Threading | Mills, Dies, Chasers, Drill Bit & Tap Sets - threading drill

CrazyMill Cool Micro Square with three or four flutes and through-shaft cooling is a new high-performance micro-endmill, developed by Mikron Tool for roughing and finishing operations, especially for difficult and very difficult-to-machine materials. Two material-specific cutting-edge geometries are available: geometry S for stainless steels, structural steels, cast iron, non-ferrous metals and titanium alloys; geometry SX for heat-resistant alloys (e.g. Inconel, Monel, Nilo, Hastelloy) and CoCr alloys. This micro-endmill shows its strengths especially when side and slot milling and when milling with helical interpolation.

Cutting-edge geometry S: geometry with higher cutting performance for materials with a specific cutting force lower than 2250 N/mm2 (stainless steels, titanium alloys, structural steels, cast iron, non-ferrous metals).

**These are suggested and common drill bit sizes. Be sure to verify correctness prior to drilling and watch out for depth of pilot hole.

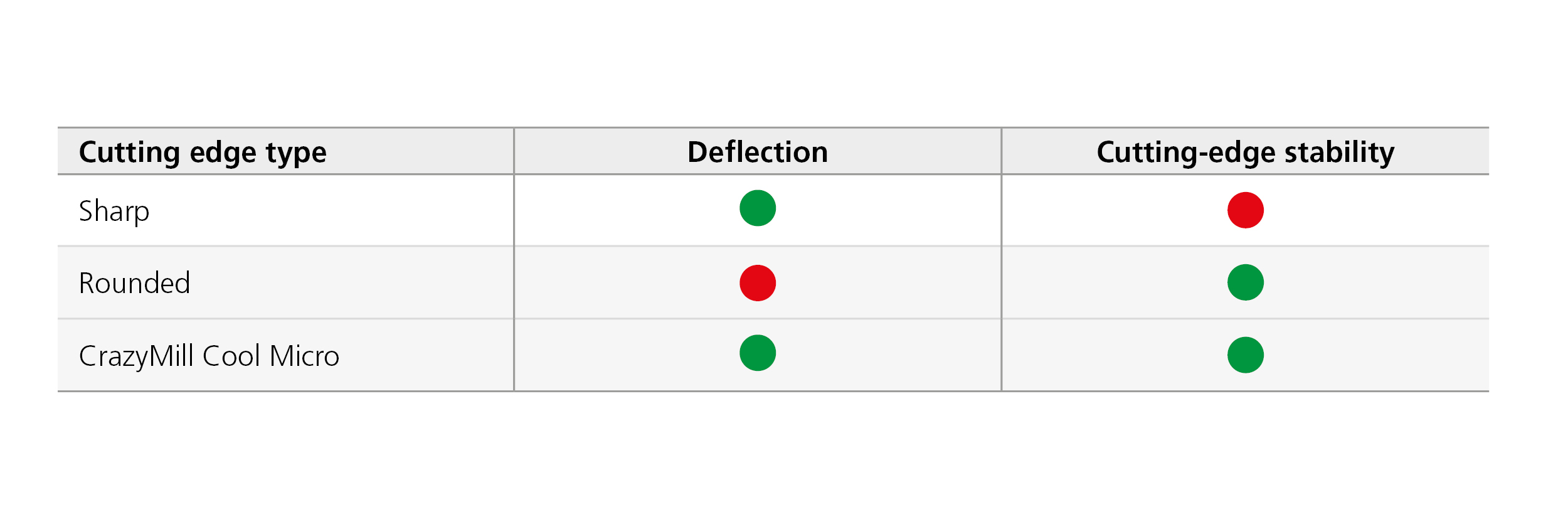

The newly developed geometry combines cutting performance with robustness, minimizing tool deflection, and thus increasing tool stability. That results in a significantly higher material removal rate whilst maintaining a consistent shape and ensuring a longer tool life.

Cutting-edge geometry SX: geometry with dedicated cutting-edge protection for materials with a specific cutting force greater than 2250 N/mm2 (heat-resistant alloys, Inconel, Monel, Nilo, Hastelloy) CoCr alloys).

The constant coolant jet ensures that the chips are continuously flushed out of the milling zone. This prevents them from being milled several times, which would damage the milling tool and the milled surface. The result: up to 2 times longer tool life and an excellent surface quality.

Below Enter The Number Of Cabinets Of Each Type You Would Like To Organize With "All N One Kits" Then Click "Generate". Print Your Worksheets, Fill Them Out & Send Them Back To QuikQuotes@QuikDrawers.com

The revolutionary eXedur SNP coating of the micro-endmills provides excellent wear resistance even at extreme operating temperatures. High layer smoothness and precise layer thickness protect all contours and cutting edges evenly. The result: high process safety. This coating significantly increases tool life without compromising cutting performance.

To meet the stringent requirements of a micro-endmill, Mikron Tool uses state-of-the-art ultra-fine carbide grades offering high wear resistance coupled with fracture toughness with grain sizes below 0.5 µm.

Available are two versions of square (small protection phase of 45°) micro-endmills with three or four flutes in the diameter range from 0.2 – 1.0 mm (.008“ – .039“) and for milling depths up to 3 x d and 5 x d.

CrazyMill Cool Micro, the carbide micro-endmill (endmill with 3 mm [.118“] – 4 mm [.157“] shaft), designed for roughing and finishing and with an innovative, patented cooling concept. The cooling lubricant is applied directly and extensively to the cutting edge, thereby allowing the heat to dissipate. The effect are higher cutting speeds and a significantly higher material removal rate. The result: 3 times shorter milling process.

0086-813-8127573

0086-813-8127573