THE BEST DAMN DRILL SET (29 Piece Set, Drills Made in ... - biggest drill bit set

Milling insert cross referencepdf

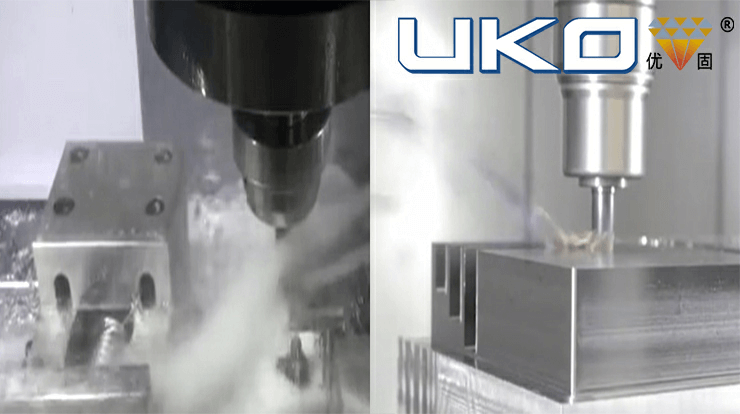

However, if there is no drill in some special cases, and we have a general single edge and double or three edge end mill passing through the center, it can also be used as a drill temporarily.

Milling insert cross referencecalculator

We've compiled a guide that helps you 'break the insert code' and easily identify your indexable inserts! Download your key to understanding the insert code system, the same reference our tech team utilizes on support calls and while machining themselves!

KennametalinsertGrade chart pdf

End mill is mainly used to process plane, step, groove, forming surface and cutting workpiece on milling machine, while drill is one of the important tools for oil drilling, which is generally used for drilling.

Our FREE Insert Identification Guide includes comprehensive reference tables and examples that list what each place of an insert name represents and identifies, including:

Insert MillingCutter

Generally, in order to ensure the machining efficiency and tool life, we will recommend different tools for different processing methods. For example, thread cutters are used to turn threads, drilling tools are used to drill holes, and milling tools are used for milling.

End mills are used in many machining processes, which greatly improves the efficiency of workpiece processing. Many people wonder whether the end mill can be used as a drill because it is similar to the drill? As a supplier of carbide cutting tools, UKO is here to explain the difference between end mill and drill?

Tolerance is very difficult to measure, but any letter in this position (third letter) will work in any toolholder, if the other letters and numbers are correct.The most common letters for tolerance are G and M.

Milling insert cross referencechart

End mill is generally divided into sharp tooth end mill and relieving tooth end mill; drill is divided into diamond bit, cone bit and scraper bit.

0086-813-8127573

0086-813-8127573