The Manufacturing Process of Cemented Carbide Inserts - carbide insert manufacturing process

Along with steel, magnesium, and zinc, aluminum is one of the more popular metals for pressure die casting, and die-cast aluminum parts generally have an excellent surface finish and dimensional consistency.

Because aluminum chips easily, and because it is easy to shape, it can be cut quickly and accurately with CNC machine tools. This has some important consequences: firstly, the short timeframe of the machining job makes the process cheaper (because less labor is required from the machinist and less operating time is required from the machine itself); secondly, good machinability means less deformation of the part as the cutting tool goes through the workpiece. This can allow the machine to meet tighter tolerances (as low as ±0.025 mm) and leads to higher accuracy and repeatability. For more detailed information, check 7 ways to avoid part deformation in aluminum CNC machining.

End mills are most commonly designed with a square, corner radius, or ball profile. There are 90-degree angles on the corners of the flutes on a square profile end mill. By replacing the fragile sharp corner with a radius, corner radius profiles prolong tool life, adding strength and preventing chipping. Lastly, a ball profile is a profile that has flutes without a flat bottom and is rounded off at the end. An end mill with this style is considered to be the strongest. Unlike a sharp edge on a square profile end mill, an entire rounded cutting edge has no corners and removes the most likely failure point from the tool. Part requirements are often considered when choosing an end mill profile, such as square corners within a pocket, which require a square end mill. Consider using a tool with the most effective corner radius possible when designing your part. Corner radiuses are recommended whenever they are allowed by your application. Use a corner radius tool for rough corners, then finish with a square profile tool if square corners are necessary.

Pearl Milling company product array: buttermilk complete, original syrups, quick grits, yellow corn meal, on the go cup.

Your CNC machining tool has a coating of some kind that also affects the way it performs. A layer, such as titanium nitride can extend the tool’s lifetime, but the cost of the coating also increases. Some types of coatings can also reduce the amount of lubricant needed during the use of your tool since they make it less sticky.

The company describes the MU3-PD as a professional level, pneumatically controlled dovetail routing machine to rout a single dovetail keyway with each ...

Aluminum 6061, for example, is suited to hot forging with a closed die — a process commonly used to produce automotive and industrial components.

During rotation, the cutter’s cutting edges form a slot whose width is determined by its diameter. The smaller the cutter diameter, the greater the clearance within tight pockets, and the larger the tool, the greater the rigidity for jobs with high volumes. If the cutter diameter is selected incorrectly – either too large or too small – the job can’t be completed, or the final part won’t meet specifications.

One stumbling block is price. As a high-performance polymer, PEEK is one of the more expensive machinable thermoplastics, making it suitable only for machining projects where ubiquitous materials like aluminum are unusable.

Aluminum also offers specific advantages that simplify and improve the process of CNC machining. Unlike many other metals with similar material properties, aluminum offers excellent machinability: many of its grades can be effectively penetrated by cutting tools, chipping easily while being relatively easy to shape. Because of this, aluminum can be machined more than three times faster than iron or steel.

For CNC machining projects, aluminum is one of the most popular material choices due to its desirable physical properties. It is strong, which makes it ideal for mechanical parts, and its oxidized outer layer is resistant to corrosion from the elements. These benefits have made aluminum parts common across all industries, though they are particularly favored in the automotive, aerospace, healthcare and consumer electronics spheres.

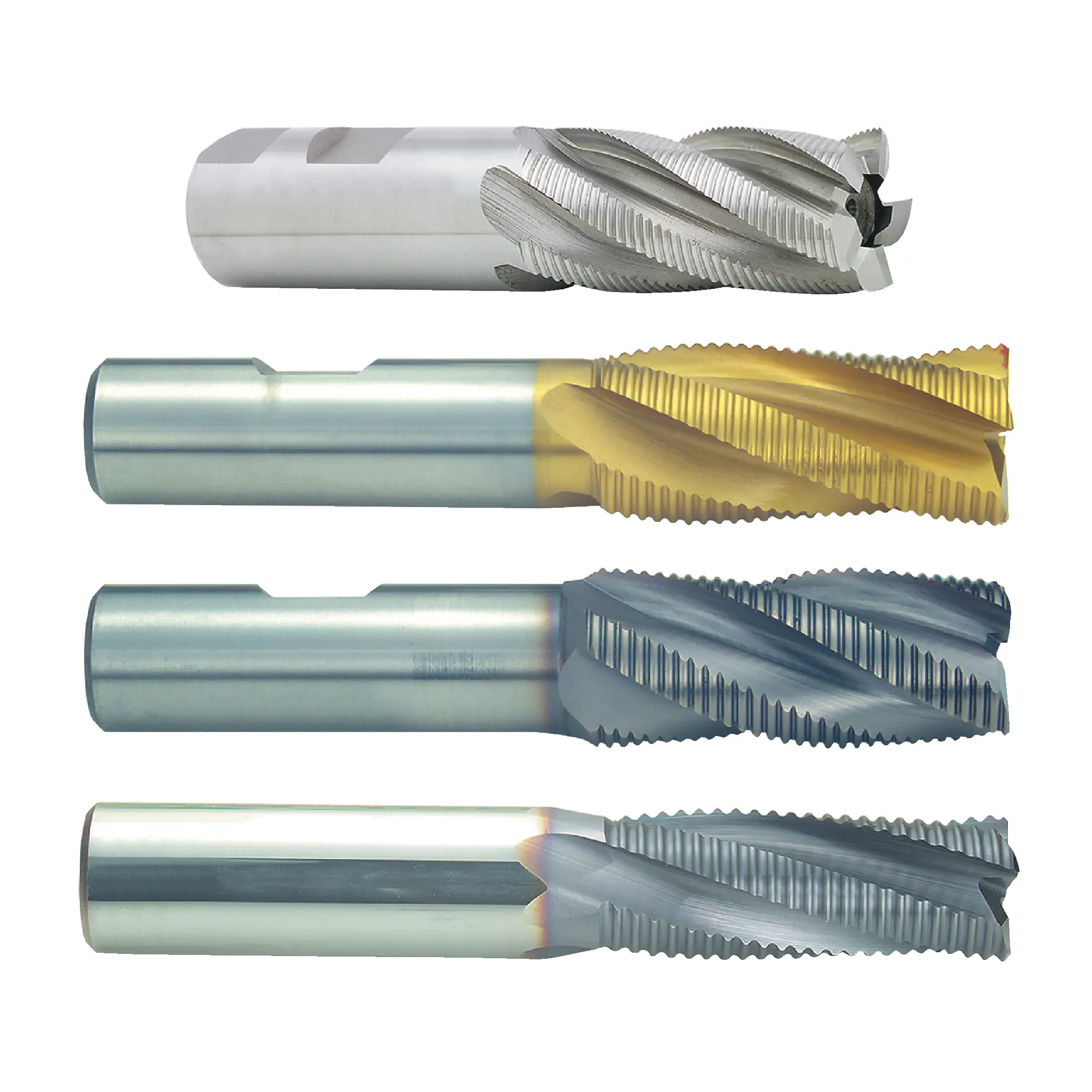

3/4roughing endmill

Are you new in the industry of milling? Or are you having a tough time recognizing the type of milling? You may need to consider working hard on your milling knowledge. Out of the most common milling tools, there are roughing end mill and finish end mill. They may seem similar to many people, or you can say to people who are beginners or who do not have knowledge about it. However, if you want to progress in the industry and know the clear distinction between both, I recommend you read the blog till the end. In this blog, we will thoroughly look at the difference between roughing end mill and a finishing end mill.

Importantly, anodizing makes it easier to add color to a machined aluminum part, since the anodized outer layer is highly porous. Dyes can find their way through the porous sections of the outer layer and are less likely to chip or flake since they are embedded within the tough exterior of the metal part.

An abrasive milling bit consists of channels called flutes. An angled milling bit’s feed rate is determined by how many flutes it has. The downside is you’ll end up with a significant milling bit, leaving fewer spaces for metal bits cut off from the workpiece due to a high number of flutes.

Roughing endmill feeds and speeds

This article explains some of the key advantages of aluminum CNC machining — reasons why it is one of our most widely requested prototyping and production processes — but also suggests machining alternatives to aluminum.

Though PEEK is harder to machine than the previous two thermoplastics, its high strength and thermal stability (resistant to temperatures up to 260°C) make it a genuine like-for-like alternative to aluminum. PEEK’s popularity for machining parts like valves, bearings, pumps, and nozzles testifies to its metal-like abilities.

CNC machining projects need not be limited to metals. In fact, several engineering thermoplastics can match or exceed some of the benefits of aluminum, depending on the application.

During an operation, the most extended contact length should determine the end mill’s cut size. Ensure that this only lasts as long as necessary. Minimizing overhang, increasing rigidity, and reducing chatter will be achieved by selecting the shortest tool. To avoid making long cuts in applications that require a depth greater than 5x the tool diameter, it may be best to explore necked reach options instead.

Another benefit of aluminum is its high recyclability, which makes it preferable for businesses seeking to minimize their environmental impact or for those who simply want to reduce material wastage and recoup some of their expenditure. Recyclable materials are particularly important in CNC machining, where there is a relatively large amount of waste material in the form of chips from the cutting tool.

One of the main reasons why engineers choose aluminum for their machined parts is because, quite simply, the material is easy to machine. While this would appear to be more of a benefit for the machinist manufacturing the part, it also has significant benefits for the business ordering the part, as well as the end-user that will eventually use it.

Unlike drill bits, End Mills rotate horizontally or laterally (side-to-side) rather than vertically. Material and surface finish should be considered when selecting endmills. Many types, sizes, and flute shapes are available. Using it, you can slot, profile, contour, counterbore, and ream. End mills are also used for engraving designs, cutting plastic, making molds, and making circuit boards, in addition to cutting precision parts.

Roughing end millsfor sale

... machines of various capacities for machining of spot face on the metal. Salient Features: DurableCorrosion ResistantAbrasion Resistant. Get Cutting Tools (a ...

Since aluminum is often favored for its excellent machinability, one viable plastic alternative is POM (Delrin), which is, like aluminum, highly suited to the machining process. POM has a low melting point but impressively high strength for a plastic.

Roughing Endmill for wood

Extrusion is the process of forcing molten material through an aperture in in a die, producing an elongated component with a continuous profile. While aluminum extrusion is an effective way of producing functional components with quality surface finishes and complex cross-sections, it is limited in scope, since those cross-sections must be consistent across the part.

Use the new Homes.com Neighborhood Search to find the neighborhood in ZIP Code 45235 to call your home. Discover neighborhoods by home price, crime, ...

As a result of their limited capabilities, regular carbon steel is usually not an option. Consequently, when it comes to getting the job done at a very reasonable price, HSS (high-speed steel) is the best choice. Furthermore, because of the rate at which it wears out, other options may be better if the product is used for an extended period.

One potential downside for machine shops? Magnesium chips are extremely flammable and are aggravated further by water, which means machinists must take caution while clearing debris.

The anodization process, which generally takes place after machining is completed, involves passing an electric current through the part in an electrolytic acid bath and results in a piece of aluminum that is more resistant to physical impact and corrosion.

Compared with standard end mills, roughing end mills remove much more metal, including large amounts, quickly and efficiently. When used to remove stock from low to medium carbon steel or alloy steel before finishing, coarse tooth end mills remove large chips from heavy cuts, deep slots, and rapid stock removal. When cutting high-temperature alloys and stainless steel, fine tooth roughing end mills remove less material but apply pressure to many more teeth, ensuring longer tool life and a smoother finish. Metal chips break into smaller segments due to scallops on the outside diameter of these mills. Cutting pressures are therefore lower at a given radial depth. When large amounts of material need to be removed, they are used mainly to rough mill it off. AlTiN or ZrN PVD coating is often applied to carbide, cobalt, and HSS substrates. In terms of pitch, they are available in coarse, medium, and fine varieties. Long, extra long, and stub versions are available. Since the milled materials differ widely, helix angles and flute configurations also vary. They come in a wide variety of diameter sizes from 1/8″ to 3″.

POM is an electrical insulator, making it suitable for parts like electronic enclosures. It is also suitable for mechanical parts. However, given its radically different insulating behavior compared to aluminum, it should only be used as a like-for-like replacement in situations where thermal and electrical conductivity is of negligible importance.

Bestroughing end mills

Machining titanium is a suitable alternative to aluminum when lightweight is a primary concern and, importantly, when the manufacturing budget has some flexibility.

However, while machining steels are engineered for improved machinability, aluminum remains the more machinable of the two materials. Steels are also heavier and have a higher hardness than aluminum, which may or may not be desirable depending on the application.

If aluminum remains the preferred material choice for a project, there are ways to combine CNC machining with other manufacturing processes in order to create more complex, higher-performing aluminum parts. Doing so can maximize the functionality of aluminum while reaping the benefits of multiple production processes.

Roughing endmill for aluminum

Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion

When you need a drill press for precise hole drilling or a hammer drill ... small projects. The maximum speed of power drills is measured in revolutions ...

Investment casting is a metal casting process that uses wax patterns to create metal parts. Like other casting processes, it produces parts with an excellent surface finish and high dimensional accuracy.

CNC machined aluminum parts can be useful for electrical components due to their electrical conductivity. Though not as conductive as copper, pure aluminum has an electrical conductivity of about 37.7 million siemens per meter at room temperature. Alloys may have lower conductivities, but aluminum materials are significantly more conductive than, for example, stainless steel.

Titanium may be used as a like-for-like replacement for aluminum since its primary advantage is an exceptional strength-to-weight ratio — also one of the main benefits of aluminum. Titanium has a similar weight to aluminum but is almost twice as strong. Like aluminum, it is also highly resistant to corrosion.

Different aluminum grades differ greatly in their resistance to corrosion — the degree to which they can withstand oxidization and chemical damage. Fortunately, some of the most popular grades for CNC machining are the most resistant. 6061, for example, offers excellent corrosion resistance, as do other alloys on the lower end of the strength spectrum. (Strong aluminum alloys may be less resistant to corrosion due to the presence of alloyed copper.)

ABS is commonly used as an injection molding material and, as of recent years, a 3D printing filament. But while ABS has very little in common with aluminum, it remains a versatile and lightweight material for CNC machining, offering above-average impact strength.

In addition to delivering excellent chip evacuation, helix four- and five-fluted routers have a multi-layer AlCrN coating to provide extended tool life. High feed rates and high speed are designed into the tool geometry. Besides having a radius on the corners, sizes are available in standard lengths and extended reach to accommodate milling in tight spaces.

Aluminum has desirable physical properties that make it ideal for both mechanical and aspect parts. Two of the most important are the metal’s high strength and its lightweight, both of which make the material favorable for critical parts such as those required in the aerospace and automotive industries. Aircraft fittings and automotive shafts are two examples of parts that can be successfully machined with aluminum.

The 118° angle is great for drilling metal, plastic, wood, ect. ... The split point self centers the drill bit keeping it from "Walking" across the surface.

A metal with a golden appearance, brass is a highly machinable metal available at a slightly higher price point than aluminum. It is commonly seen on parts such as valves and nozzles, as well as structural components, while its high machinability makes it suitable for high-volume orders.

The process also produces unique advantages: it can be used to create more intricate parts than would be possible with die casting, and parts emerge with no parting lines.

Combining aluminum extrusion and CNC machining is a great way to produce resilient parts with complex cross-sections and irregular geometries.

In addition to being an all-in-one manufacturing process, CNC machining can be used to refine or modify parts made using other machinery. Extrusion, casting and forging processes can each be complemented with the machining process to make better aluminum components.

Among them, cobalt-bearing HSS can be milled at even faster speeds than HSS without cobalt. As a result, most jobs can be performed with them, making them suitable for most applications.

In addition to being smooth as traditional end mills, finishing end mills have the advantage of rapidly removing large amounts of material. A two-step hogging/finishing process takes longer, while this process saves time. Resharpening tools will extend their life without modifying their shape. We offer a wide range of coatings, tool materials, and flute numbers to meet most machining requirements. One square end and a smooth outside diameter characterize a finishing end mill. There are a different number of flutes and helix angles on each helix. These tools are mainly used for side milling operations.

Steels and stainless steels are widely used materials in CNC machining. Because of their high strength, steels tend to be favored for high-stress applications and those that require strong welds. Steels are resistant to very high temperatures, and stainless steels can be heat treated to enhance their corrosion resistance.

The forged pieces of aluminum can be post-machined with a CNC machining center. This can be beneficial compared to machining alone since forged parts are generally stronger than fully cast or fully machined equivalents. However, post-machining allows for the creation of more complex geometries without wholly compromising the integrity of the part.

Nov 3, 2022 — One of the most important factors in choosing the right drill bits is the rotational speed. This is measured in revolutions per minute (RPM), ...

Surface finishing helps to improve surface finish, tolerance and minimize errors. Roughing is primarily used to remove excess material from a piece. In addition, roughing is conducted at a higher feed rate and a deeper cut depth. A roughing process also removes more material than a finishing process.

Die casting is a manufacturing process in which molten metal is forced into a mold cavity with high pressure. It is generally used when making parts in larger quantities since the required tool steel dies are expensive to make.

Other machinable plastics, most of which are highly dissimilar to aluminum, include PC, ABS+PC, PP, PS, PMMA (Acrylic), PAGF30, PCGF30, DHPE, HDPE, and PPS.

Like POM, PTFE (Teflon) is a highly machinable thermoplastic which is an excellent electrical insulator. Unlike POM, however, PTFE is also resistant to high temperatures (up to 260°C), making it a viable aluminum alternative for high-temperature applications.

Although not the most common machining material, the lightweight metal magnesium offers many of the benefits of common aluminum alloys. In fact, magnesium is one of the most machinable metals out there, making the machining process fast and efficient.

High-quality tools should be designed when milling at high speeds and temperatures (which can cause premature tool wear). Coatings should also resist oxidation at such high temperatures since oxygen becomes reactive. By combining fine-grade substrates with the coating, both toughness and hardness are simultaneously increased.

Before we delve into their importance and different types available, let's first understand these terms. What is the CNC Tool Holder? A tool ...

A rough cut is applied to impart a basic shape according to desired characteristics as a first step. It is not essential here to consider surface roughness; instead, removing the most significant amount of unwanted material from the surface is more important. In contrast, finishing passes are performed to improve surface quality, dimensional accuracy, and tolerance. Finish passes do not take into account stock removal rates.

Here are some potential machining alternatives to aluminum, with an emphasis on their differences and similarities to the popular silver-gray metal.

Roughing EndMill Set

These advantages can be combined with the advantages of CNC machining. By die casting aluminum components then adding further cuts using a machining center, it is possible to create parts with an exceptional finish and more complex geometries that would be possible using either process on its own.

However, different grades of aluminum serve different purposes. Because of their favorable strength-to-weight ratio, general-use grades like 6061 can be used for a wide variety of parts, while notably high-strength grades like 7075 may be preferred in aerospace and marine applications.

It will help you narrow down your end mill selection considerably if you know the material you are working with and its properties. Mechanical properties determine how a material behaves when machining and every material has unique characteristics. The machining strategy is different for plastic materials, and the tooling geometries differ from steel ones. Tool performance and longevity will improve by choosing tools with geometries suited to those unique characteristics.

Many machinable aluminum alloys are also suited to the age-old process of forging, which involves shaping metal through compressive force. (This often involves hitting the metal with a hammer.)

Roughing endmill vsendmill

A great deal of emphasis should also be placed on edge preparation. A homogeneous, deliberately rounded-off cutting edge prevents cracks from forming, minimizes wear, and ensures even abrasion. Various materials can be machined with milling cutters that possess these characteristics.

Gravity dies casting can be used instead of pressure die casting if reducing cost is more important than ensuring high precision or creating thin walls.

Choosing the right tool is essential when performing CNC machining, as it is a critical factor in the project’s success. The CNC machining needs of Huana Tools are more efficient than those of other companies. You must know which tool to use in each position since every position requires a different tool.

Our experience with CNC machining and fine detailing means we can produce a wide range of aluminum machined parts, from small and simple to large and complex.

SPECIFICATIONS · Drill Bit Size: 17/64 in · Length: Jobber · Material: High Speed Steel (HSS) · Surface treated for abrasion resistance and improved chip flow ...

Also, its high chemical resistance makes PTFE (Teflon) a popular machining material for parts that will be used in the food industry.

These advantages are reflected in the higher price point of titanium. Though the material is an excellent choice for parts like aircraft components and medical devices, its cost can be prohibitive.

Unless, of course, the part is modified after extrusion. Because aluminum extrusion tends to involve malleable, ductile and machinable aluminum grades like 6061 & 6063, the extruded parts can then be post-machined — cut in various ways using a CNC machining center.

Machined aluminum parts are especially popular in the consumer electronics industry, not just for strength and weight demands, but because of important aesthetic considerations. As well as being receptive to paints and tints, aluminum can be treated with anodization, a surface finishing procedure that thickens the protective and oxidized outer layer of the part.

It is the degree of roughness that determines the degree of demand placed on the inserts as well as the cutting angles. Surface finish is usually improved by using positive rake inserts when finishing machining. Some aspects of negative rake inserts make them most suitable for rough machinings, such as absorbing cutting forces, which makes higher cutting speeds possible.

Copper shares several material properties with aluminum. However, the superior electrical conductivity of copper can make it preferable for various electrical applications. While pure copper is difficult to machine, many copper alloys offer similar machinability to popular aluminum grades.

The surface quality produced by both the end mills is better if we compare that of the roughing and finishing process. Unlike roughing, finishing can provide high dimensional accuracy and close tolerance, whereas roughing cannot.

Almost every conventional machining process results in the appearance of scallop marks or feed marks due to the velocity of the feed. Roughness on the surface is caused by scallop marks similar to saw teeth. The feed rate is the only factor directly responsible for surface roughness other than tool geometry. The surface finish of a product can be negatively affected by a higher feed rate. A higher depth of cut also degrades surface finish and machining accuracy. As a result of rough cutting, more excellent feeds and deeper cuts are utilized, resulting in poor surface finishes. It also does not meet the requirements for close tolerances and high dimensional accuracy. By contrast, finish passes require very low feeds and shallow cut depths, improving finish, accuracy, and patience.

Businesses may seek alternatives to aluminum for CNC machining for any number of reasons. After all, the metal has a few weaknesses: its oxide coating can damage tooling, and it is generally more expensive than alternatives like steel, partly due to the high energy costs of aluminum production.

May 5, 2024 — The etching function of the tool is specially designed for use with HONA etching pads and is perfect for etching the nail plate with accurate ...

Concerning the properties mentioned above of such milling machine tools, cemented carbide is another step toward high-performance milling. The up-front costs are higher but more cost-effective in the long run.

Aluminum alloys are a common material used for investment casting, and the cast aluminum parts can be post-machined for refinement.

0086-813-8127573

0086-813-8127573