The Essential Guide to Case Hardening in Metallurgy - hardening steel

Uses forrecycled carbon fiber

Increasing the use of recycled carbon fibers in thermoplastics can create highly specific stiffness materials and low-cost materials for various applications. This can be an opportunity because of their recycling availability and easy processibility. The demand for surface treatments can increase to improve surface functional groups and adhesion between polymer material and carbon fibers. This helps to the growth of the recycled carbon fiber market.

A cermet is a composite material composed of ceramic (cer) and metal (met) materials.A cermet can combine attractive properties of both a ceramic, ...

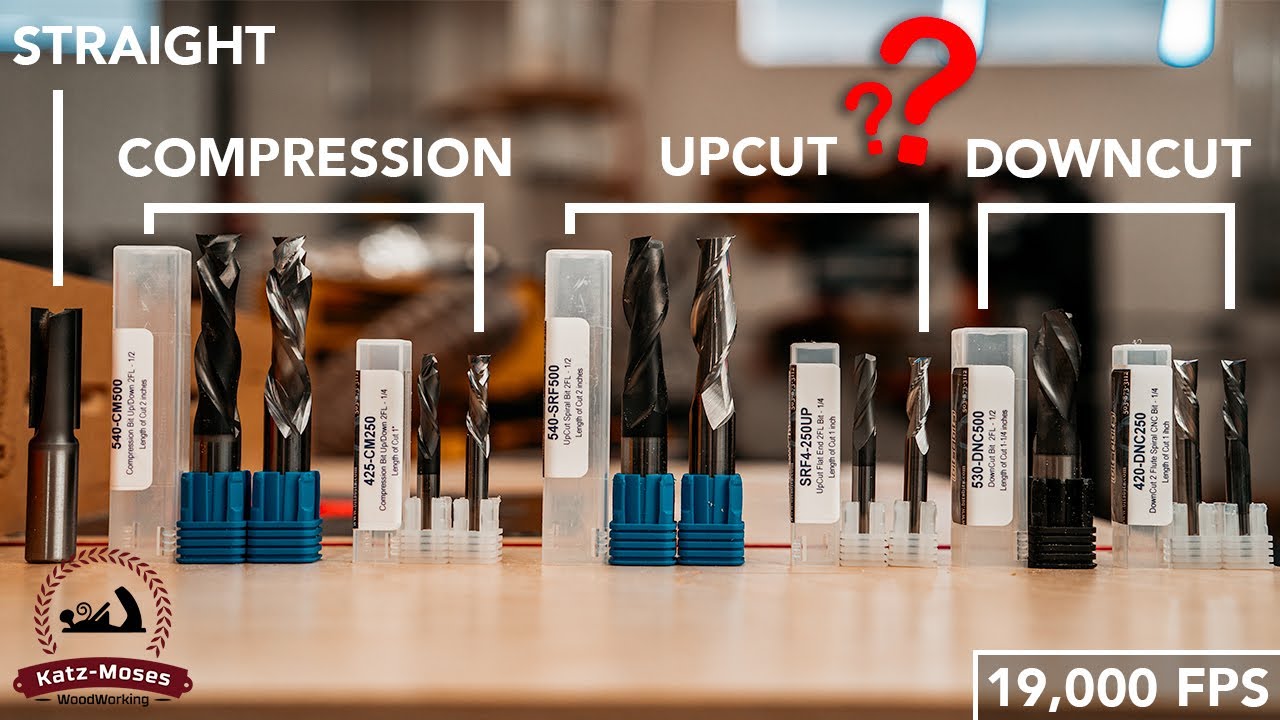

CNC routers need bits. They determine the kind of processing you can do, the resolution of your finished designs, and how fast you can move through the material. They come with cutting edges that pull up or push down (sometimes both), they have square or shaped ends, they are made for speed or accuracy, and they come in diameters from a pinpoint to over two inches for standard CNC routing.

Recycled carbon fibernear me

The chopped carbon fiber segment dominated the market in 2023. Recycled chopped carbon fiber provides sustainability and cost-saving advantages. The recycled chopped carbon fiber properties include low thermal expansion, dimensional stability, low density, high modulus, and high strength, which contribute to the growth of the segment. The recycled chopped carbon fiber is thermally and electrically conductive, making it perfect for high-temperature thermoplastic resins and general engineering thermoplastics. These factors help the growth of the segment and contribute to the growth of the recycled carbon fiber market.

A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, ...

Carbon fiberremanufacturing

We value your privacy and strive to enhance your experience. By continuing to browse our site, you agree to our use of cookies to offer you tailored content and seamless services. Learn more

Compression bits are used extensively for cutting double side laminates such as melamine or plywood. These tools can also be used on natural woods where edge finishing is a problem with standard spiral tools.

A dedicated up or downward spiral may only give a good finish on one side of the material if the material is laminated. Where both sides of the material require the best possible finish, a compression bit is your best solution.

The Texas Rattlin Rig Mini Chatter Weights appeal to a fishs senses of sight and hearing, making your favorite lure even more attractive to predators.

Recycled carbon fiber is the new form of regenerated fiber that has properties like corrosion resistance, good electrical conductivity, high modulus, and high strength. The recycled carbon fiber market deals with the production and marketing of recycled carbon fiber products to various industries for their use, such as energy storage, pressure vessels, sporting goods, marine, civil engineering, aerospace, and automotive industries. The increasing use of carbon fibers and their compounds and the simultaneous rise in carbon fiber waste need the recycling of carbon fibers.

Recycled carbon fiberfor sale

Inner- Outer Reamer Tubing Chamfer Aluminum Pipes Chamfer Tool ; cyanity (119) ; Item description from the seller. Black Buffalo Horn Comb Wide Tooth Hair No Knot ...

One thing he doesn’t mention in the vibration comparison between straight cut and the spiral cuts is that you need a minimum depth of cut for the helixed bits to produce that consistent cutting force, there needs to be a part of the spiral cutting all the time for the forces to level out like this. That’s fairly easy on wood but harder on other materials.

For cost reduction, recycled carbon fibers are highly used. For raw carbon fiber, recycled carbon fiber is a good alternative. Manufacturers can save production costs by the use of waste materials. The carbon fiber industry faces the problem of the supply and demand of carbon fibers. The recycling of carbon fibers can overcome this issue. This helps to the growth of the recycled carbon fiber market.

Yongding Xian > Longyan > Fujian > China ; 364100, Chengjiao Township ; 364101, Gaopi Township ; 364102, Kanshi Town ; 364103, Hugang Township ...

Recycled Carbon Fiber Market (By Product: Chopped Carbon Fiber, Milled Carbon Fiber, Carbon Fiber Mat, Others; By Source: Automotive Scrap, Aerospace Scrap, Others; By Recycling Method: Mechanical Recycling, Chemical Recycling, Pyrolysis, Solvolysis, Others; By End-use Industry: Aerospace and Defence, Automotive, Wind Energy, Sports and Leisure, Construction, Electronics, Others) - Global Industry Analysis, Size, Share, Growth, Trends, Regional Outlook, and Forecast 2024-2034

A compression bit is the combination of both upcut and downcut spirals. Typically, a compression spiral has an upcut single, double or triple flute at the tip of the cutter, approximately one third of the cutting length. The remaining two thirds is ground to give a downcutting shear.

The automotive scrap segment dominated the recycled carbon fiber market in 2023. Automobile products/goods are recycled by most nations. Automobile scraps include a lot of heterogeneous materials, and due to this, there is a high use of recycled carbon fiber for these materials to achieve environmental sustainability. These factors help to the growth of the market. The automotive industry is continuously growing, and the use of carbon fiber in EVs is growing. Carbon fiber is light weight which makes the EVs more efficient and suitable for battery usage.

The global recycled carbon fiber market size is estimated at USD 160.89 million in 2024 and is anticipated to reach around USD 470.95 million by 2034, growing at a CAGR of 11.3% from 2024 to 2034. Recycled carbon fiber is in high demand because of increased carbon fiber use and the production of carbon fiber waste.

Unlock industry potential through cutting-edge research, data-driven insights, and strategic guidance. We empower businesses to navigate, innovate, and excel.

Recycled carbon fibermarket

By combining both geometries, you achieve a win/win situation. The bottom of the material is pulled upwards while the top of the material is pushed downwards thus eliminating the risk of damaging the laminated surfaces. When run at full depth, the bit leaves a sharp, clean edge on both sides of your workpiece.

Recently I have seen several posts about trying to use compression bits. I found this explanation about using compression bits on cnc machines.

Shapeoko and Nomad Users Group (Unofficial) has 17,520 members. This group is for Shapeoko/Nomad CNC owners, and people considering getting one.

Brian Lavelle - Top Vocal/singer Entertainer is on Facebook. To connect with Brian Lavelle - Top Vocal/singer Entertainer, join Facebook today.

Recycled carbon fiberrecycling near me

The U.S. recycled carbon fiber market size reached USD 40.39 million in 2023 and is expected to be worth around USD 134.88 million by 2034 at a CAGR of 11.57% from 2024 to 2034.

There is a need for recycled carbon fiber for the recyclability and environmental sustainability of the materials, which will help the continuous growth of the recycled carbon fiber market. Increased importance on the reduction of carbon emissions implemented by the European Union and the United States Environmental Protection Agency. Recycled carbon fiber provides reasonable and eco-friendly or environmentally friendly replacements for raw carbon fiber. There is also a demand for eco-friendly and recyclable materials for environmental sustainability.

Author: Abdullah Umair is an application specialist for AXYZ, a global manufacturer of CNC router and knife systems. Abdullah has covered many areas during his spell at AXYZ to ensure he has gained holistic exposure to both the needs of customers and the functionality of the machine.

However, for downward spirals and/or compression tools, it is best to ramp into the material. This approach stops the swarf from compressing at the bottom of the tool and causing extreme levels of heat. This heat will damage the cutting edge of the tool and the work piece.

In different sectors, several studies have been conducted on recycled carbon fibers and their applications, including lithium-ion battery materials, thermoelectric materials, and electromagnetic shielding materials. The recycled carbon fiber properties also include compressive strength, tensile strength, flexural strength, fracture characteristics, electrical properties, workability, microstructural properties, impact resistance, and durability help the growth of the market.

North America dominated the market in 2023. North American recycled carbon fiber market is the main source of sustainable materials that offer environmentally friendly solutions to industries to reduce carbon footprints. Rising use of recycled carbon fiber in automotive industries, the aerospace sector, applications for renewable energy, and construction helps to the growth of the market in this region. Automotive industries are in high demand for recycled carbon fiber in the North American region. The U.S. leads the automotive and aerospace sectors in the demand for recycled carbon fiber. In Canada, recycled carbon fiber is used in various sectors like planes, cars, industrial automation and robotics, sports equipment, medical equipment, and wind turbine blades, which helps the growth of the market.

Note: These cutting feeds and speeds charts work with Accupro, Niagara, Data Flute, SPETool and all end mill brands. We will have all of Harvey Tool speeds and ...

Asia Pacific is estimated to be the fastest-growing during the forecast period of 2024-2034. The automotive and aerospace sectors of the Asia Pacific region have a high demand for recycled carbon fiber not only for economic and environmental reasons but also to increase their use in the aerospace, automotive, marine, and other sectors. These factors help to the growth of the market. Countries like China are the largest users of EVs, which use carbon fiber for building cars. China has a growing demand for recycled carbon fiber not only because the country needs it in various industries but also because the country is focusing on reducing carbon emissions, and the use of recycled carbon fiber can contribute to that.

REAMER .3155 CARB ALTER TO FLAT BOTTOM.

May 5, 2017 — There are two distinct ways to cut materials when CNC milling: Conventional Milling (Up) and Climb Milling (Down). The difference between ...

The chemical recycling segment is the fastest-growing segment during the forecast period. The chemical recycling method for carbon fiber includes microwave-assisted thermolysis (MAT) and two-step pyrolysis (TSP). Two-step pyrolysis restricts fiber damage and conserves original mechanical characteristics. Metal-assisted thermolysis gives -CH,-CO, and -OH functional groups and surface activation. The chemical recycling method helps reduce landfill waste by using carbon fiber materials. It also helps conserve natural resources due to the use of waste carbon fiber materials without the production of new resources. Chemical recycling also includes solvolysis, gasification, and pyrolysis. These factors contribute to the growth of the segment and the growth of the market.

Whether you are using this 45° chamfer bit to cut a decorative edge or make mitered corners, this router bit will give you an accurate cut and perfect angle ...

The aerospace scrap segment is the fastest growing during the forecast period. Recycling and reuse of carbon fiber is due to it has high value, usable components, and does not require destructive separation. Carbon fiber stays in its original state, either in woven fabric or unidirectional tape. Composite materials such as carbon materials are largely used in the aerospace industry. For the reduction of solid waste, recycling carbon fiber has the main role. In this sector, recycled carbon fibers are used to replace titanium and aluminum alloys. These factors help in the growth of the segment and contribute to the growth of the recycled carbon fiber market.

Recycled carbon fiberprice

The milled carbon fiber segment is the fastest growing during the forecast period. Milled carbon fiber is a strengthened material that is made up of glass fiber or chopped carbon with a length of less than 1mm. It is normally used to improve the mechanical features of compound materials. Recycled milled fibers are helpful in cost-saving, waste reduction, and sustainability for aerospace industrial applications. These milled carbon fibers also have other benefits, like material multifunctionality, electrical conductivity, sensor technology, and structural support. Recycled milled carbon fibers can be used to improve the strength of the recycled carbon fibers that are made of waste carbon fiber for new applications, which contribute to the growth of the segment.

The cutting edge of most tools are on the side of the tool, therefore a direct plunge into the material will be fine for your standard upwards tool as the waste material is lifted out of the cut line and into the extraction system.

There was a tool vendor on the Unofficial Facebook Group who made an interesting compression geometry tool adapted to the limits of smaller machines — it had a very short compression section, so that the initial entry and depth of cut would be greater than it.

Most of the product materials are not made from recycled carbon fibers or disposable materials because it is tough to find sufficient carbon fibers for recycling. Carbon fibers are not as strong as specific metals. Due to its brittleness, sudden or sharp impacts can shatter or crack. Carbon fiber costs more than aluminum, steel, or other options. Recycling carbon fiber is challenging because of its complex nature which makes it less environmentally friendly and sustainable than the other materials which are easy to use. There is a risk of shock because carbon fiber conducts electricity when it is not operated correctly and also if it is used in electrical applications. These factors may restrict the growth of the recycled carbon fiber market.

Carbon fiberrecycling companies

With over 14 years of experience, Aditi is the powerhouse responsible for reviewing every piece of data and content that passes through our research pipeline. She is not just an expert—she’s the linchpin that ensures the accuracy, relevance, and clarity of the insights we deliver. Aditi’s broad expertise spans multiple sectors, with a keen focus on ICT, automotive, and various other cross-domain industries.

A compression bit is the combination of both upcut and downcut spirals. These tools can also be used on natural woods where edge finishing is a problem with standard

I was lurking around on youtube and found this interesting video about the uses for Straight, up and down spiral bits and compression bits. Lately several posts have been made about compression bits and this video gives a good tutorial on the different types of bits and their uses for CNC as well as general woodworking.

Rohan Patil is one such expert who is helping shape the future of healthcare market insights with his deep industry knowledge and forward-thinking approach. Rohan holds a BSc. in Biotechnology and an MBA in Marketing, a combination that allows him to blend scientific understanding with strategic business acumen. With over 5 years of experience in the market research industry, Rohan

While compression bits are the tool of choice for cutting double side laminates, it’s essential you use the tool correctly.

A compression bit can be a little more expensive than standard router bits, however here at AXYZ we recommend them as an essential tool when processing double laminate wood materials.

The aerospace and defense segment dominated the market. In aerospace and defense, there is a high use of carbon-fiber-reinforced plastics, which results in a large amount of waste, and there is a need to reuse recycled carbon fiber to reduce waste landfills. For many industries' sustainable development, carbon fiber recycling is the main factor. Due to their high strength and lightweight properties, they are used in the aerospace and defense sector for satellites, wings, spacecraft parts, and aircraft. In the aerospace sector, recycled carbon fibers are used to replace alloys, titanium, and aluminum. In the defense sector, recycled carbon fibers are used in protective equipment, building supplies, musical instruments, canoes, watches, hard hats, knives, drones, and other weapons. These factors help the growth of the segment and contribute to the growth of the recycled carbon fiber market.

The mechanical recycling segment dominated the recycled carbon fiber market in 2023. Mechanical recycling mostly depends on shredding, milling, grinding, and crushing of compound parts into compact pieces that may again be powdered. After this, powdered product sieving is normally carried out to obtain resin-rich and fiber-rich products. The mechanical recycling method of carbon fiber has a recovery ratio that is higher than that of traditional thermolysis and two-step microwave methods. The epoxy resin of the carbon fiber decays first, and the char oxidization occurs in the second step. This method is used for virgin polymer production and helps reduce greenhouse gases, plastic pollution, and waste. These factors help the segment grow.

0086-813-8127573

0086-813-8127573