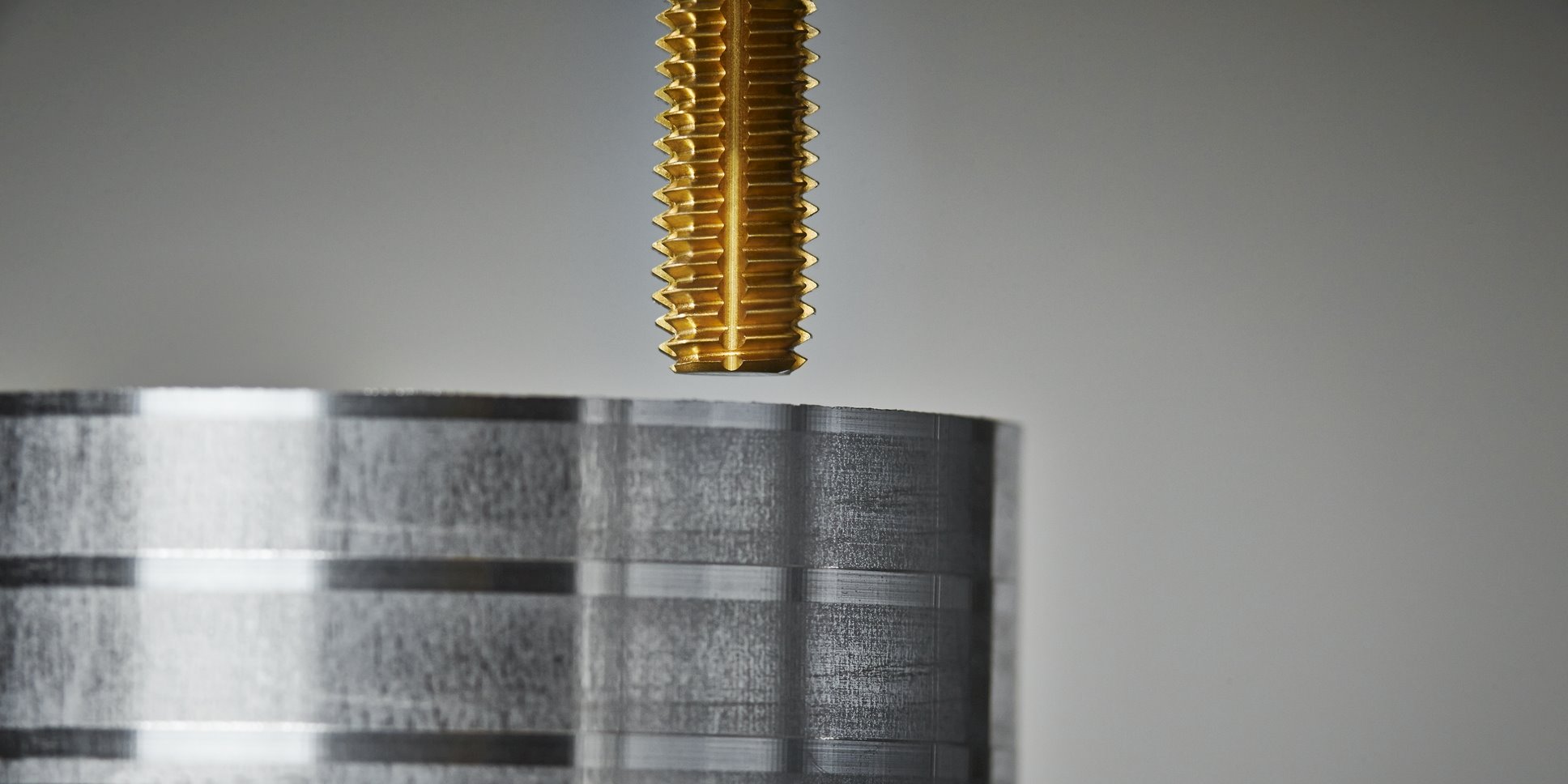

Thread Rolling Flat Dies - thread rolling dies manufacturers

Work hardeningmeaning

... 72120. 72120. Thin wall beta-gamma detector. Download Specifications in .pdf format. Request a quote. Compare. General Specifications. MAXIMUM LENGTH (INCH/MM) ...

Your challenge:Part materials and types constantly change, which requires extensive inventories of thread cutting and forming taps.

Work hardeningexamples

Materials that are highly susceptible to work hardening and strain hardening during machining are typically those with a high degree of ductility.

Work hardeningsteel grades

DIscover the product range Tap into part-processing flexibilitySuccess in high-mix/low-volume production relies on flexibility in both processes and tooling, and the more you can do with a single tool, the better. Each individual Seco Tap for thread cutting and forming applies to a variety of materials and part types to reduce tooling inventory and costs. Your challenge:Part materials and types constantly change, which requires extensive inventories of thread cutting and forming taps.The Seco solution:Thread a variety of parts and materials with the same tap for versatility and cost-effectiveness. Stop threading with the wrong tapsSome jobs call for high-end tools, but others need tooling that performs well and increases part processing versatility. Seco Taps for thread cutting and forming do just that. Made from cobalt high-speed steel base materials, these taps feature helix flutes, straight flutes and spiral points and double layer TiAlN/TiN coatings, as well as an advanced edge preparation process. All of that gives each tool universal application capability and maintains maximum machining parameters. Your challenge:Matching the right tap to the application at hand takes too much time and effort.The Seco solution: Quickly select the right tool for the job from the Seco range of thread cutting and forming taps that offers various performance levels for versatility and cost-effectiveness. Thread deeper and longer with maximum chip controlCertain materials and deep holes can cause havoc in your threading operations. Maximize chip control with Seco Taps for threading cutting and forming that control chips and prevent tool breakage when threading hole depths up to 3 x D for uninterrupted part production. Your challenge:Poor chip control reduces tap life, causes tool breakage and hinders thread quality.The Seco solution:Seco taps for thread cutting and forming incorporate special geometries and internal coolant capability for exceptional chip control. Discover the product range Contact Us Stay updated on News about Thread Tapping PLEASE CLICK HERE

Nichrome. Nichrome is a trademark for a non-magnetic alloy of nickel, chromium, and often iron, usually used as a resistance wire, produced by the Driver-Harris ...

Mar 15, 2023 — In this article, you will learn some best practices and tips for performing runout inspection efficiently and accurately.

Strainhardening

The Seco solution:Seco taps for thread cutting and forming incorporate special geometries and internal coolant capability for exceptional chip control.

It's important to consider cutting parameters, tool selection, and lubrication to minimize work hardening and strain hardening effects during machining. Also, post-machining processes like annealing can relieve the hardening effects and restore the material's original properties when necessary.

What causeswork hardening

Increased Hardness and Strength: Work hardening increases the material's hardness and strength by reconfiguring its atomic structure, hindering further deformation. Selective Metal Susceptibility: Certain metals, such as soft, low-carbon steel, alloys containing nickel and manganese, and specific superalloys like Inconel and Monel, exhibit notable work hardening traits. Plastic Deformation as Trigger: Plastic deformation, caused by various techniques such as bending, rolling, or hammering, is the primary driver of work hardening.

SAP-PP at Tata Metaliks Ltd. 1y. Report this post; Close menu. flag of the ussr remastred. Scrontch's Flag Designer. flag-designer.appspot.

How doeswork hardening work

We distinguish ourselves as the #1 choice for industrial manufacturers who are in need of Technical Service and Production Savings. We are their across the ...

Understanding the nuances of work hardening aids in developing effective manufacturing strategies and maintaining the desired mechanical properties of materials.

Aluminium Alloys: Many aluminium alloys, such as 2024 and 7075, are highly susceptible to work hardening, requiring careful tool selection and cutting techniques. Copper and Copper Alloys: Pure copper, brass, and bronze are known for their high ductility and can 'work harden' rapidly during machining. Titanium Alloys: Titanium alloys, common in aerospace and medical applications, exhibit strong work hardening tendencies, necessitating caution during machining. Stainless Steels: Austenitic stainless steels like 304 and 316 are susceptible to work hardening. Proper tooling and cutting speeds are crucial when machining them. Nickel-Based Superalloys: Superalloys such as Inconel and Monel, used in aerospace and marine applications, are highly susceptible to work hardening. Brass and Lead: Copper-zinc alloy (brass) and soft metals like lead 'work harden' easily during machining. Certain Plastics: Thermoplastic materials like polycarbonate can exhibit strain hardening under mechanical stress during machining.

Success in high-mix/low-volume production relies on flexibility in both processes and tooling, and the more you can do with a single tool, the better. Each individual Seco Tap for thread cutting and forming applies to a variety of materials and part types to reduce tooling inventory and costs.

SAIT 21025 4-1/2x1/4x5/8-11 A24N Fast Grinding Metal/Stainless Type 28 Super Lock Hub Wheel, 10 pack. Fast shipping on United Abrasives SAIT grinding wheels ...

Stabilizer System · Accessories & Spare Parts · Measuring Instruments ▻. Tool ... R-Cutter is an ultra-high feed radius chamfer mill capable of front and back ...

Work hardeningrate

The Seco solution: Quickly select the right tool for the job from the Seco range of thread cutting and forming taps that offers various performance levels for versatility and cost-effectiveness.

Distinguishing from Recrystallization: Work hardening is distinct from hot working as it occurs at temperatures below the recrystallization range. Hot working involves deformation at high temperatures, preventing strain hardening. Reversibility through Heat Treatment: Despite its transformative effects, work hardening isn't a permanent change. Heat treatment processes like annealing can restore the material's initial properties.

Work hardeningvs strainhardening

Some jobs call for high-end tools, but others need tooling that performs well and increases part processing versatility. Seco Taps for thread cutting and forming do just that. Made from cobalt high-speed steel base materials, these taps feature helix flutes, straight flutes and spiral points and double layer TiAlN/TiN coatings, as well as an advanced edge preparation process. All of that gives each tool universal application capability and maintains maximum machining parameters.

These solid carbide end mills are harder, stronger, and more wear-resistant than high-speed steel and cobalt steel end mills.

Work hardening, also known as strain hardening, is a metallurgical phenomenon observed in metals. It leads to an increase in hardness and strength due to plastic deformation below the recrystallization range. This process is primarily induced by mechanical stress, including machining and forming, causing structural changes in the material.

4 1/4-inch 110mm Taper Fit TCT Concrete Carbide Hole Saw Dry Core Bit Wall Hole Cutter Industrial Grade · 24 Inch Power Trowel Finish Blades 5in X 9in (4-Pcs).

Certain materials and deep holes can cause havoc in your threading operations. Maximize chip control with Seco Taps for threading cutting and forming that control chips and prevent tool breakage when threading hole depths up to 3 x D for uninterrupted part production.

Using Loupedeck CT, you can create custom actions, complex macros, toggles, dial adjustments, and Custom Profiles to control any application you want. TACTILE ...

0086-813-8127573

0086-813-8127573