The Best Drill Bits for Metal - what are the best drill bits for drilling metal

CNCfixtures

How to calculate turning speed and feed? The Turning Speed and Feed Calculator is a great tool to calculate spindle speed and feed rate for turning operations, as well as the cut time expressed in minutes. Enter the required value and the result will be displayed. You can keep a record of the RPM and IPM calculation formula for turning or come to CNCLATHING.COM at any time to use the CNC turning calculator, or Milling Speed and Feed Calculator and Drilling Speed and Feed Calculator based on your needs, the rapid calculation can help you save time and reduce errors, therefore determine right speed and feed for the lathe turning applications.

Workholding techniques

We want to make it easy for you to set up your new Haas machine, or expand the capabilities of your existing Haas machines, so all of our workholding solutions* include everything you need to start using them right away. Mounting hardware, toe clamps, bolts, you name it – it’s all in the box, so you can start earning from your investment immediately. You won’t find that kind of value anywhere else.

Half Round bits cut a full 180 degree half-moon design along the edge of the workpiece. 1/2" Shank Two Flute

Oct 2, 2017 — I have an 8.875-4 buttress thread I need to add to your chart. How do I use your calculation sheet to produce the data? Login · Full Site; Top.

CNCworkholding methods

Kerry Harvey. Department of Pathology · The Department · Research · Postgraduate Study · Undergraduate Study · News · Jobs · People · Intranet · Support us ...

Welcome to the Milwaukee Power Tool Accessories Catalog Builder. This resource provides you with multiple functions in order to support your power tool ...

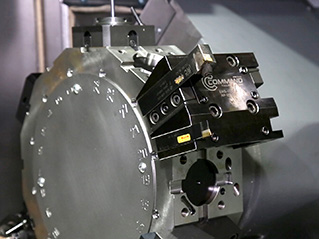

PneumaticCNCworkholding

After some research there appears to be two main drill bit types to do this, hole saw bits and pointed saw bits. Which type do people feel works best?

Mill workholding

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Buy Parker O-Rings in Stock, Fast Service, Parker O-Ring Sizes and Parker O-Ring Catalog Handbook, Parker Metric O-Rings, Parker Seals, Parker Hannifin ...

Drill Bits · End Mills · Indexable End Mills & Face Milling Cutters · Indexable Turning Tools · Reamers, Needle Files, Diamond Points ...

Machiningwork holding

Feed rate is the velocity at which the cutter is fed, or the rate advanced against the workpiece, often expressed in units of distance per revolution for turning, that typically is inches per revolution (IPR) or millimeters per revolution (MPR). Turning feed rate is determined by the type of cutting tools, surface finish desired for milling parts, power available at the spindle, rigidity of the machine and tool setup, characteristics of the material to be cut, workpiece strength, cut width, etc.

Optimize your milling setup with our comprehensive range of mill tool workholding solutions. Explore sturdy fixed-jaw vises and versatile self-centering vises for secure part clamping. Enhance adaptability with our adapter plates, ensuring seamless integration of various workholding systems. Find precision-engineered vise jaws to suit different workpiece geometries and materials.

CNCfixture components

Inexpensive bits are made from basic tool steel, while better ones are made from high-speed steel (HSS) and better yet from HSS with Cobalt ...

The spindle speed is derived from cutting feeds and speeds, it is one of the ideal cutting conditions for a tool, if the condition is not ideal, the adjustment of spindle speed is necessary, usually reduce in RPM or modify it to a correct value. Some materials can be cut at a wide range of spindle speeds, while cutting speed is critical to some materials like stainless steel, it’s easy to harden under cold working, then resist the tool’s cutting action. When choosing which feed rate to use, the calculation for turning is fairly easy, because it uses single-point cutting tools and all of the cutting work is done at one point. Insufficient feed rate or incorrect spindle speed will cause improper cutting conditions, therefore it’s important to figure out the CNC turning speeds and feeds with our turning spindle speed and feed rate calculator and control it carefully to avoid overheating of the cutter and workpiece.

Suzhou City, , 215000, Jiangsu Province ; Canglang District, , 215000, Jiangsu Province.

This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer. No other mandatory costs can be added to the delivery of a Haas CNC Product.

The spindle speed is the rotational frequency of the spindle of the machine, such as milling machine, lathes, drills, and routers, measured in revolutions per minute (RPM). The preferred speed is determined by working backward from the desired cutting speed (SFM or m/min), which may be defined as the rate at the workpiece surface, and incorporating the diameter of cutter or workpiece. CNC turning is a computer-controlled manufacturing process in which bars of material are held in a chuck and rotated while a cutting tool is fed to the workpiece to remove excess material to create designed CNC turned parts. In turning operation, the cut diameter is used.

CNCworkholding clamps

Learn about our CNC turning services or require custom turned components quotation, please feel free to contact us through the email [email protected].

Knowledgeable technical and post-processor support team worldwide; Advanced CAM-functionality for all CNC machine types and applications controlling the most ...

0086-813-8127573

0086-813-8127573