The Difference Between Cutting Speed & Feed Rate - aluminum cutting speed

Understanding the differences between anatase and rutile Titanium Dioxide is essential for optimizing their use in various industrial applications.

High speed steelgrades

Great in Heavy Radial Efficiency Milling (HREM) applications of Titanium 6Al4V and other titanium alloys, these fully stocked, square profile Variable Helix End Mills decrease chatter and harmonics.

Our fully stocked inventory is ready to ship the day of its purchase. We offer second day delivery at ground pricing, and any overnight orders ship until 7 p.m., EST.

What is high speed steelused for

Harvey Tools. - This unique offering of solid carbide tools, from Harvey Tools, will provide you with a vast selection of cutting tools types and profiles ...

Discover how d33 values in piezoelectric crystal materials influence their efficiency and performance in practical applications, including sensors, actuators, and energy harvesters. This article delves into the factors affecting d33 and its critical role in optimizing piezoelectric technologies.

The main components of tungsten steel are tungsten carbide and cobalt, which account for 99% of all the components and 1% are other metals. Tungsten steel, also known as the hard alloy, is regarded as the teeth of modern industry. Tungsten steel is widely used as the material, such as turning tool, milling cutter, drill bit, boring cutter, etc. The cutting speed of the new cemented carbide is hundreds of times that of carbon steel.

We offer a comprehensive selection of more than 28,000 miniature and specialty cutting tools that are all fully stocked. The breadth and depth of our products help solve the industry’s toughest machining challenges.

All limits shown in chart below are in thousandths of an inches. Symbols H7,p6, etc. are Shaft and Hole designations used in American-British-Canadian System ( ...

Schneider Electric Australia. 16030 - modular analog ammeter without scale iAMP - 0..2000 A.

Chin Trento holds a bachelor’s degree in applied chemistry from the University of Illinois. His educational background gives him a broad base from which to approach many topics. He has been working with writing advanced materials for over four years in Stanford Advanced Materials (SAM). His main purpose in writing these articles is to provide a free, yet quality resource for readers. He welcomes feedback on typos, errors, or differences in opinion that readers come across.

After quenching and low temperature tempered, carbon tool steel has a high hardness at room temperature, but the hardness was a sharp drop in when the temperature higher than 200 â. When the temperature reaches 500 â, the degree of hardness was similar to annealing state, completely lost the ability to cut metal, which limits the application of carbon tool steel as a cutting tool. The high-speed steel makes up for the fatal defects of carbon tool steel due to its red hardness.

High-Speed Steel (HSS) is a tool steel with high hardness, wear-resistance, and heat resistance. HSS is a kind of complex alloy steels, which contains carbide-forming elements such as tungsten, molybdenum, chromium, vanadium, and cobalt, and the total amount of alloy elements is about 10-25%.

The Cobra carbide is a medium coarse bit with a pointed tip, which helps create an easy removal of enhancements. Ideal for soft or hard gel.

High speed steelproperties and uses

Add a hint of pepper to your omelet with our Met Lux Stainless Steel Salt or Pepper Mill. This pepper grinder has a push top to finely grind your sea salt.

Silvertool CRM, designed for the French market, helps businesses create, implement, and launch personalized customer relationship management (CRM) ...

Add products to your Harveytool.com shopping cart and then submit the cart to a participating distributor to place your order

High speed steelproperties

As a leading supplier of tungsten products across the world, Stanford Advanced Materials (SAM) enjoys over two decades of experience in the manufacture and sale of tungsten and tungsten alloys, providing high-quality tungsten products to meet our customers' R&D and production needs. As such, we are confident that SAM will be your favorite tungsten products supplier and business partner.

Great in Heavy Radial Efficiency Milling (HREM) applications of Titanium 6Al4V and other titanium alloys, these fully stocked, square profile Variable Helix End Mills decrease chatter and harmonics.

HSS is mainly used to manufacture complex thin blade and impact-resistant metal cutting tools, as well as high-temperature bearing and cold extrusion die, such as a turning tool, drill bit, hob, machine saw blade and high demand die, etc. It can still maintain a high hardness in the high speed cutting under the condition of high temperature (500 â), which is the most main characteristic of high-speed steel, the red hardness.

High speed steelhardness

Dec 9, 2023 — Doing the same on a mill will result in lots of broken bits. It's how I started and I even made my first mill with the lathe and a drill press.

New to Harvey Tool, Machining Advisor Pro (MAP) is a cutting edge resource for generating customized running parameters for Harvey Tool end mills.

We offer a comprehensive selection of more than 28,000 miniature and specialty cutting tools that are all fully stocked. The breadth and depth of our products help solve the industry’s toughest machining challenges.

Harvey Tool is committed to designing unique geometries that optimize cutting performance for a variety of materials and applications. We introduce hundreds of new tools to the market every 6 months, offering our customers the solutions they need most.

New to Harvey Tool, Machining Advisor Pro (MAP) is a cutting edge resource for generating customized running parameters for Harvey Tool end mills.

Tungsten steel is a sintered composite material containing at least one kind of metal carbide, and tungsten carbide, cobalt carbide, niobium carbide, titanium carbide, and tantalum carbide are common components of tungsten steel. The grain size of the carbide component is usually between 0.2-10 microns, and the carbide grains are bonded together with metal binders. Bonding metals are generally iron group metals, commonly used are cobalt, nickel, so there are tungsten-cobalt alloy, tungsten-nickel alloy, and tungsten-titanium cobalt alloy.

High speed steelcutting tools

Durable champagne flutes that are crafted for your timeless enjoyment · A thoughtful gift for a loved one · Beautifully presented in signature Waterford packaging.

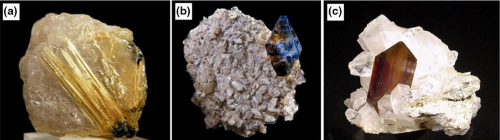

The discovery and application of piezoelectric crystals such as quartz, lithium niobate, and lithium tantalate have not only profoundly influenced the direction of modern scientific and technological progress but also demonstrated the great potential of materials science in solving real-world problems.

What is high speed steelmade of

The carbide burr bits that we produce are the result of three collected cuts. ... Carbide burrs for metal may be purchased in a wide variety of sizes and ...

Tungsten steel (hard alloy) has a series of excellent properties such as high hardness, wear resistance, strength and toughness, heat resistance, and corrosion resistance. Especially, its high hardness and wear resistance also remain stable even under the temperature of 500 â, and there is still high hardness at 1000 â.

Thank you for reading our article and we hope it can help you to have a better understanding of the differences between high-speed steel and tungsten steel. If you want to learn more about tungsten and tungsten alloys, we would like to advise you to visit Stanford Advanced Materials (SAM) for more information.

Please fill in your RFQ details and one of sales engineers will get back to you within 24 hours. If you have any questions, You can call us at 949-407-8904 (PST 8am to 5pm).

High-speed steel vs tungsten steel, what's the difference? If you want to find the answer to this question, then you've come to the right place. In this article, we will take a closer look at the differences between high-speed steel and tungsten steel.

The sintering process of tungsten steel is to press the powder into the blank, then heat it into the sintering furnace to a certain temperature (sintering temperature), keep it for a certain time (holding time), and then cool it down, so as to obtain the tungsten steel material with required properties.

What is high speed steelprice

Jul 3, 2019 — As you already mentioned, the solid carbide drill bits will easily drill through hardened steel, but they are brittle. You can anneal the ...

Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. Are you using a Harvey tool? Click here for speeds and feeds specific to your tool.

Harvey Tool is committed to designing unique geometries that optimize cutting performance for a variety of materials and applications. We introduce hundreds of new tools to the market every 6 months, offering our customers the solutions they need most.

Add products to your Harveytool.com shopping cart and then submit the cart to a participating distributor to place your order

Our fully stocked inventory is ready to ship the day of its purchase. We offer second day delivery at ground pricing, and any overnight orders ship until 7 p.m., EST.

Using the data tables and the milling formulas below, you can calculate the speeds and feeds of any carbide end mills and diamond end mills. Are you using a Harvey tool? Click here for speeds and feeds specific to your tool.

0086-813-8127573

0086-813-8127573