Thread Mills — Scientific Cutting Tools, Inc. - single point thread mill

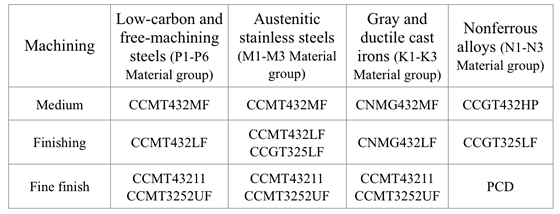

Due to the magazine’s space limitations, the authors provide the following tables showing most popular Kennametal’s indexable inserts only for general turning of steel, cast iron, and nonferrous alloys. These tables don’t cover all Kennametal chip breakers. (Figure 4 and Figure 5 also show Kennametal Inc. insert identification system and chip breaker identification system respectively.)

CARBIDE REAMERS: Made from premium Micro-Grain Carbide, they are precision ground to tight tolerances, provide superior finishes, improved hole sizes, and can be ran at higher speeds and feeds.

Inserts selection depends on workpiece material, chip control, surface finish, tool life, and the machine tool’s power and torque requirements. One of the commonly used indexable inserts for general turning is CNMG 432.

A reamer is a type of rotary cutting tool used in metalworking. Precision reamers are designed to enlarge the size of a previously formed hole by a small amount but with a high degree of accuracy to leave smooth sides. ... The process of enlarging the hole is called reaming. Reamer - Wikipedia

...Supplying High Quality Tools and Supplies for Machine Shops, Plant Engineering and Maintenance Since 1955 ... We ship worldwide.

Replaceable tool that clamps into a tool body, drill, mill or other cutter body designed to accommodate inserts. Most inserts are made of cemented carbide. Often they are coated with a hard material. Other insert materials are ceramic, cermet, polycrystalline cubic boron nitride and polycrystalline diamond. The insert is used until dull, then indexed, or turned, to expose a fresh cutting edge. When the entire insert is dull, it is usually discarded. Some inserts can be resharpened.

ID grooveinsert

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

American National Standard ANSI B212.4-2002 covers the identification system for indexable-type inserts for both single-point and multiple-point cutting tools. It was published on October 29, 2002. The earlier editions of the standard are:

The descriptions, illustrations, specifications, dimensions, and part numbers are subject to change without notice.

Adjustable Hand Reamers are versatile tools each capable of reaming a series of odd sized holes over a limited range of adjustment

DOWEL PIN REAMERS: Made with a minus tolerance, used for reaming holes for dowel pins in the automotive industry and mold shops.

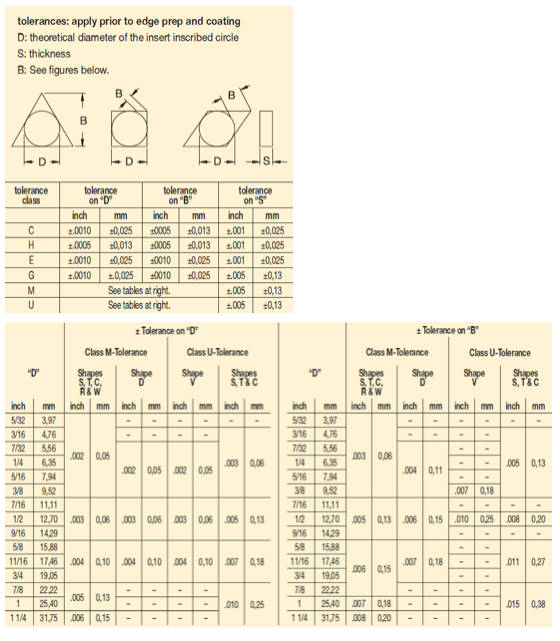

Tolerances on dimensions (± from nominal) are denoted by letters A, B and T. Dimension A is the nominal inscribed circle (I.C.) of the insert. Dimension T is the thickness of the insert. For pentagon, triangle and trigon shapes, dimension B is the insert height, i.e., the distance between one side and the opposite corner (Figure 2).

Roundinsert turningtool

For all other polygons, dimension B is the distance, measured along the bisector of the rounded off corner angle and a gage roll of nominal I.C. size tangent to the two sides opposite the corner (Figure 2). For example, if a tolerance letter is H, tolerances on dimensions (± from nominal) are: 0.0005" on dimension A, 0.0005" on dimension B and 0.001" on dimension T.

The 10th position is only used if there are letters in the seventh position. It will be a significant number representing the nominal sixty-fourths of an inch in length of the primary facet: 1 – 1 ⁄ 64"; 2 – 1 ⁄ 32"; 3 – 3 ⁄ 64"; 4 – 1 ⁄ 16"; 5 – 5 ⁄ 64"; 6 – 3 ⁄ 32"; 7 – 7 ⁄ 64"; 8 – 1 ⁄ 8"; 9 – 9 ⁄ 64"; 10 – 5 ⁄ 32".

Edmund Isakov, Ph.D., is a consultant, writer and frequent CTE contributor. He is the author of the books “Mechanical Properties of Work Materials” (Modern Machine Shop Publications, 2000); “Engineering Formulas for Metalcutting” (Industrial Press, 2004); “Cutting Data for Turning of Steel” (Industrial Press, 2009); the CD-ROM “International System of Units (SI)” (Industrial Press, 2012); and the software “Advanced Metalcutting Calculators” (Industrial Press, 2005). For more information, call (561) 369-4063 or visit www.edmundisakovphd.com.

About the Authors: Edmund Isakov, Ph.D., is a consultant, writer, and frequent CTE contributor. He is the author of four books “Mechanical Properties of Work Materials” (Modern Machine Shop Publications, 2000); “Engineering Formulas for Metalcutting” (Industrial Press, 2004); “Cutting Data for Turning of Steel” (Industrial Press, 2009); “International System of Units (SI)” the CD-ROM (Industrial Press, 2013); and the software “Advanced Metalcutting Calculators” (Industrial Press, 2005). For more information, call (561) 369-4063, or email: edmundisakov9701@comcast.net. Shi ‘Steve’ Chen is Manager Product Engineering Turning at Kennametal Inc. For more information, call (724) 539-5321, or email: Shi.Chen@Kennametal.com

The seventh position indicates the cutting point configuration: a radius or a facet. In the case of a radius, the number indicates how many of 1 ⁄ 64 of an inch in the radius: 0 – sharp corner (0.002" max. radius); 0.2 – 0.004"; 0.5 – 0.008"; 1 – 1 ⁄ 64"; 2 – 1 ⁄ 32"; 3 – 3 ⁄ 64"; 4 – 1 ⁄ 16"; 5 – 5 ⁄ 64"; 6 – 3 ⁄ 32"; 7 – 7 ⁄ 64"; 8 – 1 ⁄ 8"; 10 – 5 ⁄ 32"; 12 – 3 ⁄ 16" 14 – 7 ⁄ 32" = 14; 16 – 1 ⁄ 4"; X – Any other corner radius.

COBALT REAMERS: Made in a variety of sizes and styles, Cobalt Reamers afford quality finishes and increased tool life.

Imaginary circle that touches all sides of an insert. Used to establish size. Measurements are in fractions of an inch and describe the diameter of the circle.

It is a two-digit number carried to one decimal place when it is not a whole number: 1.2 – 5 ⁄ 64"; 1.5 – 3 ⁄ 32"; 2.5 – 5 ⁄ 32"; 3.5 – 7 ⁄ 32".

Nine relief angle values have been described in ANSI B212.12-1991 standard. These angles are the difference from 90° measured in a plane normal to the cutting edge generated by the angle between the flank and top surface of the insert. Each relief angle is denoted by a capital letter as follows:

The fifth position is a significant one- or two-digit number indicating the size of the inscribed circle (I.C.) for all inserts having a true I.C. such as Round, Square, Triangle, Trigon, Pentagon, Hexagon, Octagon, and Diamond. This position designates the number of eighths of an inch in the nominal size of the I.C. It will be a one-digit number when the number of eighths of an inch in the I.C. is a whole number: 1 – 1 ⁄ 8"; 2 – 1 ⁄ 4"; 3 – 3 ⁄ 8"; 4 – 1 ⁄ 2"; 5 – 5 ⁄ 8"; 6 – 3 ⁄ 4"; 7 – 7 ⁄ 8";

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

CAR REAMERS: Car Reamers are designed for Railroad Car building work. A special cutting chamfer allows for easy entry and fast cutting in badly offset and burnt holes.

Tungaloyinsertgrades

There are 16 standard shapes of indexable inserts, and each shape is identified by a capital letter as follows (Figure 1):

1. Shape (e.g., A, C, D): 2. Clearance (e.g., A, B, C): 3. Tolerance Class (e.g., A, B, C): 4. Type (e.g., A, B, C): 5. Size Code: 6. Thickness Code: 7. Cutting-Point Configuration (e.g., 0, 0.5, A): 8. Edge Preparation (e.g., A, B, C): 9. Hand (R, L, N): 10. Facet Size: Decode Insert

The sixth position is a significant one- or two-digit number indicating the number of sixteenths of an inch in the thickness of the insert. It is a one-digit number when the number of sixteenths of an inch in the thickness is a whole number: 1 – 1 ⁄ 16"; 2 – 1 ⁄ 8"; 3 – 3 ⁄ 16"; 4 – 1 ⁄ 4"; 5 – 5 ⁄ 16"; 6 – 3 ⁄ 8"; 7 – 7 ⁄ 16"; 8 – 1 ⁄ 2"; 9 – 9 ⁄ 16"; 10 – 5 ⁄ 8".

Turninginserts

ANSI B212.4-2002 standard added one more capital letter O, which denotes other relief angles for new designs of indexable inserts.

According to ANSI B212.4-2002 standard, identification of the indexable insert includes 10 positions denoted by a capital letter. Each position (from 1 to 10) defines a characteristic of the insert in the following order:

BRIDGE REAMERS: Bridge Reamers are designed for use in structural steel, in the building industry, bridge erection, and ship construction. The cutting end of the flutes is tapered therefore allowing the reamer not only to enter overlapping holes but also permits insertion into very badly misaligned holes. Bridge Reamers are commonly used in portable electric or pneumatic machines.

Space provided behind the cutting edges to prevent rubbing. Sometimes called primary relief. Secondary relief provides additional space behind primary relief. Relief on end teeth is axial relief; relief on side teeth is peripheral relief.

There are 14 tolerance classes that control the indexability of the inserts. Each class is denoted by a capital letter. Letters for tolerances are A, B, C, D, E, F, G, H, J, K, L, M, U and N.

In case of a facet, two letters are used. The first letter designates the facet angle: A – 45°; D – 60°; E – 75°; G – 87°; P – 90°; Z – Any other facet angle. The second letter designates the facet clearance angle:

Cermet inserts

servicing the Canadian provinces and territories of Newfoundland, NF, NL, Nova Scotia, NS, New Brunswick, NB, Prince Edward Island, PEI, PE, Quebec, PQ, QC, Ontario, ON, Manitoba, MB, Saskatchewan, SK, Alberta, AB, British Columbia, BC, Northwest Territories, NT, Nunavut, NU, Yukon, YT, servicing Canadian cities, Toronto, Mississauga, Scarborough, Laval , Montreal, Montréal, Vancouver, Ottawa, Gatineau, Calgary, Edmonton, Québec City, Winnipeg, Hamilton, Kitchener, Cambridge, Waterloo, London, St. Catharines , Niagara, Halifax, Oshawa, Victoria, Windsor, Saskatoon, Regina, Sherbrooke, St. John's, Barrie, Kelowna, Abbotsford, Mission, Sudbury Kingston, Saguenay, Trois-Rivieres, Trois Rivieres, Trois-Rivières, Guelph, Moncton, Brantford, Saint John, Thunder Bay, Peterborough, Ajax, Aurora, Brampton, Brock, Burlington, Caledon, Clarington, Durham Region, Oshawa, Pickering, Whitby, Halton Hills, Milton, Oakville, Mississauga, New market, Richmond Hill, Vaughn, Orangeville, servicing US cities, New York, Los Angeles, Chicago, Houston, Philadelphia, Phoenix, San Antonio, San Diego, Dallas, San Jose, Austin, Jacksonville, San Francisco, Indianapolis, Columbus, Fort Worth, Charlotte, Seattle, Denver, El Paso, Detroit, Washington, Boston, Memphis, Nashville, Portland, Oklahoma City, Las Vegas, Baltimore, Louisville, Milwaukee, Albuquerque, Tucson, Fresno, Sacramento, Kansas City, Long Beach, Mesa, Raleigh, Omaha, Miami, Oakland, Minneapolis, Tulsa, Wichita, New Orleans, Arlington, Cleveland, Bakersfield, Tampa, Aurora, Honolulu, Anaheim, Santa Ana, Corpus Christi, Riverside, St. Louis, Lexington, Stockton, Pittsburgh, Saint Paul, Anchorage, Cincinnati, Henderson, Greensboro, Plano, Newark, Toledo, Lincoln, Orlando, Chula Vista, Jersey City, Chandler, Fort Wayne, Buffalo, Durham, St. Petersburg, Irvine, Laredo, Lubbock, Madison, Gilbert, Norfolk, Reno, Winston Salem, Glendale, Hialeah, Garland, Scottsdale, Chesapeake, North Las Vegas, Fremont, Baton Rouge, Richmond, Boise, San Bernardino, Spokane, Birmingham, Modesto, Des Moines, Rochester, Tacoma, Fontana, Oxnard, Moreno Valley, Fayetteville, Huntington Beach, Yonkers, Glendale, Aurora, Montgomery, Columbus, Amarillo, Little Rock, Akron, Shreveport, Augusta, Grand Rapids, Mobile, Salt Lake City, Huntsville, Tallahassee, Grand Prairie, Overland Park, Knoxville, Worcester, Brownsville, Newport News, Santa Clarita, Port St. Lucie, Providence, Fort Lauderdale, Chattanooga, Tempe, Oceanside, Garden Grove, Rancho Cucamonga, Cape Coral, Santa Rosa, Vancouver, Sioux Falls, Peoria, Ontario, Jackson, Elk Grove, Springfield, Pembroke Pines, Salem, Corona, Eugene, McKinney, Fort Collins, Lancaster, Cary, Palmdale, Hayward, Salinas, Frisco, Springfield, Pasadena, Macon, Alexandria, Pomona, Lakewood, Sunnyvale, Escondido, Kansas City, Hollywood, Clarksville, Torrance, Rockford, Joliet, Paterson, Bridgeport, Naperville, Savannah, Mesquite, Syracuse, Pasadena, Orange, Fullerton, Killeen, Dayton, McAllen, Bellevue, Miramar, Hampton, West Valley City, Warren, Olathe, Columbia, Thornton, Carrollton, Midland, Charleston, Waco and the states of Alabama, AL, Alaska, AK, Arizona, AZ, Arkansas, AR, California, CA, Colorado, CO, Connecticut, CT, Delaware, DE, District of Columbia, DC, Florida, FL, Georgia, GA, Hawaii, HI, Idaho, ID, Illinois, IL, Indiana, IN, Iowa, IA, Kansas, KS, Kentucky, KY, Louisiana, LA, Maine, ME, Maryland, MD, Massachusetts, MA, Michigan, MI, Minnesota, MN, Mississippi, MS, Missouri, MO, Montana, MT, Nebraska, NE, Nevada, NV, New Hampshire, NH, New Jersey, NJ, New Mexico, NM, New York, NY, North Carolina, NC, North Dakota, ND, Ohio, OH, Oklahoma, OK, Oregon, OR, Pennsylvania, PA, Rhode Island, RI, South Carolina, SC, South Dakota, SD, Tennessee, TN, Texas, TX, Utah, UT, Vermont, VT, Virginia, VA, Washington, WA, West Virginia, WV, Wisconsin, WI, Wyoming, WY We can ship to Afghanistan , Aland Islands , Albania , Algeria , American Samoa , AS, Andorra , Angola , Anguilla , Antigua & Barbuda , Argentina , Armenia , Aruba , Australia , Austria , Azerbaijan , Azores , Bahamas , Bahrain , Bangladesh , Barbados , Belarus , Belgium , Belize , Benin , Bermuda , Bhutan , Bolivia , Bonaire , Bosnia , Botswana , Brazil , British Virgin Isles , Brunei , Bulgaria , Burkina Faso , Burundi , Cambodia , Cameroon , Canada , Canary Islands , Cape Verde , Cayman Islands , Central African Republic , Chad , Chile , China , Colombia , Comoros , Congo , Cook Islands , Costa Rica , Croatia , Curacao , Cyprus , Czech Republic , Democratic Republic of Congo , Denmark , Djibouti , Dominica , Dominican Republic , Ecuador , Egypt , El Salvador , England , Equatorial Guinea , Eritrea , Estonia , Ethiopia , Faeroe Islands , Fiji , Finland , France , French Guiana , French Polynesia , Gabon , Gambia , Georgia , Germany , Ghana , Gibraltar , Greece , Greenland , Grenada , Guadeloupe , Guam , GU, Guatemala , Guernsey , Guinea , Guinea-Bissau , Guyana , Haiti , Holland , Honduras , Hong Kong , Hungary , Iceland , India , Indonesia , Iraq , Ireland , Israel , Italy , Ivory Coast , Jamaica , Japan , Jersey , Jordan , Kazakhstan , Kenya , Kiribati , Kosrae , Kuwait , Kyrgyzstan , Laos , Latvia , Lebanon , Lesotho , Liberia , Libya , Liechtenstein , Lithuania , Luxembourg , Macau , Macedonia (Fyrom) , Madagascar , Madeira , Malawi , Malaysia , Maldives , Mali , Malta , Marshall Islands , MH, Martinique , Mauritania , Mauritius , Mayotte , Mexico , Micronesia , Moldova , Monaco , Mongolia , Montenegro , Montserrat , Morocco , Mozambique , N. Mariana Islands , Namibia , Nepal , Netherlands , Netherlands Antilles , New Caledonia , New Zealand , Nicaragua , Niger , Nigeria , Norfolk Island , Northern Ireland , Norway , Oman , Pakistan , Palau , PW, Panama , Papua New Guinea , Paraguay , Peru , Philippines , Poland , Ponape , Portugal , Puerto Rico , PR, Qatar , Reunion , Romania , Rota , Russia , Rwanda , Saba , Saipan , San Marino , Saudi Arabia , Scotland , Senegal , Serbia , Seychelles , Sierra Leone , Singapore , Slovakia , Slovenia , Solomon Islands , South Africa , South Korea , Spain , Sri Lanka , St. Barthelemy , St. Christopher , St. Croix , St. Eustatius , St. John , St. Kitts & Nevis , St. Lucia , St. Maarten , St. Martin , St. Thomas , St. Vincent/Grenadines , Suriname , Swaziland , Sweden , Switzerland , Syria , Tahiti , Taiwan , Tajikistan , Tanzania , Thailand , Timor Leste , Tinian , Togo , Tonga , Tortola , Trinidad & Tobago , Truk , Tunisia , Turkey , Turkmenistan , Turks & Caicos Islands , Tuvalu , Uganda , Ukraine , Union Island , United Arab Emirates , United Kingdom , United States , Uruguay, US Virgin Islands , VI, Uzbekistan , Vanatu , Vatican City State , Venezuela , Vietnam , Virgin Gorda , Wales , Wallia & Futuna Islands , Western Samoa , Yap , Yemen , Zambia , Zimbabwe we try to ship to the world largest cities Tokyo,Japan, Seoul, South Korea, Mexico City, Mexico , New York City, USA , Mumbai, India , Jakarta, Indonesia , Sáo Paulo, Brazil, Delhi, India , Osaka/Kobe, Japan , Shanghai, China , Manila, Philippines ,Los Angeles, USA ,Calcutta, India , Moscow, Russian Fed., Cairo, Egypt, Lagos, Nigeria, Buenos Aires, Argentina , London, United Kingdom , Beijing, China , Karachi, Pakistan , Dhaka, Bangladesh , Rio de Janeiro, Brazil ,Tianjin, China , Paris, France , Istanbul, Turkey , Lima, Peru , Tehrãn, Iran, Bangkok, Thailand , Chicago, USA , Bogotá, Colombia , Hyderabad, India , Chennai, India , Essen, Germany , Ho Chi Minh City, Vietnam , Hangzhou, China , Hong Kong, China , Lahore, Pakistan , Shenyang, China , Changchun, China , Bangalore, India , Harbin, China , Chengdu, China , Santiago, Chile ,Guangzhou, China , St. Petersburg, Russian Fed , Kinshasa, DRC , Baghdãd, Iraq , Jinan, China , Houston, USA , Toronto, Canada, Yangon, Myanmar (Burma), Alger, Algeria Philadelphia, USA, Qingdao, China , Milano, Italy , Pusan, South Korea, Belo Horizonte, Brazil, Almadabad, India , Madrid, Spain , San Francisco, USA, Alexandria, Egypt , Washington DC, USA , Wuhan, China , Dallas, USA , Guadalajara, Mexico, Chongging, China , Medellin, Colombia, Detroit, USA , Handan, China , Frankfurt, Germany , Porto Alegre, Brazil , Hanoi, Vietnam , Sydney, Australia, Santo Domingo, Dom. Rep., Singapore, Singapore , Casablanca, Morocco , Katowice, Poland , Pune, India , Bangdung, Indonesia, Monterrey, Mexico ,Montréal, Canada , Nagoya, Japan , Nanjing, China , Abidjan, Côte d'Ivoire, Xi'an, China , Berlin, Germany , Riyadh, Saudi Arabia, Recife, Brazil , Dusseldorf, Germany, Ankara, Turkey , Melbourne, Australia, Salvador, Brazil , Dalian, China , Caracas, Venezuela, Adis Abeba, Ethiopia, Athina, Greece, Cape Town, South Africa, Koln, Germany , Maputo, Mozambique, Napoli, Italy

TAPER PIPE REAMERS: Taper Pipe Reamers are used before tapping with a variety of different types of pipe taps those include NPTF, Dryseal, and ANPT.

CBNTurninginserts

HAND REAMERS: Designed to be used by hand these reamers have a tapered lead for easy entry and a square on the end for use by a wrench. Used by maintenance and many other applications where the holes need to be reamed by hand.

Tool that cuts a sloped depression at the top of a hole to permit a screw head or other object to rest flush with the surface of the workpiece.

| Adjustable Expanding | Automotive Taper | Bridge | Brown & Sharpe Taper | Car | Carbide | Chucking | Cobalt | Decimal | Die Makers | Dowel Pin | Expanding Adjustable | Hand Reamers | Jarno Taper | Morse Taper | P62 | RWMA Welding Equipment | Shell | | Stub Screw Machine | Taper Pin | Taper Pipe | Taper Shank | Tapered |

TurningTool Holder

Conditioning of the cutting edge, such as a honing or chamfering, to make it stronger and less susceptible to chipping. A chamfer is a bevel on the tool’s cutting edge; the angle is measured from the cutting face downward and generally varies from 25° to 45°. Honing is the process of rounding or blunting the cutting edge with abrasives, either manually or mechanically.

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

The fourth position is a capital letter denoting differences in design of insert, such as the existence of fixing holes, countersinks and special features on rake surfaces. There are 15 standard types in design as follows (Figure 3):

Order on Line CHUCKING REAMERS: A general purpose Reamer that is used in a variety of applications and materials. These are available in a variety of different styles such as Straight Shank, Taper Shank, and Stub Screw Machine.

Tungaloy inserts catalog

Explanation: Enter each code position to decode the specific insert characteristics according to ANSI B212.4-2002 standards.

1. Shape2. Clearance3. Tolerance class4. Type5. Size6. Thickness7. Cutting-point configuration8. Edge preparation9. Hand10. Facet size

TAPER SHANK: Designed to fit MORSE Taper Sockets and Sleeves. These Reamers are similar in design to Straight Shank Reamers. They can be used in a number of different types of applications and materials.

It will be a two-digit number carried to one decimal place when it is not a whole number: 1.2 – 5 ⁄ 32"; 1.5 – 3 ⁄ 16"; 1.8 – 7 ⁄ 32"; 2.5 – 5 ⁄ 16".

On rectangular and parallelogram inserts, the width and length dimensions are used in place of the I.C. A two-digit number designates the sizes of these inserts. The first digit indicates the number of eighths of an inch in the width and the second digit indicates the number of fourths of an inch in the length of the insert.

TAPER PIN REAMERS: These are designed for reaming holes so that standard taper pins will be able to fit properly. Best results will be attained if the hole is drilled a few thousandths smaller than the small diameter of the finished reamed hole.

Adjustable Hand Reamers are versatile tools each capable of reaming a series of odd sized holes over a limited range of adjustment

The mathematical expression denoting one of several parameters that describe surface texture (same as average roughness Ra). Average roughness is the arithmetic average height deviation of the measured surface profile from the profile centerline. See surface texture.

0086-813-8127573

0086-813-8127573