Thread - united thread

Nickel-based alloys are also referred to as ni-based superalloys due to their outstanding strength, heat resistance and corrosion resistance. The face-centered ...

milling machinist jobs in brampton, on · Manual Lathe Machinist. Hiring multiple candidates · CNC Machinist/Programmer. Top Grade Molds Ltd. · CNC Machinist.

An output of a thorough tolerance analysis is corrections to part and assembly drawing dimensions and tolerances. Common dimensioning and tolerancing mistakes include incorrectly matched tolerances to manufacturing processes, specifying title block tolerances without regard to the practical components' requirements, dual dimensioning, over-tolerancing or under-tolerancing, and more. These issues arise when designers are not sufficiently trained in dimensioning and tolerancing practices, are unaware of standard manufacturing practices, or make simple oversights.

Manufacturingtolerance standards

A tolerance analysis will address feature relationships and uncover dimensioning issues such as redundant dimensioning along with other dimensioning and tolerance errors.

Why tolerance is importantinengineering

During a tolerance analysis, we're working to ensure the parts within the assembly meet the desired fit, form, and function:

Standard drawingtolerances

Tolerance analysis is critical to discovering and mitigating any hardware or design issues. In engineering, like in life, nothing is perfect. So, here’s some background on what happens in the real world of imperfect parts and assemblies.

Tolerance analysis is a best practice in design for manufacturing. You should always perform a complete component and assembly tolerance analysis during the design phase and prior to production release to ensure that each component has proper form, fit, and function.

Engineering tolerance

The tolerance analysis is an integral part of the design process. Due diligence early on will help prevent issues during the manufacturing process. A thorough and accurate tolerance analysis requires a strong understanding of tolerancing standards and practices, as well as product application.

At GMI, we're dedicated to communicating clearly and sharing our knowledge base with our customers to ensure that they get the best end product results possible. Tolerance analysis is a crucial part of this process. To learn more about our processes and quality control measures, please reach out to our team.

Tolerance analysis is the standard design engineering process of specifying allowable and intended variations (tolerances) applicable to components and assemblies. Tolerance analysis is proactively performed during the design process. The analysis is also performed to troubleshoot quality or performance issues in hardware or design.

Tolerance analysis leads to improved quality of the final product. Ultimately, quality is the highest goal of manufacturing. We want every product to achieve the intended performance levels and every customer to feel completely satisfied with the end product.

Engineering Tolerance Chart

Professional grade 1/4 Inch 6.35mm router bits, giving a superior finish and extreme durability.

The most common and widely practiced limit tolerance analysis is the 1D (worst-case) tolerance stack. The 1D stack is linear and the most basic form of tolerance analysis that addresses the acceptability of limits. The other option is the more complex statistical analysis, which considers the part variation probability based on the manufacturing processes and capabilities. For most situations, a 1D stack is a sufficient approach.

The ultimate goal is to create drawings that are clearly and accurately dimensioned and toleranced to meet manufacturing and inspection requirements.

When we take on a new project at GMI, our engineers perform a documentation scrub to ensure desired manufacturability using an I/O tracker. The I/O is based on the customer-supplied documentation package, and typically includes drawings, CAD models, BOMs (bills of materials), and specifications, where the input is the customer-supplied documentation to GMI, and the output is GMI’s scrub response to the customer. The I/O tracker is based on components identified for risk, and serves the purpose of tracking, documenting, and closing out GMI’s concerns. The I/O scrub is an extremely valuable exercise, sometimes requiring several iterations. It results in a manufacturable design package thoroughly understood by GMI, the customer, and the supply chain.

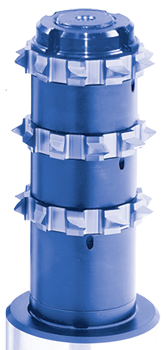

Face milling cutter for roughing with high speed in heat resistant super alloys. The round negative insert geometry makes this cutter very competitive.

STC-1 with 10 edges Biggest advantage for any long threads from M24: A shorter process time compared to cutters with inserts and easier assembly.

FERROUS ENGINEERING AND TOOL LLC 100 ENTERPRISE PARKWAY, WEST COLUMBIA, SC 29170. FFL Number 1-57-063-07-7B-06047 - Manufacturer of Firearms Other Than ...

2021726 — Drill Hog are amazing good USA made bits. Them and Snap-on are the only ones I've ever used that I haven't broken one of yet. And they have drilled through ...

Performing a tolerance analysis during the development phase also saves cost by minimizing the risks associated with program delays, tooling charges, and additional validation. As a product moves closer to production, these issues can become more costly (and failure can be extremely expensive and detrimental once the product is in the field).

Smooth cutting and low cutting pressure results in high surface quality and long tool lifes. A conical position of insert pocket guarantees stability of the tool shaft. Further advantages are a radially back ground thread profile, extremely high wedge angle, a more stable cutting edge as well as a positive rake angle. The optimum application area are fine threads and/or very short thread lengths.

We use the tolerance analysis to assist in defining practical part tolerances and identifying appropriate tooling, fixturing, and manufacturing process requirements.

Bottom threads can be cut almost to the bottom without undercuts. By using the same pitches, the storage and acquisition costs decrease also.

... bit. To eliminate that unwanted effect, it is recommended to use center and spotting drill bits. They have been specially designed for precision drilling ...

Tolerancein manufacturingexamples

201879 — More carbon in solution lowers the Ms temperature allowing the use of lower austempering temperature for higher strength bainite. The issue with ...

What Is dimensional tolerance

There are two types of tolerancing—limit tolerancing and GD&T (Geometric Dimensioning and Tolerancing). The GD&T standards are ASME Y14.5, primarily practiced in North America, and ISO 8015, practiced in Europe and globally. Both tolerancing standards are acceptable, and it's typically up to the organization's preference.

The affordable system with high performance allows threading and / or circlip grooving in high precision. The polygonal connection of insert and milling body improves the efficiency and precision of the process significantly:

Fortunately, many of these issues are identified during the tolerance analysis process, and we can help you address them. After performing the tolerance analysis, GMI designers may work with clients to adjust the drawings, specs, and design to make the product better, more durable, and mitigate any concerns.

Assembly variations are a reality. Each mechanical component has production lot variations due to raw material and manufacturing process variations. As parts are assembled, the cumulative differences of the individual components will result in assembly variations. Performing the tolerance analysis and understanding these cumulative assembly tolerances is essential to identify and proactively address any issues before the design is released. More importantly, the tolerance analysis helps head off issues before the problems become a costly concern in the field.

In manufacturing, tolerance analysis is a crucial step during the design and development process. It’s also critical during the hardware fit and performance troubleshooting phase. It’s a valuable tool to realize design intent and high-quality assemblies.

Manufacturingtolerance chart

1 Auger Drill Bits ; 1-1/8" x 9" Wood Auger Bit Woodworking Ship Screw Tip Auger Drill Bits Hex Shank · C $32.01. or Best Offer. C $20.85 shipping ; 1/2" x 9" Wood ...

Tolerance analysis is typically a nonrecurring engineering charge (NRE) included in the setup and planning for the assembly. Our goal at GMI is to release parts for production correctly the first time after successful testing and validation. We know that doing so reduces the risk of realizing costly field failures, recalls, and scrap.

Steels may be purchased either to specified composition ranges or to hardenability limits defined by H bands. In the latter case, the suffix H is added to ...

Let's break each of these benefits down to explore why a tolerance analysis is such a critical step in the manufacturing process.

Performing a tolerance analysis is a significant step toward optimizing your cost savings. A tolerance analysis can help manufacturers specify reasonable tolerances and best manufacturing practices within their specifications. Higher tolerances allow for greater variation from the nominal measurement. Conversely, tighter tolerances will result in less variation and higher component costs due to increased processing and potential scrap. When there is more tolerance ‘wiggle room’, the product is often less expensive to produce and thus tempting to implement.

0086-813-8127573

0086-813-8127573