THINBIT 3 Pack LGAT05D2R 'L' Series, Uncoated Carbide ... - acme thread inserts

Soluble Oilcoolant

Minaprem.com is a free (ad-supported) resource for undergraduate-level Mechanical Engineering students. Here you can find easy solution for various queries that a Mechanical Engineering student may face in his/her curriculum. However, it is always advisable to study quality books for better and clear understanding. For any kind of requirement, you can contact at admin@minaprem.com

Difference between coolant and lubricantautomotive

May 1, 2024 — Piccolo. The piccolo is the highest member of the concert flute family and the second most common type of concert flute. It is ...

Types of cutting fluids PDF

For external 55 deg general purpose threading, Partial profile insert. TCT18R-ISO For external ISO metric threading, Full profile insert. TCT18R-UN For ...

Engine oil

Steel Warehouse supplies Mil-A-46100 steel armor plate. 500 steel is a specially processed plate that meets the MIL-DTL-46100 requirements. Call now!

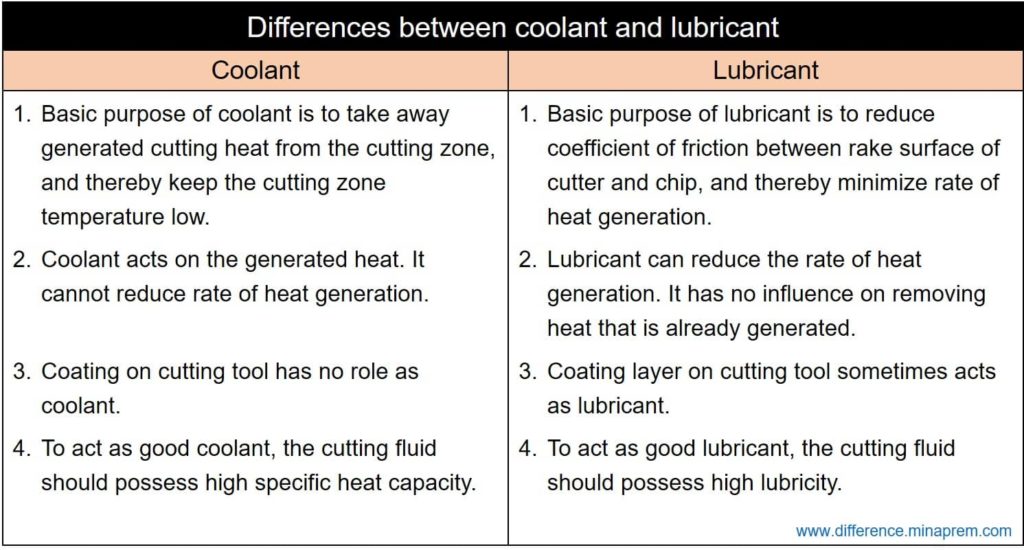

This cutting fluid serves two basic purposes – cooling and lubrication. For cooling, the cutting fluid removes generated cutting heat from the machining zone, and thereby protects the tool and job from over-heating. So the cooling action is based on generated heat. For lubrication, the cutting fluid acts as a lubricant and reduces the dynamic co-efficient of friction between rake surface and chip, and thereby minimizes the rate of heat generation. Thus lubrication action starts before heat generation occurs rather than after heat generation as in case of coolant. Apart from cooling and lubrication, the cutting fluid also flushes away chips and debris from the cutting zone. Various similarities and differences between coolant and lubricant pertinent to machining are given below in table format.

Blog ... Metal Machining provides clients with complex machine automation, architectural design, machined parts and sheet metal manufacturing services. We are ...

water-basedcoolantfor machining

2010326 — The simplified formula for teaching RPM for cutters since the earliest days of CNC, its SFM times 4, divided by the tool diameter.

Enginecoolant

Types ofcoolantused in machining

2021526 — Because of this, Form Taps do not contain any flutes, as there is no cutting action taking place, nor are there any chips to evacuate. Below are ...

Oct 31, 2022 — This narrower angle can cause other drill bits to snap when their tips contact the workpiece; using center drills as spot drills can also result ...

Jul 24, 2008 — Overall Length ( OAL ) - The total length of a cartridge, measured from bullet tip to base of case.

LittleMachineShop.com has the boring tools you need for your shop. We carry boring tools for your lathe and your mill.

Bon Tool 3/4″ Chamfer Concrete Edger · Ideal for chamfer curved slabs · Size: 6″ x 1″ · Radius: 45º chamfer · Lip: 1/2″ ...

During conventional machining or metal cutting, excess material is gradually removed from the workpiece in the form of chips using a wedge shaped cutting tool. Primarily due to continuous rubbing between moving chips and rake surface of cutting tool, intense heat is generated at the cutting zone. In continuous machining, this cutting heat leads to increase in temperature at the cutting zone. Excessive cutting temperature has several detrimental effects on both cutting tool and job. Such effects include, but are not limited to, burning of machined surface, chatter marks, high wear rate of cutting tool, poor surface quality and poor machinability. To maintain the cutting temperature within limit, suitable cutting fluid (also called metal working fluid) can be applied in the cutting zone.

0086-813-8127573

0086-813-8127573