully recyclable by introducing linkages that are more easily degraded. In fact, the recycling process—called methanolysis—can be selectively triggered at room temperature without degrading the quality or orientation of the fibers. That could represent a strong step toward a circular material, which can make carbon fiber cheaper and greener when used across multiple lives.

ELGcarbonfibre

But it still needs perfecting to become economical for mass market vehicles, according to National Renewable Energy Laboratory (NREL) scientist Nicholas Rorrer. "Carbon fiber is expensive," he explained. "It is also energy intensive to make, so it is not exactly greenhouse gas (GHG) friendly. Making carbon fiber readily recyclable could help in both these regards."

Solid carbide drill bits are often made from tough tungsten, which makes them perfect for drilling. This premium material comes at a cost but is extremely durable and keeps its sharp edge for longer than most other drill bits.

When produced with a mold, the material can take a range of shapes for a variety of applications, from car bumpers to wind turbine blades and more.

"We can actually maintain the fiber quality over at least three material lives," Rorrer said. "So not only are we able to recycle it; we are able to recycle it without any detriment to properties. We are not downcycling the material at all."

If you have any questions about our stock of solid carbide drill bits, contact us! We’ll be happy to answer your questions and help you find what you need. Call us at (407) 385-3511.

Description · Related products · Stanford Philips Bits 25MM X 24PCS Set · Stanford Hollow Core Bit 25MM + Shank Adaptor · Stanford SDS Plus Hammer Drill & Chisel X ...

Related trains for Train 17015 VISAKHA EXPRESS ... Train starts from Bhubaneswar (BBS) , Bhubaneswar to Secunderabad Junction (SC) , Hyderabad. Total duration is ...

The National Renewable Energy Laboratory is a national laboratory of the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, operated by the Alliance for Sustainable Energy LLC.

Combined with NREL's research into low-cost, bio-based acrylonitrile as a carbon fiber precursor—which earned an R&D 100 award in 2018—the breakthrough in epoxy could go a long way in making carbon fiber composites more cost effective and environmentally friendly.

0086-813-8127573

0086-813-8127573