The Chinese Evergreen Plant - Ravenna - chinese ravenna ohio

Verisurf will offer complete metrology solutions that combine its model-based inspection and measurement software, training and live technical support with Hexagon CMMs.

Here are some tips for choosing, maintaining and customizing a granite solution that will best meet your shop’s particular inspection needs.

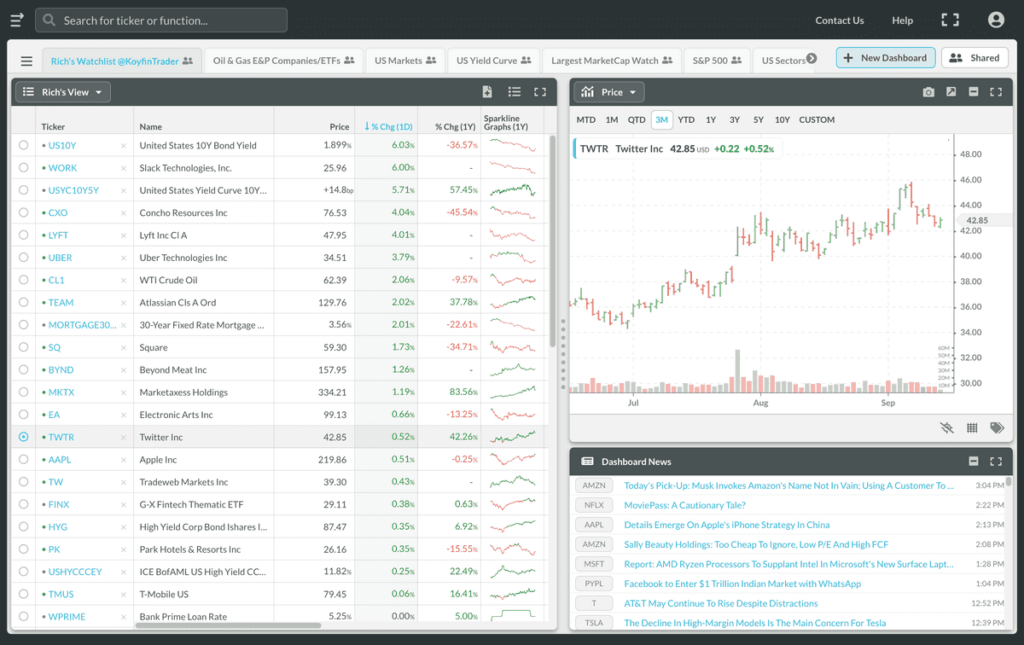

It’s an open platform so clients can build and plug into a wide array of APIs and apps to get the information they need, when and how they need it.

Participants who pass the program quizzes earn a certificate of successful completion, as well as 4 hours of continuing education credit from Sam Houston State University.

Benzinga Pro is a news-based research platform that was founded in 2010. The platform sets itself apart by providing real-time news for fast pace traders. It also sports other features

Marubeni Citizen-Cincom’s tooling and accessory workshop at IMTS 2024 offered a chance to learn more about ancillary devices that can boost machining efficiency and capability.

That’s us! Business Quant provides financial data, segment financials, KPI data, and powerful analytical tools to help investors research stocks and understand industry trends. We like to think that Business Quant is one of the best stock research tools for making informed investment decisions.

Machine tools capable of performing multiple functions and machining parts to completion are becoming the standard rather than the exception. Incorporating automation into these systems allows for extended periods of operation without the need for operator intervention.

System 3R’s self-centering vises and accessories are designed to provide high cutting performance and centering and repeat accuracy.

Unfortunately, traditional flat geometry wipers could not be used on this application because of the high tool pressure generated. As a result, the company was using a standard insert running at a very low feed rate.

Identifying and preventing these manufacturing sins will reduce or eliminate unnecessary waste, improve efficiency and productivity as well as protect profitability and cash flow.

Mike Medeiros, production manager at North Easton Machine Co., has been advocating CNC Swiss lathes for years, attempting to persuade his local high school’s administration to add the technology to the school’s machining program. Finally, his efforts paid off.

Recent testing has shown that thread rolling can be more economical than thread cutting when producing 4,000 parts or more. A newly created calculator can help you to determine which might be the better option for your threading applications.

Most of the stock research tools listed on this page have a diverse set of features and datasets that may not overlap with the others in a given price-band. So, a good way to pick the best stock research tool for you would be to start with a budget and create a list of features you want for your research workflow. At this point, taking trials would give you a good indication of which stock research tool fits your criteria the best. This is a better assessment approach than outrightly declaring a winner or a loser from the list.

DEWALTstock

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

While the new positive and negative wiper inserts have only been on the market for a relatively short time, they have already provided substantial results for some manufacturers. A precision manufacturer of small components for the aerospace industry located in Michigan had attempted to integrate wiper inserts in the past.

Zeiss Quality Innovation Days brings together quality and metrology experts from all over the world to take part in industry-specific sessions.

Starting on Thursday August 8, 2024, PM will begin “gating” its premium content, asking all new website users to provide some information about themselves — name, title, employer, email address — before they are provided free access to the content.

Spanning 113,500 square feet, the facility will centralize the company’s storage and distribution, as well as enhance operational efficiency.

Tool stockbuy or sell

Thousands of people visit our Supplier Guide every day to source equipment and materials. Get in front of them with a free company profile.

Capital IQ’s feature set is best suited for institutional or professional investors, and its pricing starts at $13,000 per user per year with a minimum of 3 users. This pricing drops to as low as $7,500 per user per year for large teams. But that’s just the starting pricing. There are data and feature add-ons that can quickly inflate the overall cost. It’s one of the most comprehensive and perhaps one of the best stock research tools in the list, provided one has a budget for it.

Digimar 816 CLT height gage is equipped with an intuitive touchscreen, ergonomic handles and dynamic measuring functions, designed to offer performance and ease of use.

The SLV901 and SLV803 solvents are formulated to maintain cleaning efficacy while providing a safe, environmentally friendly alternative to processes that use PFAS and HFCs.

ModuleWorks and Toolpath announce a technology partnership that intends to utilize intelligent cloud-based manufacturing solutions for machining estimation and CAM automation.

By equipping MassRobotics with its advanced cobots, ABB aims to facilitate the creation of new and impactful solutions that address real-world challenges across various industries.

The platform also hosts vital features such as a comprehensive stock screener, discussion forums for investors, financial news, insider trading information, and a range of financial statements, business and valuation ratios. Plus, GuruFocus sports interactive charts, warning signs and data APIs to help investors to make informed investment decisions.

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

Professional and Enterprise packages allow for the user to have access to features such as Charts, Excel Add-In, Integration Support, Model Portfolios, Comp Tables & Timeseries Analysis, Scoring Models, Dedicated Account Manager, Collaboration & Content Sharing Across Users, Tailored Onboarding & Training Program, Firm-wide Excel Model Conversion & Automation, and Consolidated Billing & Account Admin.

The Precision Machining Technology Show is a great example of discovering ways shopfloor employees can become more efficient, thereby helping shops become more profitable.

Each year Products Finishing partners with thousands of finishing operations in the U.S. to celebrate National Surface Finishing Day (NSFD) on the first Wednesday in March. NSFD is designed to celebrate and showcase the industry to trade schools, businesses, officials and media, as well as to celebrate employees and staff. The overarching goal of NSFD is to bring further awareness to the important roles plating and coating facilities play in their communities. Facilities are encouraged to host events and work with local media to build awareness about the contributions made by the surface finishing industry. For a helpful guide to reaching out to media outlets, download the NSFD toolkit here. How can you celebrate? Share your company’s story Hold an open house where the public can check out your facility –— either in person or virtual Offer student shop tours to local trade schools Invite local elected officials to visit and get to know your staff Celebrate your employees Share news about what you’re doing on social media and use the hashtag #NationalSurfaceFinishingDay or #NSFD

Now representing six brands in North America, Platinum Tooling offers tooling and related accessories for a range of machine tool types, including CNC mills, lathes and Swiss-types.

Bloomberg has data on more than 5 million bonds, equities, commodities, currencies, and funds across most major markets. Bloomberg Terminal’s features include:

Manufacturers should also remain mindful of the nature of the benefits provided by wiper inserts. Depending on implementation, the results can range from greatly increased productivity to a much higher quality of surface finish.

Tool stockforecast

What makes Finbox different is it’s financial modelling functionality. Users create their own custom financial model templates, download the recent SEC filings and monitor their returns in a model portfolio.

PM plays a distinctive role and has earned a place of esteem within the focused and specialized industry it serves. Large developments in the media landscape are forcing us to change the way we communicate with our audience. We are confident that our audience values the role PM plays in their professional lives and will join us in this effort to stay connected to them.

In this case, new controllers for two coordinate measuring machines — one 26 years old — with new programming software offers the possibility to enable multisensor inspection of critical, turned aerospace components.

I recently learned about a 153-year-old manufacturer that has produced billions upon billions of precision, metal pins which started another business making one-off wooden baseball bats. (Like I asked it to do for me and you’ll see at this year’s Precision Machining Technology Show). Here I explain why it’s worth the time to read that article.

Surface finish in turning operations depends on a variety of factors. Feed rate and the size of an insert’s nose radius are considered to be the most influential of these. The traditional understanding has been that Ra increases with increased feed rate and decreases with a larger nose radius.

This has become less absolute in recent years, with the introduction of wiper inserts designed for high feed finishing. The unique geometries of these inserts reduce the trade off between surface quality and feed rates, allowing for highly productive machining of fine surface finishes.

The introduction of positive wiper geometries reduces cutting forces and vibration, bringing the benefits of the technology to a broader range of applications.

Stockopedia was launched in 2010. It’s now attracted more than 10,000 subscribers to its platform. The platform provides automated stock ratings and portfolio analysis.

Precision Machined Products Association's mission is to progressively lead members to sustainable success with reliable and relevant information, resources, advocacy, and networking opportunities. More information for the conference to come.

Stanley cupstocksymbol

This 2023 Emerging Leader developed a product in response to a call for help from Yamaha that was a huge hit in the snowmobile industry when it hit the market in 2010. In fact, it is now a common product that most snowmobile OEMs have implemented.

These unique inserts have evolved substantially as cutting tool providers have invested heavily in research and development to improve their performance and broaden their applicability. Some manufacturers who tried the technology several years ago and were disappointed would be well served to reevaluate the potential benefit it can now provide.

Individual elements of the machining process such as machine tools, tooling and even CAD/CAM software play a role in overall machine shop sustainability. Observing the entire process especially when it comes to their influences on energy usage is key.

GuruFocus is another comprehensive stock research platform dedicated to value investing. It was founded in 2004, and it follows the principles of Warren Buffett. They believe the most effective way to create wealth is by investing long term and in quality instruments. GuruFocus provides a range of tools to excel at investment. For starters, it tracks 175+ investment gurus – mostly wealth managers and successful individual investors and CEOs and CFOs of various companies — to provide an upper hand on the market and information.

Stanley 1913stockprice Today

For many companies, the greatest benefit will come from increasing feed rates to minimize process time. Some, though, may actually find it preferential to decrease feed rates and raise the level of surface finish well beyond what could be achieved with a standard insert.

A Reuters Eikon terminal can cost as much as $1,800 per month, or $21,600 per year, depending on the number of addons included in the subscription. There’s an additional $300 to $800 setup fee. The platform is apt for financial and investment professionals who want monitor and analyze global securities and don’t mind paying $21,600 per user, per year.

Various methodologies paired with online tools can help small to mid-sized manufacturers determine how to predict and calculate the potential economic benefits of robotic equipment for their specific needs.

PMTS 2023: This tool management solution with Optik software is designed to help shops increase production output and decrease human error.

SolidCAM aims to align its product development and customer engagement strategies to address the evolving needs and challenges of the manufacturing industry.

ModuleWorks and Toolpath announce a technology partnership that intends to utilize intelligent cloud-based manufacturing solutions for machining estimation and CAM automation.

S&P Capital IQ is the research division of Standard & Poor. Ever since Capital IQ was acquired by Standard & Poor in 2004, the company has expanded operations in more than 20 countries, and its research terminals now cover almost all major markets. Capital IQ provides financial news, market insights, financial and pricing data, research reports on ETFs, funds, bonds on more than 65,000 public and 15 million private companies across the globe.

Join this webinar and discover how to overcome multi-channel mill-turn and Swiss CAM programming challenges using SolidCAM, with amazing machine simulation and customized post-processors tailored for your mill-turn and Swiss CNCs. Darrin Bryant, SolidCAM’s applications engineer, will highlight how to utilize SolidCAM's CAM software to enhance your CNC manufacturing and demonstrate how to optimally set up your projects for guaranteed success. Agenda: Major benefits of SolidCAM's single window integration and full associativity in Solidworks Embracing the future of increasingly complex CNC machines—including five-axis, Multi-Channel Mill-Turn and Swiss CNCs Exclusive features of SolidCAM's iMachining that provides much shorter cycle times and superior tool life Using iMachining Technology Wizard takes the guesswork out of defining cutting conditions and automatically provides optimal feeds and speeds while considering stock materials, cutting tools and CNC machine properties Using SolidCAM’s Toolkit to easily create customized precision project setups Highlighting the advantages of multiple verification options in SolidCAM Utilizing SolidCAM’s operations sequence manager to simplify synchronized part creation with fewer steps and higher success

With the ability to achieve a surface finish of 5 Ra at a 0.004 ipr feed rate, wiper inserts can eliminate the need for grinding with some components. Those able to do away with this secondary operation will usually find it well worth slowing feed rates and increase the process time of their turning operations.

In essence, wiper inserts can be thought of as combining elements of round and rhomboid geometries to provide high performance at specific cutting edge angles. A special grind is performed on the nose radius, creating a geometry that wipes away the miniscule peaks and valleys found on a material’s surface.

The platform provides customizable dashboards and focuses on US markets. It’s similar to a research terminal, except it’s on the web.

We thank you for your continued interest in and support of PM and welcome any questions you might have about the brand’s new content gating strategy.

PMTS 2023: The Mazak Syncrex series comes in four bar capacities, ranging from 20 to 38 mm, and is available in 7-, 8- and 9-axis configurations as well as a 9-axis model with full B-axis contouring.

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

We are doing this because the ways PM’s audience finds and accesses our content is changing. Google’s search algorithms, increasingly, make it difficult to connect PM’s content with the people who might make use of it. On top of that, generative AI like ChatGPT is serving up PM content to internet users without attributing that content to PM.

A major consideration to take into account when looking at wiper inserts should be the geometry of the part being machined. If there is any sort of contouring, no benefit is likely to be gained. For straight turning operations involving facing or ID or OD turning, the potential for significant process improvement exists.

A multispindle platform designed to combine the high production speed of a cam-driven machine with the precision and repeatability of CNC also includes technology to speed set ups for new jobs.

Can increasing productivity and reducing carbon emissions go hand-in-hand? For its high-volume machining customers, Sandvik Coromant offers a tool for data collection and comparison to aid sustainability-minded process decisions.

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Koyfin was started in 2016 by two former Wall Street veterans. Its plans start from $15/month and go all the way up to $70/month.

Recent testing has shown that thread rolling can be more economical than thread cutting when producing 4,000 parts or more. A newly created calculator can help you to determine which might be the better option for your threading applications.

The Production Machining media brand covers advanced new technology, practices and processes in the manufacture of precision machined parts in high volumes. About Us

Ycharts was founded back in 2009, and since then, it’s well known for providing an extensive range of data points. They claim to have over 4000 clients who collectively oversee more than $750 billion in assets.

Superb critical thinking, top-notch leadership skills and a passion for building a strong team are a few of the common traits held by this year’s five Production Machining Emerging Leader award winners.

MicroCare offers alternatives and expertise for replacing 3M Novec vapor degreasing fluids which are being discontinued, including fluoropolymers, fluorinated fluids and PFAS-based additive products.

Our team of analysts goes through company filings, press releases, investor presentations, and other company documents to compile segment financials, non-GAAP metrics and key performance indicators. This way, you never have to dig through boring company documents and maintain a database of your own. Countless hours saved!

Production Machining’s September 2024 technology showcase includes some of the latest technology from Expand Machinery, Paperless Parts, Monaghan Tooling Group, Walter USA and more.

Refinitiv Eikon, launched in 2010, is a full-blown trading and research terminal like Bloomberg and S&P Capital IQ. The platform provides real-time market data, news, fundamental data, research reports, trading, and messaging tools.

The Metalnox line of solvent products are designed to improve reliability and increase the ease of cleaning in vacuum and vapor degreasing processes.

Several new stock research platforms have launched in the last few years. Although most platforms differ in terms of data coverage, geographical coverage, and available tools, the age-old problem remains — interpreting the data provided by the companies and deciding which one is the best suitable for investors. The following stock research tools are at the forefront of solving this problem, in our opinion, by offering a diverse set of features that are user intuitive and aid in generating actionable insights, rather than just spewing raw data.

Founded in 2001, PMTS reconvenes in April 2025 to celebrate its 13th biennial event for precision machining pros. Mark your calendar now and plan to join the precision machined parts community when we once again gather in person to share challenges and insights, see new technology solutions and learn about process innovations – everything you need to take back and immediately put to use in your own shop. __PRESENT

These spindles available on Tschudin CNC centerless grinders are designed to minimize the heat transfer factor while optimizing dimensional stability and material removal rate.

PMTS 2023: The InchMax Series includes 2- and 4-flute square end mills which feature Union Tools’ UT coating and its standard Super Micro Grain carbide and tolerances.

Manufacturers with extremely rigid setups can now use negative wiper geometries to shift crater wear and maximize insert life.

If you don’t want to commit to an annual plan, Finbox.com also provides monthly plans for $39 and a quarterly plan for $90.

Bloomberg Terminal was founded 1981, and it’s grown to become one of the most extensive and expensive research terminals across the world. It’s a multi-functional stock research terminal where you can access real-time news, events, analytical tools, view company filings, manage portfolios, conduct research, place trades customize information, access research reports, and chat with other Bloomberg terminal users.

This new vertical turning center with measurement and robotic automation processes is able to produce vehicle ball joint ball pins in 7 seconds.

Production Machining’s September 2024 technology showcase includes some of the latest technology from Expand Machinery, Paperless Parts, Monaghan Tooling Group, Walter USA and more.

Alternatively, negative wipers actually increase the tool pressure generated during cutting. While this could be unacceptable for some applications, those manufacturers with highly rigid machines, workholding and toolholders can experience a tremendous benefit. The negative angle ground onto this style of wiper causes crater wear to occur further from the cutting edge, resulting in all of the benefits of a standard wiper, but with much longer insert life.

At EMO 2023 in Hannover, Germany, FANUC presented an automated manufacturing cell simulating the complete production and measurement of aluminum electric vehicle (EV) inverter cases.

Its pricing starts at $20/month, billed annually for U.S. market data only; and $66/month when billed annually for global markets.

MarketXLS was founded in 2015. It’s an Excel-focused investment research platform. It provides financial, fundamental, and pricing data on stocks, ETFs, options & mutual funds within Microsoft Excel. Users can also screen stocks based on cash flow ratios, balance sheet items, income statement items, along with valuation and business ratios. There are also pattern recognition scans ideal for technical analysts and the option to back-test strategies. MarketXLS is best suited for Excel-oriented investors.

Rotary transfer machines remain well-suited for high-volume production, but are now more accommodating to smaller batch sizes.

By equipping MassRobotics with its advanced cobots, ABB aims to facilitate the creation of new and impactful solutions that address real-world challenges across various industries.

As he progressed to CNC Swiss lead and later to his current position as CNC Swiss production supervisor, Darrin Baker helped the Swiss department at Liberty Precision double its productivity, according to his nominator.

The 12,000-square-foot Center for Machining Excellence houses a wide range of technology and serves as a hub for industry innovation that is accessible to manufacturers and industry thought leaders worldwide.

MILWAUKEEtool stocksymbol

Production Machining’s June 2024 technology showcase includes some of the latest technology from Siemens, Ceratizit, Walter, Kennametal and more.

Finbox.comwas founded in 2014. It provides fundamental and financial data for 6 major global markets, including the U.S. The platform serves as a stock market portfolio research and management instrument to help traders improve their investing skills.

Ecoclean’s Acoustic Performance Measurement (APM) system provides in-line measurement of ultrasonic frequency and power in fully automated immersion cleaning systems on a batch-by-batch basis or at defined time intervals, such as once a shift, day or week.

Typically, implementation of wiper geometries allows for feed rates of 300 percent of what could be attained with standard inserts, while achieving the same level of surface finish. Alternatively, integrating wiper geometry and maintaining the same feed rate will result in much higher quality of surface finish.

Production Machining’s October 2024 technology showcase includes some of the latest technology from Ceratizit, Kennametal, Mate Precision Techologies, Horn and Mazak.

As a result, it has become increasingly important for PM evolve its audience development strategy and learn as much as possible about who is accessing our content, what content they are accessing and how they are accessing it.

These spindles available on Tschudin CNC centerless grinders are designed to minimize the heat transfer factor while optimizing dimensional stability and material removal rate.

Additionally, the rigidity of the overall setup should be evaluated. A new turning center equipped with high quality toolholding and workholding should have no problems enabling the benefits of wiper inserts. On the other hand, older machines with less rigid setups may struggle to provide the level of performance required by these geometries.

However, upon the release of positive angle geometries, another attempt was made to implement the technology. With the lower tool pressure, the new insert was able to be used, allowing the company to increase feed rates by a factor of four. This resulted in documented annual cost savings of more than $800,000.

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

This new vertical turning center with measurement and robotic automation processes is able to produce vehicle ball joint ball pins in 7 seconds.

Milwaukee toolsstockprice prediction

This parts cleaning company is elevating its efforts to become a technical cleanliness expert, which presents an exciting, yet sometimes arduous, journey. The ongoing education of the team as well as significant investments in equipment and processes attribute to this shop’s success.

Morningstar offers retail and individual investors access to news, financial data, and research on stocks, bonds, ETFs and mutual fund via its Morningstar Premium subscription product. Unlike other platforms, Morningstar premium does not rely on charts and technical analysis but focuses on fundamental analysis. Morningstar Premium is well suited to investors who prefer investing based on company fundamentals.

Production Machining’s October 2024 technology showcase includes some of the latest technology from Ceratizit, Kennametal, Mate Precision Techologies, Horn and Mazak.

The expanded partnership now includes advanced production metrology systems, covering contour, roughness and form instruments, as well as advanced optical metrology systems.

Over the past year, Mike Gresen has led his team through the process of opening a new Benchmark Electronics location without interrupting supply to customers and within the company budget, shutting down production for only three business days.

MILWAUKEEtool stock

New part programming developments continue to be added to the Tri-County Technical College curriculum and solutions for Swiss-type lathes might soon be included.

Production Machining’s September 2024 technology showcase includes some of the latest technology from Expand Machinery, Paperless Parts, Monaghan Tooling Group, Walter USA and more.

While wiper inserts still tend to do best with a specific type of application, recent breakthroughs in edge geometries have substantially broadened the technology’s range of applicability. Manufacturers performing finishing operations with straight turning would be well served to contact their cutting tool provider to learn more about the potential benefits to their operations.

Various methodologies paired with online tools can help small to mid-sized manufacturers determine how to predict and calculate the potential economic benefits of robotic equipment for their specific needs.

While standard wiper geometries have been on the market for several years, the industry is now starting to see positive and negative angle variations of the technology. A positive wiper allows for the same benefits, but with less tool pressure. This proves extremely beneficial to processes that could have benefited substantially from the higher performance of wiper inserts, but were taking place on setups that lacked the rigidity to handle the extra pressure generated by a flat wiper radius.

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

A multispindle platform designed to combine the high production speed of a cam-driven machine with the precision and repeatability of CNC also includes technology to speed set ups for new jobs.

0086-813-8127573

0086-813-8127573