Threading-bits (set of 6 pcs.) M 3 – M 10 - Voelkel-Shop - threading bit

Cuttinghardened steelwith angle grinder

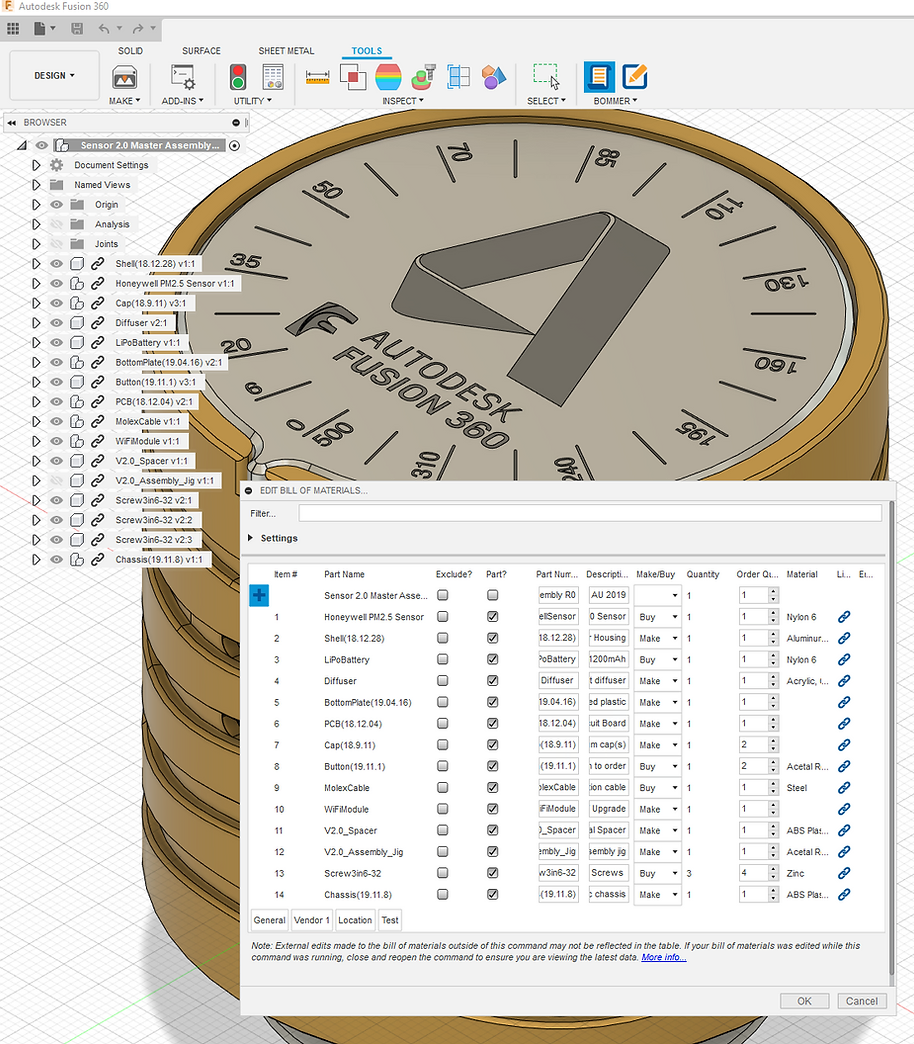

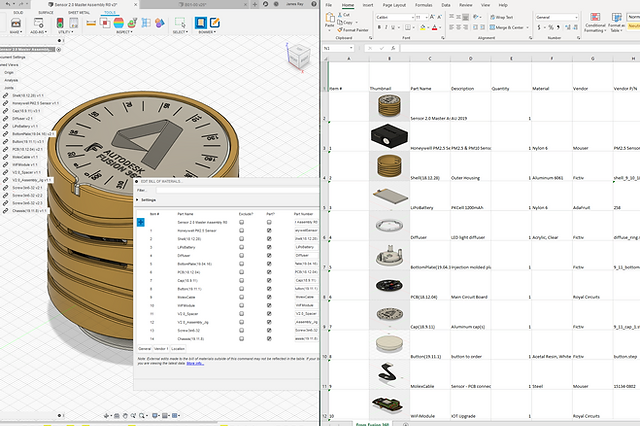

Bommer makes it easy to keep your data up to date and shared with your teams! All data is stored with your design files in the Autodesk cloud, so your teammates can see your work and collaborate.

Cuttinghardened steelwith Sawzall

Automatically capture and export component thumbnails, bounding box dimensions, mass properties, and other built-in design information. Build cut-lists and order lists with a few mouse clicks. Reclaim that time and focus more on your design!

Cuttinghardened steelwith Dremel

This article was co-authored by Himesh Patel and by wikiHow staff writer, Hunter Rising. Himesh Patel is a Metallurgical Engineer at Mcclelland Laboratories in Reno, Nevada. With over five years of industry and graduate research experience in the raw materials industry, Himesh has extensive knowledge of mining and mineral extraction and recovery methods, mine financing, and the environmental impacts of mining. He received his MS in Metallurgical Engineering from the University of Nevada, Reno, and a Dual Degree in Mineral Engineering from the Indian Institute of Technology (Indian School of Mines), Dhanbad. Himesh is passionate about educating the public about the minerals industry. There are 10 references cited in this article, which can be found at the bottom of the page. wikiHow marks an article as reader-approved once it receives enough positive feedback. This article received 28 testimonials and 90% of readers who voted found it helpful, earning it our reader-approved status. This article has been viewed 1,025,105 times.

Integrated directly into Fusion 360, Bommer is the only system that gives you real custom properties with your part data. Bommer lets users easily create custom properties that are specific to their exact needs.

Bommer lives within Autodesk® Fusion 360™ to let you build, capture, and export your project bill of materials, always on your own terms. Store your data alongside your designs in the Autodesk cloud and never misplace it again.

To harden steel, start by heating the metal directly with a blow torch until it turns a cherry red color. Then, use a pair of tongs to carry the steel to a container filled with water or vegetable, and submerge the hot metal in the liquid. When the liquid stops bubbling, remove the metal from the container and wipe off any excess liquid. To temper the steel so it isn't brittle, place it in an oven heated to 375 °F for 3 hours, and then it let it cool overnight. For more information on using a blowtorch and protecting the steel, scroll down! Did this summary help you?YesNo

Cuttinghardened steelon lathe

Cut hardened steelpadlock

Bring any of your Bommer properties to bear and build a table with any number of levels and rows. Easily make your parts lists work for your unique designs and drawings.

Cuttinghardened steelwith hacksaw

Easily access and edit all of your information in a single table or component by component. Even works for linked components! Search, filter, and organize your bill of materials to find your data fast.

If you need to use a blow torch, focus the flame tip on the area you want hardened. Keep heating the steel until you notice a blue color form on the metal. This signifies that the steel is tempered.

With full control over what properties you want to see in your BOM, editing in Excel is now a thing of the past. Your BOM data is now 3 clicks away from being ready to send off to the manufacturer!

Steel is a common durable alloy, and while most steel used in tools is already tough, you can harden it even more to prevent wear and tear. Hardened steel prevents knife blades from dulling and tools from bending and breaking. With a simple heating and quenching process, you can make your steel last for much longer!

0086-813-8127573

0086-813-8127573