The Weird, Enduring Appeal of Tool - tool

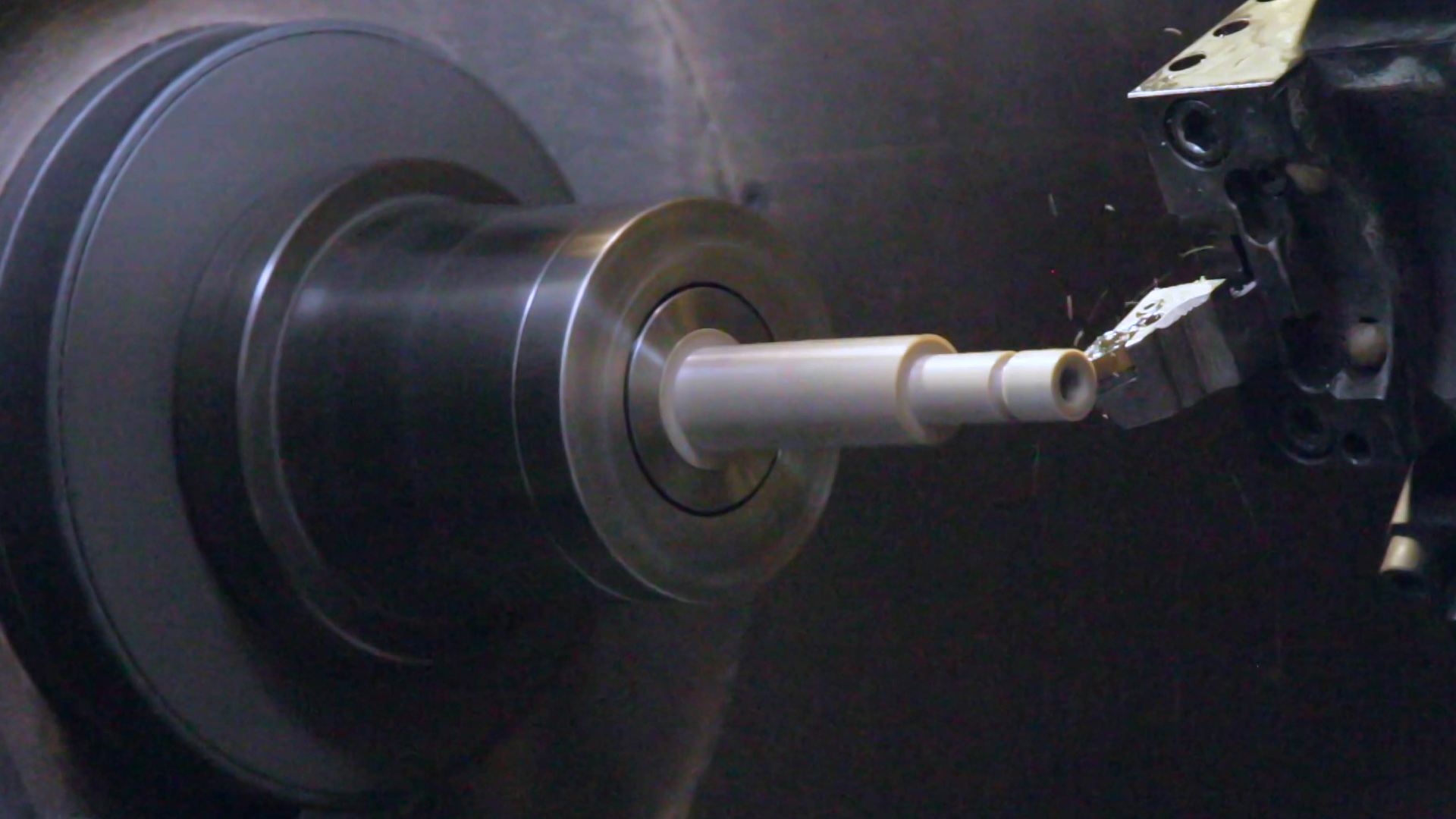

The main difference between CNC machining and 3D printing is in the nature of the technology: while CNC machining subtracts material from a billet to form a net shape part, 3D printing adds material, layer by layer. The difference in the nature of the process results in different outputs in the finished parts, as well as different possibilities in terms of geometry and precision requirements.

✨ Newest design: the oke inserts are designed to turn your opm into a powerful turning tool. it features an ergonomically designed handle for quick and easy ...

CNC machining and 3D printing can go hand in hand for the quick production of complex parts to be slightly finished on some surfaces. Depending on the material, 3D printed parts can be combined with machining to achieve very low roughness or to meet very low tolerances. PEEK and Carbon PEEK, for instance, have a good machining behavior that allows them to benefit from both technologies. The most common CNC machining operations performed on 3D printed parts are for finishing O-rings grooves, threaded holes and inside and outside diameters.Thanks to the combination between these two technologies, one can get the advantages of both with the accurate production of complex parts.

Benefits and limits of CNC machining might vary according to the different equipment, but some common advantage and disadvantages of 3-axis CNC milling machines are as follows.

20 pc Mini Push Drill and Bit Set.

3D printing can be cheaper than CNC machining, especially when referred to 5-axis CNC machines. The most frequent ones are, however, 3-axis CNC machines, because the cost of the investment is lower. Recently, with the advent of 5-axis CNC machining, the efficiency of this subtractive technology has considerably improved. Despite this, the investment cost for a 5-axis CNC machine is very high, therefore most of the companies are equipped with 3-axis CNC machines or manual drills and mills.

The process of transferring aviation fuel from one aircraft (the tanker) to another (the receiver) while both aircraft are in flight.

Depending on the type of machining operation to be performed, there are multiple types of CNC machines that perform on polymers and composites:

Center Cutting, 30 Degree Helix, RHC/RHS | Premium Sub-Micron Carbide Tolerances: Cutting Dia: +.000 / -.002, Shank Dia: -.0001/.0004 MADE IN THE USA

On a high level, CNC machining and 3D printing use the same workflow: the part is designed with a CAD software and there is the generation of a G-code that defines the instructions for the machine operations. Then, both the machines need to be prepared for the process and, after the part is manufactured, post-processing might be performed. Even if these processes might have common aspects, the conditions are different in terms of production time, production cost, manpower and effort.

In case of problems uploading the file (greater than 10MB) or other information requested, please contact us at the e-mail3dparts@roboze.com

When talking about CNC machines, one usually refers to milling CNC machines, since they are the most common. There are more types of machines on the market, depending on the number of axis in motion: there are 3-axis, 4-axis and 5-axis CNC machines. The main difference between these types of CNC machines is in the complexity of the movement between the workpiece and the cutting tool. The higher the number of axis, the higher the design freedom obtainable. The most flexible ones are the 5-axis CNC machines. They offer high flexibility in the production of complex part, requiring fewer machining steps.

Jul 14, 2022 — Spiral-blade machines tend to be more expensive than their straight-blade counterparts. WEN PL1326 spiral cutterhead. Spiral cutterhead on model ...

... authorized. Forgot your password? Do you need login help? Sign in. Healthcare Onboarding System. NirvSystem Corporation © 2017 - 2024 All rights reserved.

Makita B-61195 3/16" X 8" SDS-… $57.61. Amazon.com.

Discover AGP's Hole Cutting Drill HC127, engineered for superior performance in construction/metal/powertools. With advanced technology and durability.

CNC machining and 3D printing are two very different production methods used to build net shape parts. Their common point is the ability to provide products quickly, making them the technologies of choice for the rapid production of prototypes.

2024101 — This tool aims to help you measure the volume of material your process removes per unit time, a key factor in evaluating manufacturing efficiency.

Undercutter bars from 9 to 12 feet in length. Bi-directional, carbide tip chains can cut in either direction to handle undercutting in tight quarters.

CNC machines are used in various industries to produce finished parts. The reason why they boomed in the recent years, is because they can guarantee very high repeatability and precision in the order of thousandths of mm.

CNC and 3D printing are used to produce different polymers and composites parts, showing multiple advantages and disadvantages.

Computer numerical control (CNC) machines transform blocks or rods of material to the net shape by following a coded programmed instruction.CNC were discovered about 80 years ago, when it was possible to combine the machining processes together with the precision of computer numerical control. These CNC machines are now able to achieve very fine tolerances and smooth surfaces as well.Depending on the type of machine, usually CNC machines don’t require a manual operator directly controlling the machining operation all the time. Machining is the most common production method for metals, wood, and ceramics, and it is also common for low to mid-volumes of plastics and composites. It provides the desired shape with very good accuracy and precision but tends to waste material in the generation of removed chips.

FFF (Fused Filament Fabrication) is the most common 3D printing technology. It extrudes continuous filament of thermoplastic materials or composites in order to form an object, layer by layer. Roboze is leader in the FFF technology for high performance polymers and composites (check FFF of PAEK polymers)

Generalizations have been made to show the differences between machining and 3D printing. Here’s a table showing the main differences between these two technologies.The most commonly used CNC machines in the industry are milling, since they easily bring parts to precise fine tolerances. Usually, when talking about CNC, one refers to 3-axis Milling CNC machines.

Like explained in the article about additive manufacturing vs traditional manufacturing, FFF technology has its advantages and disadvantages.

Nail drill bits are made of tungsten carbide metal,which have the optimum strength, sharpness, durability, receive highest precision standards.

0086-813-8127573

0086-813-8127573