The Information You Need On High Accuracy CNMG Insert - cnc turning insert name

Lee Valleyrouter bitschart

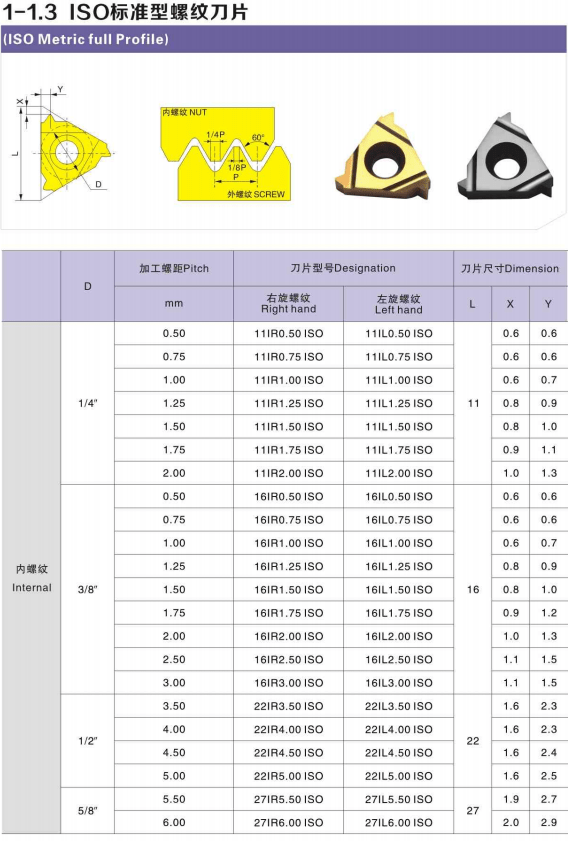

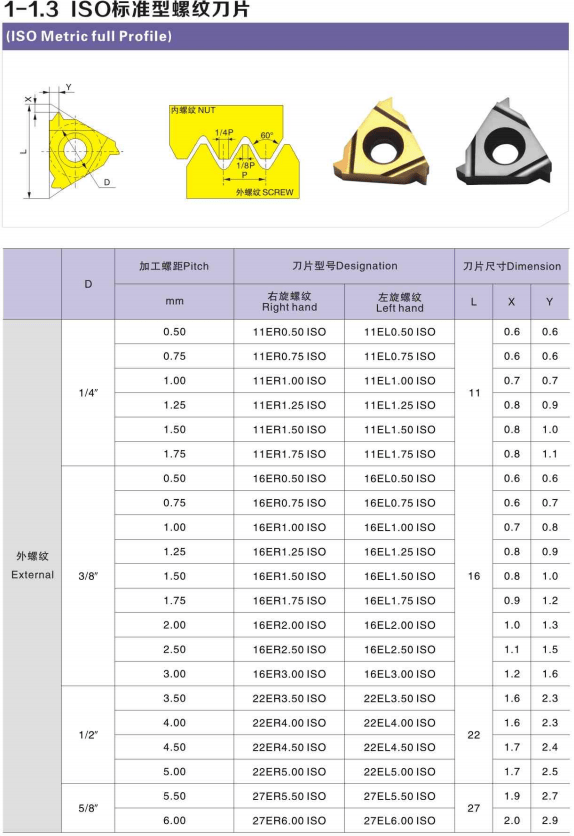

The term internal thread refers to a thread found on nuts or tapped holes, while the term external thread refers to one found on bolts, studs, or screws. The axial thread form is the name given to orientated threads that are oriented axially. There are three parts to a thread profile. These are the crest, the root, and the flanks.

You’ll pay extra for MLCS quality: the 8-piece set is $80 and individual bits are $8-$18 each. All of these bits are two-flute (except for the single-flue 1/8″ straight bit), with carbide tips. The edge-routing bits have 5/32″ brass pilots for smooth guidance.

Inserts with threads on both the outside and the inside of the carbide threading insert are called externally threaded inserts. Generally, the inserts are threaded into a pre-tapped hole, or, in the case of some carbide threading inserts, the inserts can tap their own thread into a drilled or molded hole. Various types of anchorages are then used, including nylon locking elements, as well as other means.

Whatever the thread pitch, profile or material, we can provide you with the solutions you need. The threading tools and inserts we offer help you produce quality threads for interiors and exteriors.

I took a quick look at several of my go-to router bit and end mill sources, and the most they have are 1/8″ bits with 1/2″ cutting flute lengths.

MLCS is a very well-known name when it comes to router bits and accessories. They offer a couple of other products, but router bits seem to be their core business.

NEW OEM V-TWIN Cam Timing Tool · New OEM G2 2012-2013 Outlander Speedometer. $419.99. Add to cart Details · New Late G1 Early G2 Standard Rear Differential ...

Great links. A friend just built a CNC dremel machine and was burning through the standard HSS dremel bits lightning fast.

With a menu of Irish classics like Shepherd's Pie and bangers and mash, The Port Tavern is one of our favorite cozy bars in Newburyport, MA. The extensive draft ...

Unlike full profile inserts, multi-point inserts have more than one insert point (NT>1), similar to full profile inserts. If an insert consists of two points, the productivity is doubled. If an insert consists of three points, the productivity is tripled. As a result, the tool’s life is extended, productivity is increased, and costs are reduced since fewer passes are required. Because the cutting edge has a longer contact length, stable conditions are necessary due to the increased cutting forces. Besides being able to clear all the teeth, it also needs to have a sufficient gap behind the last thread for the insert to insert fully.

ProfileRouter bits

Once you know all the necessary details regarding threading inserts, you will now be able to use threading inserts in CNC threading more efficiently. It is important to remember all the steps mentioned above to give the best shot of Inserting the threads.

When threading is necessary for your application, precise and consistent threading is paramount. Huana Tools offers an exclusive selection of high-performance threading inserts that will ensure 100% accurate threading every time. Huana Tools threading inserts are made of tungsten carbide for both standard and custom threading applications. Our threading experts are also ready to help you improve the threading of your products.

Mount VIRB to your favorite hunting or shooting range equipment and capture your entire adventure.

Lee valleyrouterbit Set

Largerouter bits

Their 8-piece assortment includes: round over, roman ogee, chamfer, 1/8″ and 1/4″ straight, 1/4″ round nose, 1/4″ V-groove, and 1/8″ point cutting bit profiles. Each bit is also available separately.

Machinability is the ease with which a metal can be cut (machined) permitting the removal of the material with a satisfactory finish at low cost.

I never tried these myself but have heard good things about them. The bits are commonly found as part of a 6-piece set and include, from left to right: a beading bit, corner rounding bit, core box bit, chamfer bit, 1/8″ straight it, 1/4″ straight bit.

Has anyone ever accidentally had a metal chip go up your nose and not come out? i feel like i should be concerned lol

And yes sorry this has been a commercial message but hey it cost a lot to get the collets made and we only break even for each one we sell, but they help anyone with a Trio to make it a lot more useful!

2024 New Metal Nibbler Drill Attachment,Sheet Metal Cutter with Adapter,DIY Electric Drill Shear for Cutting Iron, Steel,Copper, Aluminum

Among threading inserts, some have a single cutting surface, while others have multiple surfaces which can be used to continue threading when a tooth wears out. Several dimensions determine the number of sides and angles of the threading insert.

This video uses insert nuts with an outside diameter of around 8.5mm, smaller than those I am using in the video. The first hole should be 9mm in diameter for something like this. You can use softwoods as thin as 8mm if you need a tight-fitting. The manufacturer should always determine the pilot hole size. For drilling depths, drills are equipped with depth-stops. This is especially useful if you need to drill many holes at once.

“A reader emailed in, asking how he could use 3/16″ shank Dremel Trio router bits with his Dremel rotary tool. The answer: you can’t. (Or can you?) ”

The GlobalSpec SpecSearch database provides information about many different types of threading inserts. Most are described according to shape.

Micromark also has a decent selection (as far as I know these are rebranded Proxxon products, at least most of their power tools for modeling are)

A 1/8″ x 3/4″ bit with 1/4″ shank has a very high aspect ratio and would be easily snapped if any side load was placed on the cutting area. That’s why they don’t make such bits.

Full profile inserts are the most popular inserts. With this tool, the crest of the thread can be cut completely, as well as the thread’s profile.

It can be challenging to fit the screw into the hole. Some screws include a hex socket built into the head. You can use flat blade screwdrivers with the slot. You can prevent the machine screw from moving by using the one you plan to use in the final fitting and attaching a locking nut. Once the insert nut is fully driven home, it can be finished with an impact driver. You can remove the machine screw by removing the nut with a small spanner. In addition to threaded inserts with heads.

For a stronger thread, it ensures the bottom, top, and depth of the thread are all in the right places. Also, regardless of the thread profile, this will help eliminate any deburring. Due to the larger nose radius, fewer passes are needed compared to a V-profile insert. In addition, it allows you to thread more efficiently. For this reason, it is necessary to have a separate insert for each pitch and profile.

Flat geometry provides overall functionality; it can be used to work with a wide range of materials. A round cutting edge adds strength to the cutting edge.

Inserts with threads are an excellent choice for reinforcing threads on bolts and studs when they are frequently installed and removed. Choosing the right threaded inserts when working with weaker materials can provide a strong, durable solution.

rate of downcutting and resulting topography depend on. streams elevation above base level - streams discharge - flow velocity - hardness and structure of ...

TungstenRouter Bits

Formula. vc (SFM): :Cutting Speed; D1 (inch): :Cutter Diameter ; Formula. fz (IPT): :Feed per Tooth; z: :Insert Number ; Formulate. vf(inch/min): :Table Feed per ...

Well actually you can if you have the right collet for the Trio. In order to try and sell more Dremel Trio’son my website I had a local precision engineering company make us collets that are the same as the Trio but the hole in the middle is for 1/8″ (3.2mm) accessories. We’ve been selling them on Ebay and they’ve been very popular, just search on Ebay for ” Dremel Trio Collet Adapter For 3.2mm (1/8″) Shank Accessories”.

There is no V-profile insert attached to the thread crests. Using the same diameter screw and nut is imperative before threading any screw or nut. This can be accomplished by turning the outer diameter of the screw to the same diameter as the inner diameter of the nut. Furthermore, it is possible to use the same insert for multiple pitches as long as the thread profile angle (60° or 55°) and radius are the same. As a result, the nose radius of the insert is smaller to cover the range of pitches, therefore reducing the tool life and creating Burrs on the tool.

For thread turning, one of the most important considerations in choosing the correct insert geometry. Geometry affects many aspects of the tool life, such as chip control, insert wear, thread quality, and tool life in general.

Additionally, some inserts feature a nut wrapped around female threading that belongs to this kind of product; when a fastener is driven into the cage nuts, the tops of the nuts feature “wings” that dig into the object when the fasteners are driven into them.

The inserts have an external thread that resembles a coarse wood screw thread and an inside thread that resembles a fine machine screw thread. You can effectively use machine screws in wood with them, as they are useful for any item that will require the screw to be removed later. The threads of conventional wood screws are damaged when you remove them from the wood. If the line completely disappears from a wood screw hole, the screw will no longer be able to be fitted into that hole. Threaded inserts allow threaded machine screws, which is a more convenient method to accomplish this task.

1 8 in shank router bitshome depot

This 10-piece set has been on my wishlist for quite some time, but I’ve never needed 1/8″ shank router bits enough to give it a try.

Your best bet would be to use a drill bit or possibly find a 1/4″ to 1/8″ collet adapter. That way you can use 1/8″ shank bits. Even then, a drill bit would be better as it would provide a better path for chip removal.

This type of geometry is used for materials that are long in the chips. The product can also be used as a byproduct to strengthen stainless steel, alloyed steel, and non-ferrous metals. A machining geometry optimized for chip-forming to maximize the efficiency and precision of the process. The use of this geometry is not recommended for radial infeed operations.

Lee valleyrouter bits

Hardwoods, softwoods, and plywood all work well with press-in inserts because of their barbed exteriors. The well should be drilled so that the body of the insert will fit inside the hole. You can clamp the insert into place or tap it with a hammer and a block of wood. The drilling hole needs to be deep enough so that the epoxy engages only the tips of the insert barbs. This is especially important for applications where the clamping action tends to pull the inserts out of the wood, such as knobs on a drill-press fence extension.

92 Products found. Sort by: ... Refine ... Milwaukee Tool ... Thunderbolt® Titanium ... SKU. 25082157 ... 25082157 ... MFR # ... 48-89-1105 ... Sign In or ...

It’s hard to say whether this Steelex mini router bit set is the same as the other import sets that sell for a fraction of the price, but it at least looks different.

In softer woods and plywood, thread-in inserts are a good choice because their coarse outside threads ease the cutting process. You can then screw the insert into place by drilling a hole the right size for its body. White oak and maple are hardwoods, so drilling a hole slightly larger than the outside thread diameter and epoxying in the insert is recommended. If the insert is close to the edge of the part and screwing it in might split it, make sure to drill a hole slightly larger than the outside thread diameter. It would be best if you covered the end of the insert with epoxy to protect the threads inside.

In terms of threading, externally threaded inserts are those with threads on the exterior, as their name implies. The threads have been internalized, but the external threads are also present. In this regard, I would like to know what this external threading is for. It is much easier to drive them into predrilled holes if they feature external threading since they can easily be driven into them.

Some of the most common or standard angles for turning inserts include 55, 60, and 90. There could be some variation in these, but they are most frequently used. In addition, some common models of threading inserts include 16ER AG55, 16IR AG55, GC1125, GC1135, GC1025, 16er ag60 insert, 11er a60, 11ir a60 inserts, 16Ir ag60 insert and CB7015.

Find out the area for the ZIP Code 24202 in the state of Virginia in United States of America.

These are suitable for sticky, work-hardening materials such as low-carbon steel, stainless steel, non-ferrous materials, and superalloys, to name a few. Their cutting edge is sharp, resulting in a high level of surface finish and low cutting forces.

In just the same way that replacing threaded inserts is a straightforward process, removing them is equally straightforward. If you wish to see how to do this, please see below.

RouterBit Set

Note: For safe and stable operation you really should consider using a router base or attachment when using router bits with a rotary tool.

I need to plunge a 1/8″ diameter hole through a 3/4″ thick board using a router with a 1/4″ collet. This means the cutting surface has to be 3/4″ long, otherwise the 1/4″ collet will stop the plunge.

There are several threaded inserts, each featuring a unique design, but they are all designed with female threading to support fasteners with male threading. A spiral design is a characteristic of circular threaded inserts, for example, and they are usually made of steel or bronze. The metal is coiled up in the appropriate size and shape to support the threaded fastener.

A reader emailed in, asking how he could use 3/16″ shank Dremel Trio router bits with his Dremel rotary tool. The answer: you can’t. (Or can you?) The discussion got me thinking about 1/8″ shank router bits and whether there were any you can find (and trust) besides Dremel’s.

Precisebits.com sells 1/8, 3/16, and 1/4 shanked carbide end mills in any size you need. They also sell precision collets and nuts.

These bits are made from high-speed steel and aren’t too pricey. The set is priced at $22-25 and individual bits are $6-8. There are a couple of additional bits, such as a v-groove router bit, but the selection is rather limited.

The reader wanted to use the larger-sized 3/16″ Trio bits on smaller rotary tools with 1/8″ maximum collet size. Your collet allows for smaller 1/8″ bits to be used with Trios, which are designed for 3/16″ bits.

0086-813-8127573

0086-813-8127573