Thread Milling Tools | SmiCut - The Master of Threading - thread mill tools

The design and engineering team at Crowley Tool Company has decades of combined experience in a broad spectrum of manufacturing fields, including:

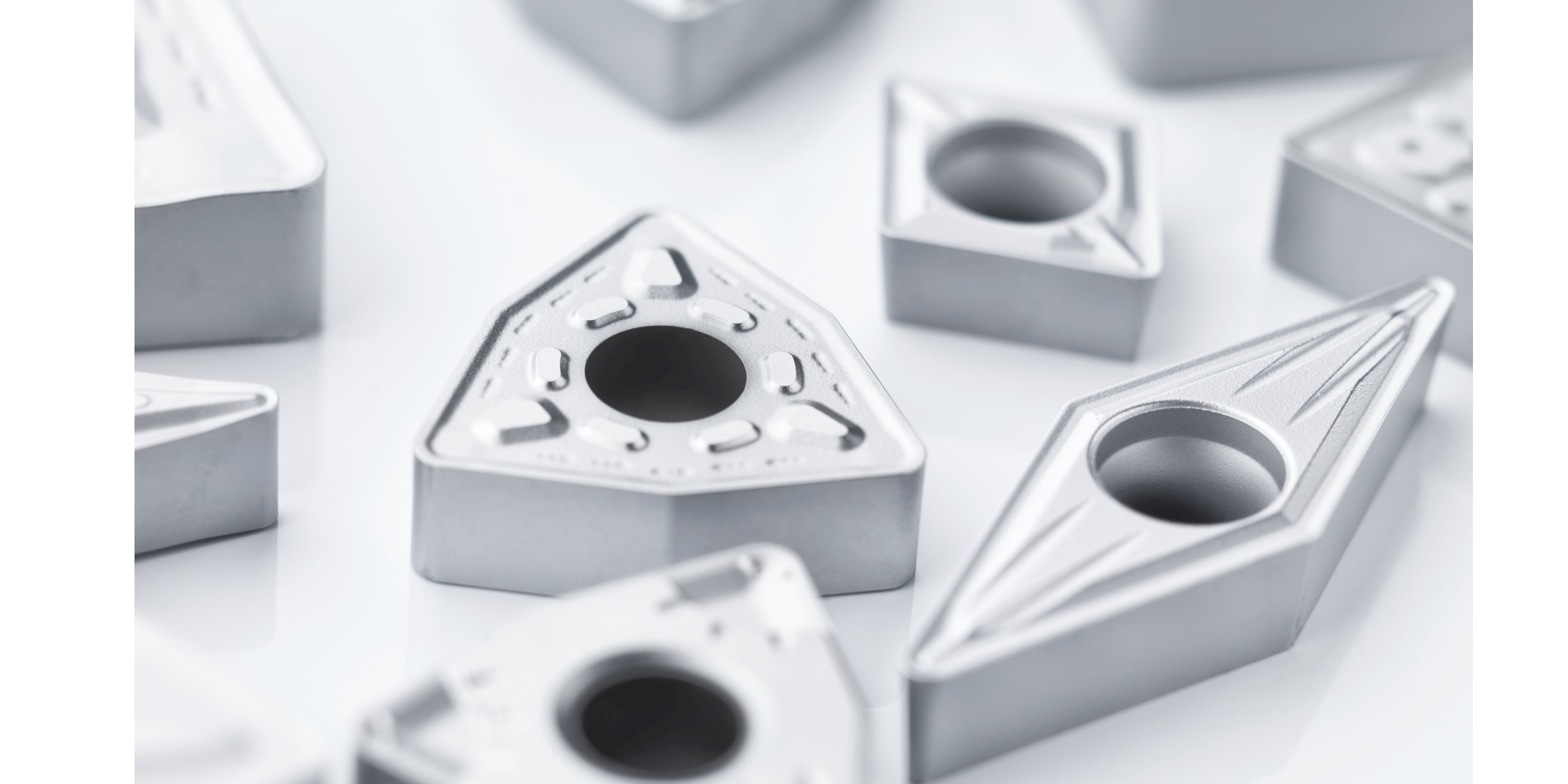

Inserttypes

Top management has a strong dedication to cutting-edge technology. To provide the absolute best product and experience for our customer, each department is equipped with the latest in software and machinery.

From processing to delivery, your orders are handled by professionals. By cultivating a family atmosphere, we have been able to maintain a low employee turnover. Each department operates with employees who have 20+ years of experience with our company.

Insertnose radius chart

We tool all makes and models of single- and multi-spindle screw machines, as well as rotary transfer and CNC machines. Every tooling package we manufacture is built with precision and is 100% performance guaranteed.

Carbideinsert identificationchart PDF

Established in Hendersonville, Tennessee in 1980, Crowley Tool Company has grown from a humble three-person family business to an internationally recognized leading provider of custom insert tooling solutions.

Crowley Tool Company specializes in designing and manufacturing precision insert form tools and tooling packages for the parts-making industry. We are ISO 9001:2015 certified and maintain a robust international presence.

Millinginsertspecification

The ISO designation system for toolholders for turning applicationsFor turning toolholders, as for indexable inserts, there is a similar ISO designation system.The system is designed so that each important feature and dimension of the toolholder is shown using a code system. This becomes the name of the toolholder. This system has several advantages:Unique naming of a toolholder (supplier independent)All important features and dimensions are clearly stated in the nameSome code positions relate to the insert that can be used in the toolholder It's important to remember that the ISO designation system is not a system that standardizes the quality of the toolholders. Here is an example for external turning toolholders (metric) ISO standards Turning Here is an example for internal turning toolholders (metric) Do you want to know more?Contact Us Inline Content - SurveyCurrent code - 5fce8e61489f3034e74adc64

It's important to remember that the ISO designation system is not a system that standardizes the quality of the toolholders.

ISOturning insertnomenclature

The Crowley team prides itself on delivering the highest standard of customer service. Our continued success is built on long-lasting relationships with each of our customers. When you choose Crowley Tool as your supplier, you become a part of a winning team.

Our engineering team uses the latest AutoCAD 2D and 3D design software to engineer your custom tooling solution from the ground up. At Crowley Tool, we approach each project as a blank slate with unique problems to solve and challenges to overcome. We work closely with our customers to ensure that we design, build and deliver the most precise and efficient tooling solution for every job.

Our company is ISO 9001:2015 certified. Our commitment to quality control, lean manufacturing and continuous improvement is unwavering. Proprietary tracking software, built specifically for our processes, allows each tool to be monitored from start to finish.

The system is designed so that each important feature and dimension of the toolholder is shown using a code system. This becomes the name of the toolholder.

0086-813-8127573

0086-813-8127573