Thread Cutting - Internal and External on a Myford ML10 ... - cutting threads

Woodmachinist salary

Bringing bespoke ideas and designs to reality in several woodworking disciplines, including CNC routing, turning, linear profile moulding, curved work, solid wood and panel machining.

The symmetrical art of woodturning is still in demand for traditional and modern designs. Whether replicating turned balusters for heritage properties, or making simple cylindrical legs for modern furniture, our turning equipment suits all aspects of this craft.

“Stay in touch, sign up for our newsletter and get the latest news from the Clive Durose group” Name Email* ProfessionArchitectInterior DesignerContractorCarpenterOtherN/A If other – please state here Test Form HiddenHidden form to give a value? Submit

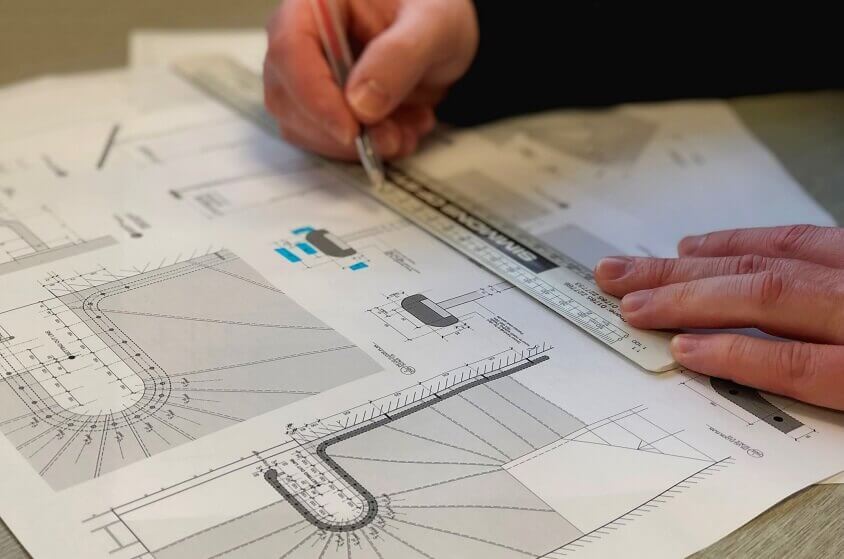

Making full use of our CAD and CAM software, our experts carefully draw, model, analyse and program each part. At each level of programming we aim to maintain accurate machining techniques to achieve the best possible surface finish with reduced wasted for eco-friendly production.

Wood machiningnear me

Timber is carbon neutral, a natural and renewable resource that suits many structural applications but has tremendous aesthetic appeal. Clive Durose brings out the best in wood with our knowledge and expertise.

Timber is carbon neutral, a natural and renewable resource that suits many structural applications but has tremendous aesthetic appeal. Clive Durose brings out the best in wood with our knowledge and expertise.

Woodmachinist job description

Making full use of our CAD and CAM software, our experts carefully draw, model, analyse and program each part. At each level of programming we aim to maintain accurate machining techniques to achieve the best possible surface finish with reduced wasted for eco-friendly production.

WoodMachinist jobs near me

Our timber is selected from environmentally responsible sources. We take every step to minimise the impact of our operations on the environment.

From one-off bespoke projects to production runs of machined components, we can be your solution for the manufacture of timber components.

Our timber is selected from environmentally responsible sources. We take every step to minimise the impact of our operations on the environment.

Our highly skilled CAD technicians’ use leading industrial design software to generate 3D models of each product prior to production; thoroughly testing each component through virtual simulation to ensure precise accuracy, resulting in unrivalled excellence in all that we make.

We have CNC lathes for precision and repetition, fluting and twisting equipment to produce intricate design features and more recently we invested in an 8 axis CNC machine for the most demanding of components.

Where design input is needed, our heritage of craftsmanship and fine woodworking is there to support our clients in creating ergonomic and distinctive components.

0086-813-8127573

0086-813-8127573