Threading Specifications - minor thread diameter

Milling speeds and feedsChart

Milling calculator

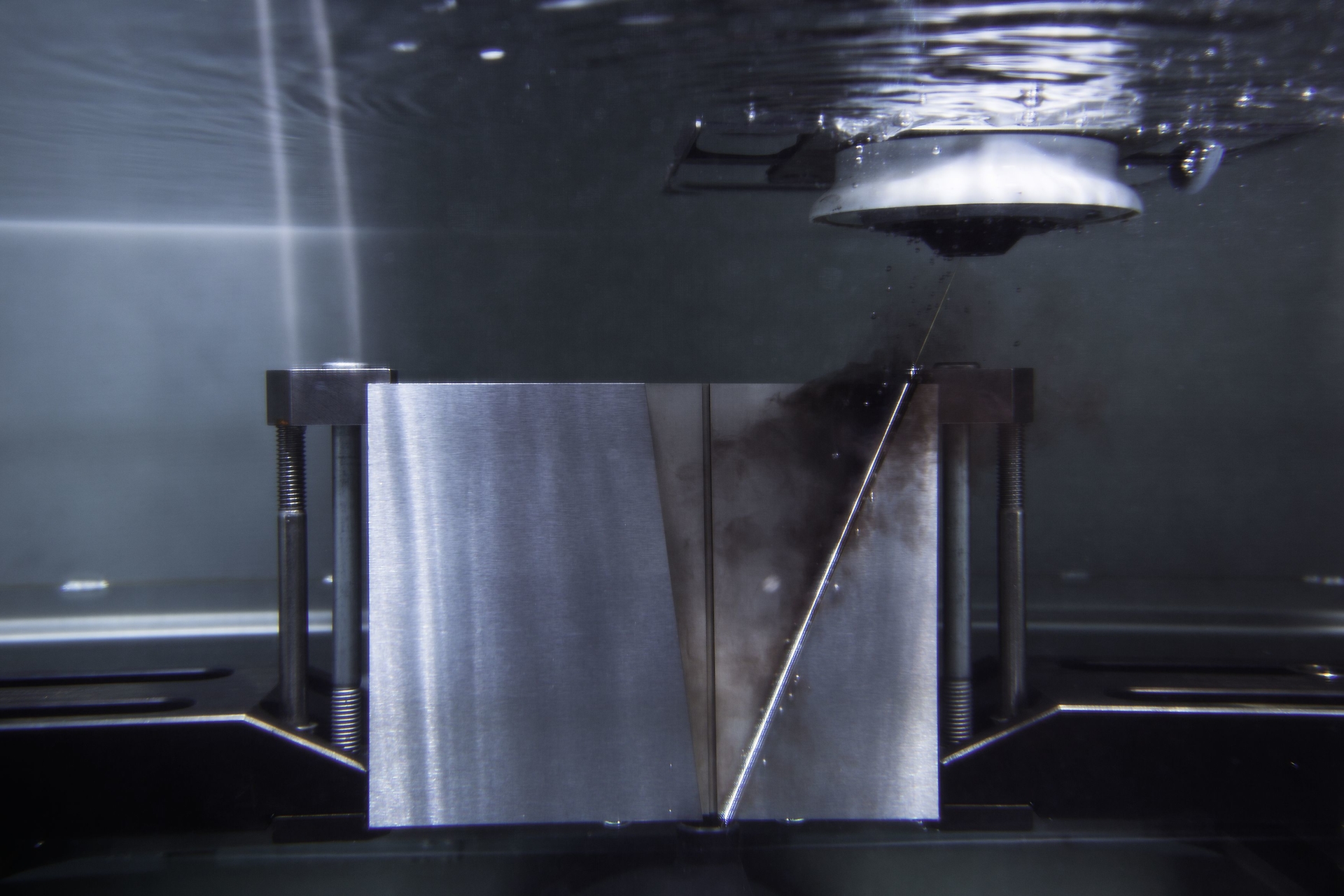

Simply drill holes in multiple configurations AgieCharmilles DRILL E 300 is a high-speed drill machine widely used for drilling starting holes. In aerospace for aircraft engines, as well as gas turbines in energy production, cooling holes are needed for creating a film of cooling air on the surface of turbine blades and vanes to prevent them from overheating. The DRILL E 300 is the perfect solution when you need to add small holes on a part with inclined faces or hard-to-reach positions.

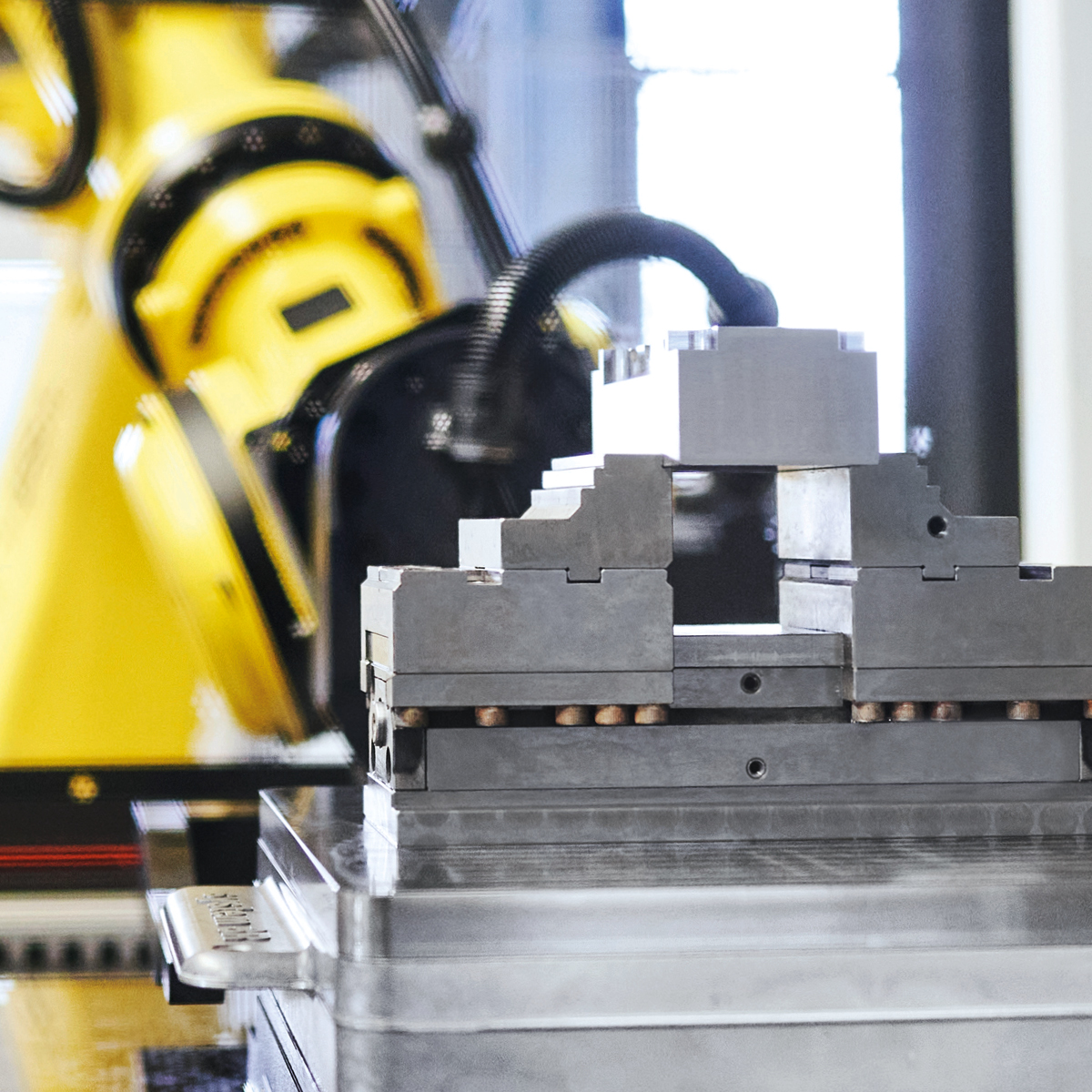

Process monitoring and optimization are implemented via the operator console. Sensors for short circuits, temperature and liquid level ensure safe operation. Numerical controlled X, Y and Z axes and a variety of touching cycles offer convenience to the operator when setting up.

MillingspeedandFeedcalculatormetric

Whatever the need, whether for small, large, through or blind holes, for single and multi-hole patterns, the adapted technology is automatically selected.

Turningspeeds and feeds calculator

Data input on the operator console is quick and simple. Technology settings are selected automatically by material electrode / piece, piece height and electrode diameter. Touching cycles can be programmed and called up with a few commands.

With drilling depths of up to 200 mm (7.78 in), DRILL E 300 is the ideal vertical drill for an extensive range of applications.

Its technology for fine electrodes Ø0.1 – 0.3 mm (0.004 – 0.012 in) make the DRILL E 300 suitable for drilling fine start holes on lead frames or high-speed stamping molds.

0086-813-8127573

0086-813-8127573