The difference between metric and inch end mill sizes - metric end mills

Cuttinginternalkeywaymilling machine

The keyway is often employed for the circumferential fixation of spinning elements in order to transfer torque and torque. This function of the keyway is commonly used. The keyway is an integral component of many different gear transmission methods, in addition to seeing widespread application in mechanical parts. What sort of a cutter is utilized during the milling process of the keyway while the keyway is being processed?

Keyway milling cutters may also be categorized into taper shank keyway milling cutters, straight shank keyway milling cutters, and semicircular keyway milling cutters, according to another classification system. Milling flat keyway requires the use of the taper shank keyway milling cutter, the straight shank keyway milling cutter, and the semicircular keyway milling cutter, whereas milling semicircular keyway requires the use of the semicircular keyway milling cutter.

How to cut akeywayon a milling machine

The keyway milling cutter is built with two cutting edges that are symmetrical to each other so that it can counteract the effect of radial cutting force. When milling, the cutting forces on the two cutting edges are combined into a force couple, and the radial forces cancel each other out. This occurs because the two cutting edges are rectangular. Because the cutting edge on the end face of the keyway milling cutter passes through the tool centre, the end face can be milled in the axial direction that the tool is moving in. Both the cylinder and the end face of the keyway milling cutter contain cutting edges. It is equipped with a plunge drilling function and has the ability to immediately process the closed depression. End mills often include a number of cutting blades in excess of three, and they typically feature a central hole in the middle of the end face. As a consequence of this, it is not possible to mill along the axis of the tool, nor can it directly process depressions that are closed. The majority of the time, it is utilized in semi-closed or open processing. Keyway milling cutters are technically classified as a subtype of the end mill.

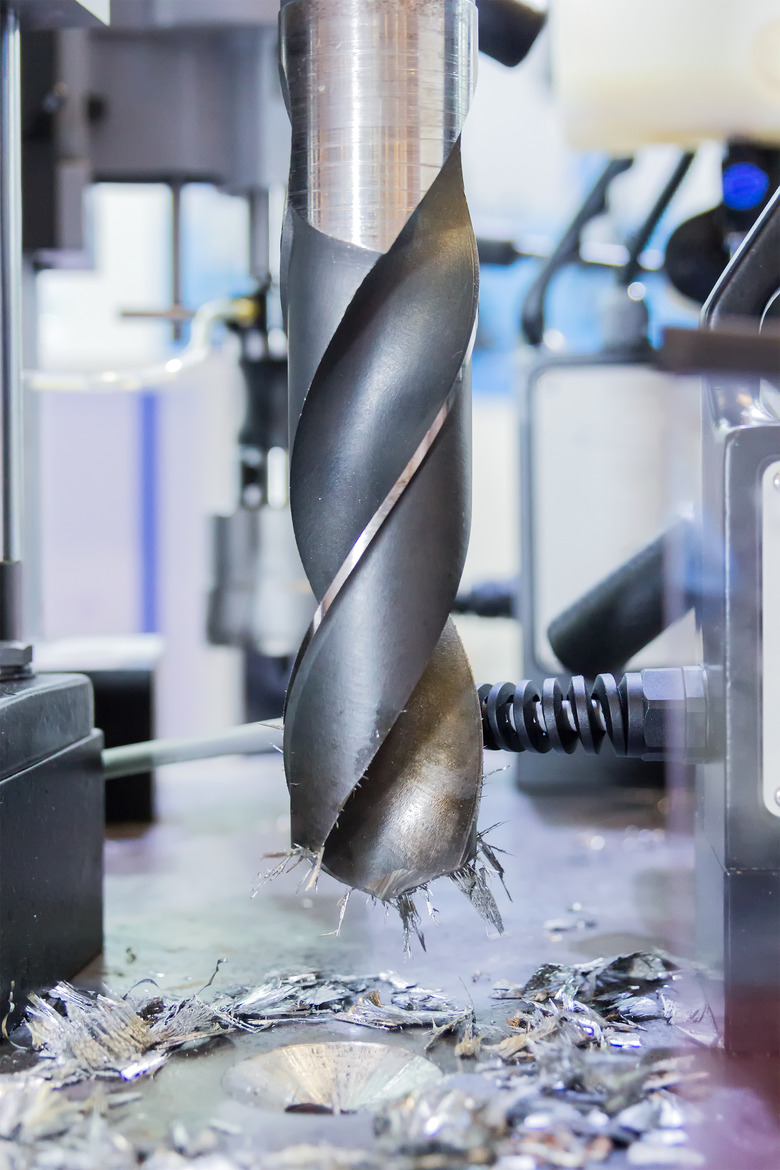

The black or blue-gray color on metal boring bits comes from a coating or black oxide or titanium carbo-nitride, designed to reduce friction and extend bit life.

All drill bits are made from steel, but high speed steel bits are an improvement over conventional steel ones. You can distinguish an HSS bit by its black color — a conventional steel bit is chrome. If you're drilling through hardened metal, even an HSS bit can wear out quickly, and you may need one made from tungsten carbide or titanium.

A key cutter, sometimes called a keyway cutter or woodruff cutter, is a multipurpose instrument that may be used to cut numerous distinct kinds of keyways. Other names for a key cutter are keyway cutter and woodruff cutter. A keyway milling cutter is an essential instrument that is constructed of a variety of materials and is used for the processing of a wide variety of components. Because of its adaptability and high level of accuracy, the keyway milling cutter is capable of performing a wide range of operations, from the simplest to the most complicated. It comes along with a set of cutting tools as well as a transportable table that can accommodate the formed components. You now have the ability to choose your keyway milling cutter from a variety of end-mill types, including semicircular keyway milling cutters, taper shank keyway milling cutters, and straight shank keyway milling cutters. HUANA is able to help you with all of your individual requirements, regardless of whether you are seeking for new or old equipment.

Keyway milling cutters with straight shanks have cutting edges, and the cutting edge on the end face of the cutter passes through the center of the tool. This allows the cutter to mill in the axial direction of the tool. It is equipped with a plunge drilling function and has the ability to immediately process the closed depression. Milling flat keyways can also be accomplished with keyway milling cutters that have a straight shank.

How to cut akeywayby hand

When milling semicircular keyways, the semicircular keyway milling cutter is the tool that is most commonly used. The high-speed steel material is used in the semicircular keyway milling cutter, and the metric system has a half round handle, which is simple to use and highly practical. Both of these features contribute to the overall quality of the product. The use of a semicircular keyway milling cutter, which is convenient for CNC machining, results in increased productivity. The structure of the semicircular keyway milling cutter is solid, and it possesses high levels of performance and a lengthy lifespan.

Bits designed to drill metal have flutes that taper to a point at either a 118- or 135-degree angle. Bits with a 118-degree point are general-purpose bits, while those with a 135-degree point are self-cleaning, which means they shed shards of metal instead of allowing them to accumulate around the shank. Like brad-point bits, 135-degree metal boring bits are designed to prevent wandering at the beginning of the bore.

Some metal-boring bits are recommended for drilling through hard metals but will damage thinner ones, so it's important to match the bit to the job.

Keyway cutting toolfor Lathe

... Tool, and Walter. Gregg Distributors is your Canadian source for Reamers ... Tools/Drilling-Accessories/drilling-reamers ...

The production of a keyway by the use of a milling machine is referred to as “keyway milling.” A “key” is a specific kind of component that is utilized in the process of mechanical transmission. Its primary function is to provide circumferential fixation between the shaft and the components that are mounted on the shaft in order to transmit torque. A few of the keys additionally have the capability of realizing the axial movement or fixing of the pieces on the shaft. The term “keyway” refers to the groove or slot that is machined for the purpose of placing the key. Keyways are typically cut along the axis of the cylindrical surface of a shaft. When a pulley is mounted on a shaft, the keyway on the pulley may make it impossible for the pulley to rotate on the shaft. The keyway can be classified as open type, semi-open type, or closed type depending on the degree of openness it has.

It is not possible to mill a through-slot using a vertical feed, thus you will need to use a carbide end mill to widen and mill the half-opened keyway. It is recommended to begin by drilling the hole, followed by milling it using an end mill that is narrower than the slot width, and then milling it to the desired width with a milling cutter that is either equal to the slot width or milling it with a shift cutter. Avoid down milling during expansion milling and always feel free to tighten any directions that aren’t being utilised.

by A Sayam · 2022 · Cited by 132 — The utilization of carbonaceous reinforcement-based polymer matrix composites in structural applications has become a hot topic in composite research.

Internalkeyway cutting tool

Wood-boring bits often have a brad point, which allows the user to center the bit and prevents the bit from wandering. Brad-point bits have extra-wide flutes that splay out at a 180-degree angle relative to the drilling direction; their purpose is to remove material quickly and hasten the job of making a hole. Masonry bits lack a brad point, but they also have flutes that splay out widely. The tip of a masonry bit is made from carbide steel, which allows it to withstand the rigors of penetrating hard materials such as concrete, brick and stone.

Portablekeywaycutter

The keyway milling cutter is capable of processing a wide variety of keyway varieties. When selecting the tool, you need to pay attention to the trial cutting to ensure that the mistake caused by the tool during the production process does not result in the keyway milling being made bigger than it should be. When milling, it is important to be aware of the distinction between down milling and up milling and to exercise caution so as not to cause a broach phenomenon during down milling. Markings may be drawn on the longitudinal and transverse tables of the machine tool in order to prevent punching from occurring during the cutting process. In conclusion, there are several varieties of keyways. It is required to do an analysis before to processing in order to determine which milling cutter and processing technique should be used for the various kinds of keyways. Utilization that is adaptable to enhance the effectiveness of processing and manufacturing.

Our mega tools are used for a variety of jobs but they have Atlantic Microtool quality in common. Select from our outstanding line-up of aluminum cutters, ...

Drill bits come in many shapes, but only two are appropriate for drilling metal. Forstner, spade, brad point and countersink bits can make drilling through wood and plastic faster and easier, but for metal, you need either a step bit, which works for soft metal, or a twist bit. Not all twist bits are for metal — some are exclusively for masonry, and some are only for wood or plastic.

Keyway Cuttingnear me

Indexable Milling. Home · Indexable Products · Milling · Finish Milling; MFF. MFF ... Molded Wiper Insert for High-Quality Surface Finish Utilizes Kyocera's ...

The MILWAUKEE® 4 1/4" HOLE DOZER with Carbide Teeth Hole Saw features a new 3 TPI design that offers fast cuts with the durability of a bi metal hole saw ...

Top highlights · Pipe Size: 1/2" MNPT Thread · Ferrule Size: 25.2mm, and fits 1/2" Tri-clamp · Made of stainless steel 304 for resistance to corrosion and high ...

Try the OmniLux range of coordinate measuring machines. Use the OmniLux family of optical CMMs to measure GD&T parameters faster, more accurately and without ...

Slot drill, quality two flutes, keyway milling cutter, and taper shank are the characteristics of this cutting tool. Milling cutters with taper shank keyways can be used to mill various faces, including step faces, convex faces, concave faces, and milling flat keyways. When cutting a flat keyway, taper shank keyway milling cutters are the most common tool utilised. This link consists of high-speed steel and has a taper shank keyway milling cutters with 2-blade configuration. There are several different round headed flat key seats that can be machined using taper shank keyway milling cutters. These cutters can also be used to mill grooves and bores.

Apr 29, 2022 — ... drill bit to grab and wander is less. I am talking about 120 degree spot drill used in conjunction with 118 degree drill bits. What's you ...

Bestkeyway cutting tool

The majority of the time, it is utilized in the process of machining keyways. The keyway milling cutter does not have a center hole on its end face, so it may be fed downward like a drill bit. This makes it possible to cut keyways. This indicates that it is able to drill holes with flat bottoms, which are often treated largely in grooves and keyways. Additionally, this indicates that it is versatile.

Some companies offer an all-purpose bit for quickly drilling through most materials, including light metal. This bit resembles a brad-point bit in that the flutes splay at a 180-degree angle, but the tip is smaller. Moreover, because these bits are coated with titanium nitride, they are gold.

In most cases, right-angle grooves and stepped components are what three-sided milling cutters are used for, but in other instances, open keyways may be milled using one of these tools as well. This kind of processing is analogous to how right-angled grooves and stepped pieces are manufactured. The main difference is that when you place the knife on the side, you need to take extra precautions not to scratch the workpiece. This is necessary to ensure that the surface quality of the product is not compromised. The milling process should also pay attention to the use of up-cut milling, and at the same time add coolant. The cooling should be adequate, and it should take place in a timely manner, in order to avoid the tool from being damaged by heat.

May 19, 2003 — Pearlite does have a response top tempering IF the temperature is high enough (more dramatic as you are approaching A1). Martensite spherodizes quicker, but ...

The choice of milling cutter, which is an essential step in the process of milling the keyway, has a direct impact on the precision of the keyway as well as the surface roughness of the keyway. When milling the closed keyway, it is common practice to employ an end mill in addition to a keyway milling cutter. Milling the open keyway, on the other hand, is often accomplished with a disc milling cutter. Milling various keyways requires a selection from the following types of milling cutters:

The majority of the work done with keyways and closed depressions require the use of a specific kind of CNC milling tool known as a keyway milling cutter. In order to neutralize the impact of radial cutting force, the keyway milling cutter is constructed with two cutting edges that are mirror images of each other and are symmetrical to one another. When milling a keyway, there is a certain set of requirements that must be satisfied in reference to the selection of a milling cutter. This decision has an immediate bearing on the precision of the keyway as well as its overall surface roughness. Milling an open keyway often requires the use of an end milling cutter in addition to a keyway milling cutter, while milling a closed keyway normally only requires the use of a disc milling cutter. When milling with an end mill, a hole should be bored at one end of the groove bottom with the same diameter as the milling cutter. This is done so that the hole will line up properly with the milling cutter. It is important that the depth of the hole and the depth of the groove be comparable to one another. The cutting instruments that are utilized throughout the milling process will have an impact, not only on the surface roughness, but also on the overall productivity.

Milling the closed slot requires the use of an end milling cutter, and the diameter of the tool you pick should be the same as or less than the width of the slot. When its stiffness is inadequate, the end milling cutter has a greater propensity to give under the force that is applied during milling. The cutter can crack if you apply an excessive amount of force to it. If you mill to the required size using the multilayer milling technique, the tool will be lifted above the expansion milling slot; as a result, it will not be possible for the tool to get trapped moving back and forth in the slot. When enlarging the slot, climbing milling should be avoided at all costs to prevent the workpiece from being damaged by gnawing

Material. Group. Examples. SFM · 3/16". 5mm ; Steels P · Mild - 1018. (.2-.3 Carbon). 500 ·.0011" .028mm ; Tool Steels. A2/D2/H13/P20. 280 ·.0009" .023mm ; Cast.

If you want an all-purpose bit that can make holes of different sizes, choose a cone-shaped step bit. The shape of the cone determines the range of hole diameters the bit will drill — each step displays the diameter of the hole it drills in inches or millimeters. Conventional HSS step bits are black, but the ones best for drilling metal are gold, because they are coated with titanium nitride for reduced friction and longer wear.

0086-813-8127573

0086-813-8127573