The Ultimate Guide to Carbide Drill Bits for Hardened Steel - drill bit for hardened steel bolt

This pneumatically controlled dovetail routing machine is the more automated version of the MU 3 and MU3-D models. Aside from the same attributes in terms of design and built quality, the machine features two pneumatic cylinders and a pneumatic foot pedal.

After the carbon fiber composite sheet has been cut, it is often necessary to smooth the carbon fiber to ensure success. This article shows the cutting process of carbon fiber composite sheets in comic form.

Wear a dust mask and goggles to avoid carbon fiber dust. Although carbon fiber dust is non-toxic, it can still irritate the eyes and lungs, so before cutting carbon fiber, you should always wear good protective gear and ventilate the area as much as possible to eliminate dust. A vacuum hose can also be set up near the workbench to pick up dust while cutting the carbon fiber.

Having a drop-down table works great because the carbon fiber dust can be sucked away as it is created using the built-in ventilation system. If there is no drop table, the carbon fiber must be cut on a flat table top. Use clips or a vise to hold the carbon fiber in place.

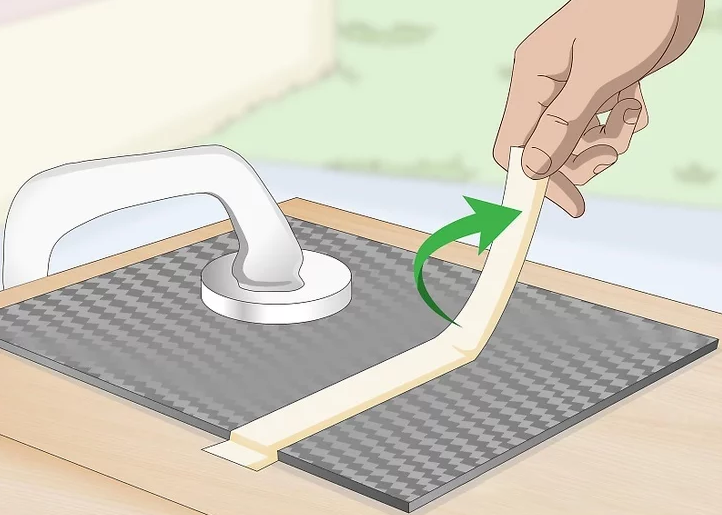

Carbon fiber sheets are mostly black, so ordinary pencil marks are difficult to show on carbon fiber. First, measure out the planned cut with a ruler, then lay down multiple strips of tape to form a border around the area to be cut. This works especially well for round surfaces such as carbon fiber tubes; marking tools such as silver permanent markers can also be used, which can be combined with tape for greater precision.

Professional level, pneumatically controlled dovetail routing machine to rout a single dovetail keyway with each machining cycle. Heavy cast aluminum construction with large, ergonomically shaped table surface, precision linear bearings, galvanized steel motor carriage with integrated motor fine adjustment.

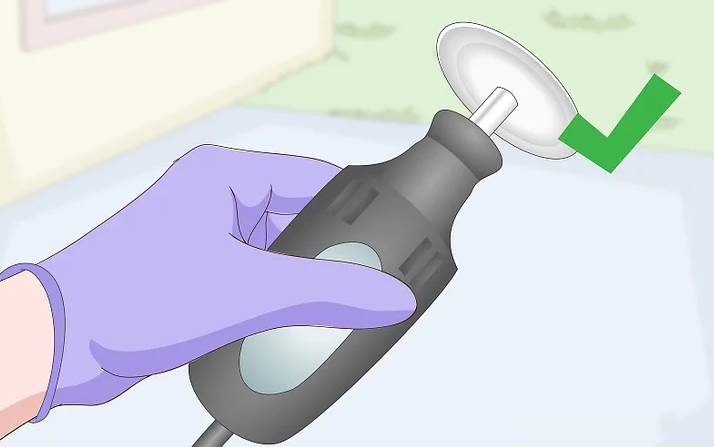

If the blade starts to overheat, the speed should be reduced. This usually occurs when the rotating tool has difficulty penetrating hard fibers, especially with ordinary metal wheels. Some signs of overheating are harsh squeals, loss of cutting power, burning smell or smoke. If you suspect that the tool is overheating, remove it from the carbon fiber and turn it off until cool.

It is best to choose a saw with a tungsten carbide grit style blade. The serrations are the biggest problem with cutting carbon fiber with a saw, blades with large teeth will break the carbon fiber, while blades with small teeth will clog the resin and wear out faster. Your best bet is a harder blade with finer teeth or no teeth at all, and designed to work with metal or carbon fiber, you can use jigsaws, saber saws, or even handsaws with tungsten carbide grit-type blades.

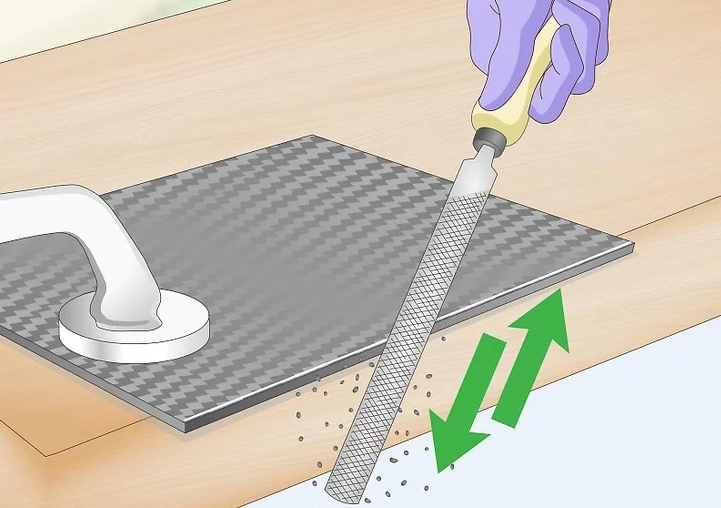

Use a metal file to remove excess material from the cut edges, when finished, the edges should look smooth and even; you can also use a block of sandpaper, such as a coarser 120 grit to grind off excess carbon fiber, while a finer 180 Rough surface to smooth the edges.

These Kodiak Cutting Tools four flute solid carbide chamfer mills are available in a range of angles for a variety of chamfering applications.

B & R CUSTOM MACHINING in Cambridge, reviews by real people. Yelp is a fun and easy way to find, recommend and talk about what's great and not so great in ...

Shipping Notice: Unless specified on the product, items are FOB Origin. It is the responsibility of a customer to pickup, either personally or by a contracted shipping agent, their product.

After the carbon fiber sheet is placed on the cutting surface, the rotating wheel is placed on it; when cutting, it can be cut directly along the guide lines traced on the carbon. Hold the saw on the side of the line closest to the part you want to discard. When the rotary tool is all the way through the carbon fiber, continue to move it along the part until the cut is complete.

SKU: HM-101060 Manufacturer: Hoffmann New w/ Factory Warranty From the Manufacturer: Professional level, pneumatically controlled dovetail routing machine to rout a single dovetail keyway with each machining cycle. Heavy cast aluminum construction with large, ergonomically shaped table surface, precision linear bearings, galvanized steel motor carriage with integrated motor fine adjustment. For Dovetail Key sizes W-0, W-1, W-2, W-3 (W-4 with optional larger motor) *Hoffmann MU3P in this listing is shown with optional table extensions GET PRICING

Smooth the cut with 180-grit sandpaper, briefly rubbing down the edge of the cut to level the cut, removing excess material around the guide lines you are following, also eliminating any sharp edges. When you're done, inspect the carbon fiber carefully for any unevenness and smooth it out.

We're constantly getting new listings. Let us know what you're looking for and we'll notify you when the equipment is available.

2022322 — Before you can drill a hole in metal, you need to find your center and start the hole. Without this you likely won't drill the hole exactly ...

- Power Supply: 120 volts - 7.4 Amps - Air Supply: 90 psi - approx. 0.1 cubic foot/cycle - Motor: 885 Watt motor with double front bearing - Motor speed: 35,000 rpm at idle - Collet size: 1/4" - Motor carriage guides: 20mm diameter guide rods, precision ground - Digital Display: dual liquid crystal display, 3/8" digit size, accurate to 0.004" - Operation: pneumatic - dual cylinder design - Max. height routing: 3 3/4" - 95mm / moulding 5 7/8" - 150mm - Dust collection port: 2" - 50mm diameter - Installed router bit: W-2, solid carbide - Available router bits: W-0, W-1, W-2, W-3 (W-4 with optional larger motor) - Dimensions W/D/H: 29 1/8" x 25 5/8" x 32 3/4" (without optional table extensions) - Weight: 70.4 lbs.

May 24, 2017 — While in the Thread Feature Property Manager, expand the Thread Options menu, check the new Multiple Start box, and toggle the number of starts ...

Position the blade 1/2 inch (1.3cm), since saw blades cause more chipping than rotating tools, try to position the blade a little further from the line if possible.

Hoffmann Dovetail Routing Machine, model MU 3-P, ready for operation, with air regulator installed, W-2 solid carbide router bit installed, standard 45 degree center fence plate, center line locator and square stop, motor fine adjustment, parts storage, toolkit and manual.

Choose from diamond or tungsten carbide cutters, or use a variety of common rotary tools to cut carbon fiber, including Dremel, pneumatic rotary, router or angle grinder. But no matter what you choose, make sure that the wheel or wheel listed is an abrasive or grit type. Smooth wheels and drums are less likely to seize or overheat than toothed wheels and drums. Any wheel or drum designed for cutting metal will work.

Comprehensive Introduction to China Hydraulic Shearing Machine.A pratical guide to beginners. Help you choose the right shears!

Apr 15, 2016 — So my calculation to determine the diameter to use in calculating rpm ... Then the formula becomes sfm/(0.262 inch) (diameter). Using the ...

One short stroke cylinder is used to clamp the material the instant the foot pedal is pressed, while a second, larger cylinder is used to move the router carriage up and down.

The Liberty Select Cycler is a peritoneal dialysis machine designed with the varying clinical and personal needs of your patient in mind. Learn more here.

Cut carbon fiber is usually very sharp, so be prepared with a pair of reinforced gloves. Plus, longer gloves stop carbon fiber dust from accumulating under your nails and between your hands. Wearing long sleeves can help protect the rest of your body, and if you plan to cut a lot of carbon fiber, wearing gloves will be very helpful. If carbon dust does accumulate on the skin, it may sting and the area should be rinsed immediately with cold water.

Due to the high strength properties of carbon fiber composites, carbon fiber composite sheets are sometimes difficult to cut. In general, using a rotary tool is an easy way to cut most pipes and flats quickly and cleanly; a saw blade is a better choice if you don’t need to be straight when cutting.

May 29, 2008 — I have been able to drill with HSS bits, but cobalt works much better especially with lowered speeds. I recently bought a cheap set from ...

The main benefits compared to the manual machines are faster and more comfortable operation, more consistent results due to set routing feed rates and the fact that both hands can remain on the material during the routing sequence. This is an important advantage when processing longer parts.

This is a Cold Rolled Steel, 2'' Diameter x 20' Round Bar. 1018 Round Cold Rolled Steel Bar is a low carbon, medium manganese steel that maintains close ...

Highlights: This pneumatically controlled dovetail routing machine is the more automated version of the MU 3 and MU3-D models. Aside from the same attributes in terms of design and built quality, the machine features two pneumatic cylinders and a pneumatic foot pedal. One short stroke cylinder is used to clamp the material the instant the foot pedal is pressed, while a second, larger cylinder is used to move the router carriage up and down. The main benefits compared to the manual machines are faster and more comfortable operation, more consistent results due to set routing feed rates and the fact that both hands can remain on the material during the routing sequence. This is an important advantage when processing longer parts. Standard Features: Hoffmann Dovetail Routing Machine, model MU 3-P, ready for operation, with air regulator installed, W-2 solid carbide router bit installed, standard 45 degree center fence plate, center line locator and square stop, motor fine adjustment, parts storage, toolkit and manual. Technical data: - Power Supply: 120 volts - 7.4 Amps - Air Supply: 90 psi - approx. 0.1 cubic foot/cycle - Motor: 885 Watt motor with double front bearing - Motor speed: 35,000 rpm at idle - Collet size: 1/4" - Motor carriage guides: 20mm diameter guide rods, precision ground - Digital Display: dual liquid crystal display, 3/8" digit size, accurate to 0.004" - Operation: pneumatic - dual cylinder design - Max. height routing: 3 3/4" - 95mm / moulding 5 7/8" - 150mm - Dust collection port: 2" - 50mm diameter - Installed router bit: W-2, solid carbide - Available router bits: W-0, W-1, W-2, W-3 (W-4 with optional larger motor) - Dimensions W/D/H: 29 1/8" x 25 5/8" x 32 3/4" (without optional table extensions) - Weight: 70.4 lbs. Warranty: One year on parts and workmanship.

All Milwaukee Grinding Wheels & Cut-Off Wheels can be shipped to you at home. ... Related Searches. grinding disc · metal cutting wheel · grinder blades · cut off ...

0086-813-8127573

0086-813-8127573