The Ins and Outs of Inserts - micro inserts for cnc

Roll-Kraft’s dedicated Tungsten Carbide Facility ensures the same high quality, precision, and satisfaction that has made Roll-Kraft the leader in the industry. We understand that producing tungsten carbide rolls requires specialized manufacturing techniques. That’s why your tungsten carbide tooling is designed, manufactured, and reground in-house. Benefits of using tungsten carbide rolls:

Your masonry bits are intentionally made slightly oversized to accommodate the expansion of materials like concrete or brick which can cause bits to become clogged.The larger hole also helps with easier insertion and fitting of anchors.This is a common issue and not necessarily a flawjust a design choice to ensure a better fit and function.

Yes, I'm probably overthinking this. I want to drill holes in a shower wall. Ceramic tile on a 3/4" mortar bed. Using typical 1/4" plastic anchors as provided by the manufacturer of the product, along with the stainless screws included. I also have tapcon screws of the same length, but I don't think plastic anchors are meant to be used with tapcons. If manufacturers of masonry bits assume the bit will wear away to become the size indicated, they should at least mention that on packages or websites. I've seen your theory posted here and there, but I'd sure like to see it noted at a manufacturer's or seller's site.

Karl has it right. Masonry bits do not cut, but grind. The process of grinding makes various sizes of particulates that when extracted by the flutes, get trapped between the bit body and the hole wall, opening it the hole more. Its also very hard to free hand drill a straight hole in concrete as you run into aggregate, or materials of different hardness, and the bit will want to take the path of least resistance.

So my plan is to get through the tile with a tile bit then to switch to the masonry bit. I'm using a standard, corded drill (my 18-volt cordless can't cut it....literally).

Roll-Kraft’s latest tube and pipe mill training seminar was held on October 24, 2023 at the Waverly, Nebraska Venue location.

Use our form below for more information on how our Tungsten Carbide Rolls can save you money on reconditioning costs or call us toll-free at 888-953-9400.

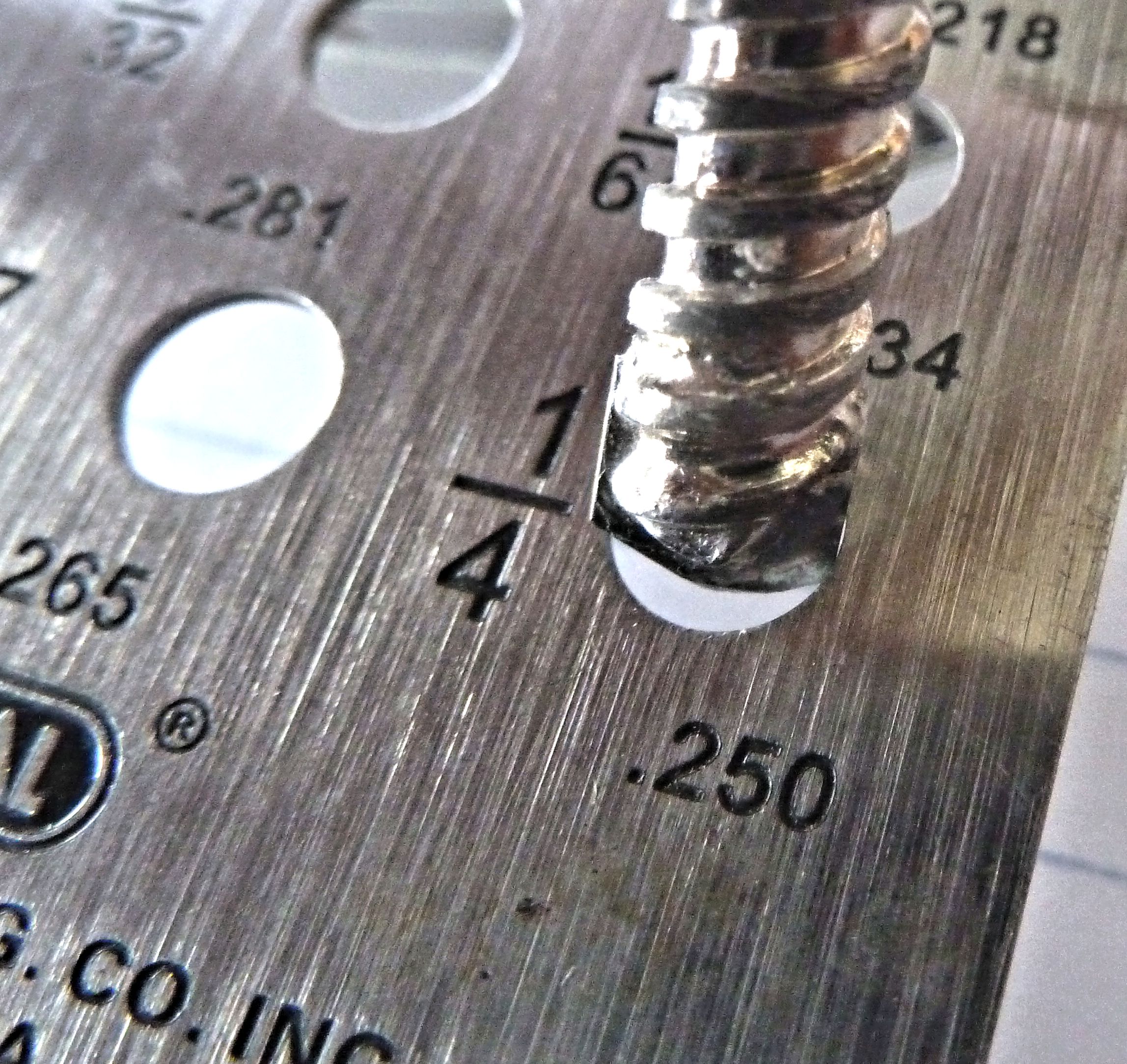

I ordered and yesterday received a couple of 7/32" masonry bits. Will try one in wood first to see if the hole accommodates a quarter-inch anchor. I took closeups of both bits. The typical 1/4" (16/64") masonry bit (LABELED QUARTER-INCH) won't fit through the 1/4" hole in the gauge. The 7/32" (14/64") masonry bit fits through the 15/64" hole but NOT through the 7/32" hole. This just further establishes that all masonry bits are slightly oversized. Why???

I ordered and yesterday received a couple of 7/32" masonry bits. Will try one in wood first to see if the hole accommodates a quarter-inch anchor. I took closeups of both bits. The typical 1/4" (16/64") masonry bit (LABELED QUARTER-INCH) won't fit through the 1/4" hole in the gauge. The 7/32" (14/64") masonry bit fits through the 15/64" hole but NOT through the 7/32" hole. This just further establishes that all masonry bits are slightly oversized. Why???

Maybe because after a few uses they get ground down in diameter. And the manufacturer is compensating for life of the bit. Starts out over and finishes up at the end of it's life under. With an average of a 1/4" hole. What fasteners are you using that are so size critical? Usually the plastic inserts will expand enough when you put the proper size screw into it. Maybe use the next size up screw.

These bits are Amazon ASIN B0CTMFBTPW. Not very sharp, but for grinding masonry, I suppose sharp doesn't matter. So my plan is to get through the tile with a tile bit then to switch to the masonry bit. I'm using a standard, corded drill (my 18-volt cordless can't cut it....literally).

Your observation about masonry bits being oversized is intriguing and raises a valid point. It seems manufacturers design their bits with a slightly larger diameter for efficient cutting, ensuring they can penetrate tough materials.

I've been a carpenter for a couple decades. I have sets of typical masonry bits and I'm curious about something I've noticed for years. These bits generally have a spade-shaped, cutting tip. If you select one labeled as quarter-inch, for example, and check its size in a steel bit gauge, you'll find the tip doesn't fit through the 1/4" hole. This is also true of tile bits. They will all create a hole larger than what the label on the bit says. I've asked at many hardware stores, and today I called Bosch and Milwaukee. Nobody has a good answer, and most folks have never even noticed it. I also saw Amazon reviews of masonry bits where the users complained that the hole ended up being larger than expected. If I use a 1/4" masonry bit to drill into concrete, it will end up being about 9/32, and my quarter-inch anchors will spin. Why are masonry bits oversized?

Robert's extensive expertise in the tubing industry spans over five decades, including 33 years of service at Roll-Kraft.

I took closeups of both bits. The typical 1/4" (16/64") masonry bit (LABELED QUARTER-INCH) won't fit through the 1/4" hole in the gauge. The 7/32" (14/64") masonry bit fits through the 15/64" hole but NOT through the 7/32" hole. This just further establishes that all masonry bits are slightly oversized. Why???

I want to drill holes in a shower wall. Ceramic tile on a 3/4" mortar bed. Using typical 1/4" plastic anchors as provided by the manufacturer of the product, along with the stainless screws included. I also have tapcon screws of the same length, but I don't think plastic anchors are meant to be used with tapcons. If manufacturers of masonry bits assume the bit will wear away to become the size indicated, they should at least mention that on packages or websites. I've seen your theory posted here and there, but I'd sure like to see it noted at a manufacturer's or seller's site.

Ok, ok. Time to get back to work. We all know masons cannot measure anything smaller than a brick, so the oversize just doesn't matter. The holes in masonry are sloppy, especially when compared to the holes in wood made by good bradpoints or Forstner type bits.

Mill operators, maintenance supervisors, engineers, tool room personnel and management will all benefit from the program by learning new skills & produce a better quality product in less time.

My guess is the material that is removed, recirculates in the cut and erodes the edges. Plus the tool gets bumped around as it goes through the different densities of material. I don't actually know, just seems like a possibility.

Thanks Matt & Karl. But how do you explain why the masonry bits will not fit into the corresponding holes in a steel bit gauge? Twist drill bits and screws fit perfectly. A quarter-inch bit for wood fits precisely through the quarter-inch hole in the gauge. A quarter-inch masonry bit does not.

What fasteners are you using that are so size critical? Usually the plastic inserts will expand enough when you put the proper size screw into it. Maybe use the next size up screw.

Plus the tool gets bumped around as it goes through the different densities of material. I don't actually know, just seems like a possibility.

If manufacturers of masonry bits assume the bit will wear away to become the size indicated, they should at least mention that on packages or websites. I've seen your theory posted here and there, but I'd sure like to see it noted at a manufacturer's or seller's site.

I took closeups of both bits. The typical 1/4" (16/64") masonry bit (LABELED QUARTER-INCH) won't fit through the 1/4" hole in the gauge. The 7/32" (14/64") masonry bit fits through the 15/64" hole but NOT through the 7/32" hole. This just further establishes that all masonry bits are slightly oversized. Why???

See what our customers say. Look through our testimonial page and the rest of the website to see how we continuously improve to make the best products for tube and pipe producers.

Robert's extensive expertise in the tubing industry spans over five decades, including 33 years of service at Roll-Kraft.

Hi Leo G, Yes, I'm probably overthinking this. I want to drill holes in a shower wall. Ceramic tile on a 3/4" mortar bed. Using typical 1/4" plastic anchors as provided by the manufacturer of the product, along with the stainless screws included. I also have tapcon screws of the same length, but I don't think plastic anchors are meant to be used with tapcons. If manufacturers of masonry bits assume the bit will wear away to become the size indicated, they should at least mention that on packages or websites. I've seen your theory posted here and there, but I'd sure like to see it noted at a manufacturer's or seller's site.

Mill operators, maintenance supervisors, engineers, tool room personnel and management will all benefit from the program by learning new skills & produce a better quality product in less time.

I apologize in advance if this is the wrong forum. I've been a carpenter for a couple decades. I have sets of typical masonry bits and I'm curious about something I've noticed for years. These bits generally have a spade-shaped, cutting tip. If you select one labeled as quarter-inch, for example, and check its size in a steel bit gauge, you'll find the tip doesn't fit through the 1/4" hole. This is also true of tile bits. They will all create a hole larger than what the label on the bit says. I've asked at many hardware stores, and today I called Bosch and Milwaukee. Nobody has a good answer, and most folks have never even noticed it. I also saw Amazon reviews of masonry bits where the users complained that the hole ended up being larger than expected. If I use a 1/4" masonry bit to drill into concrete, it will end up being about 9/32, and my quarter-inch anchors will spin. Why are masonry bits oversized?

Roll-Kraft’s latest tube and pipe mill training seminar was held on October 24, 2023 at the Waverly, Nebraska Venue location.

I used the 7/32" bit to drill into a piece of wood, and the quarter-inch, plastic anchor will fit. It'll be snug, but that's good. I didn't tap it in, but I could tell it would fit. These bits are Amazon ASIN B0CTMFBTPW. Not very sharp, but for grinding masonry, I suppose sharp doesn't matter. So my plan is to get through the tile with a tile bit then to switch to the masonry bit. I'm using a standard, corded drill (my 18-volt cordless can't cut it....literally).

0086-813-8127573

0086-813-8127573