Timken® SAF 22522 - 22522

A steel with a high hardenability is one which has a low critical cooling rate, so that even slow cooling will lead to a martensitic structure. This has the advantage that hard material can be generated without the risk of "quench cracking" due to high thermal gradients associated with rapid cooling. On the other hand, it means that hard (and brittle) material may inadvertently be produced in finished artefacts, notably as a result of welding operations.

Most heat treatments for steels begin by heating the specimen into the austenite phase field. The resulting austenite is then cooled continuously to room temperature. This is achieved by plunging the specimen into a bath of water or oil, or by removing it from the furnace to cool in air ("normalising"). If very slow cooling is required then the sample is left in the furnace which is switched off. The actual cooling rates may vary in different regions of the sample. These variations may be large since steels are relatively poor conductors of heat (thermal diffusivity of steel is about 10-5 m2 s-1, of copper about 10-4 m2 s-1).

2 days ago — Find the zip code for La Toscana in Mexico. La Toscana is located in Zacatecas, Mexico. The zip code for La Toscana is 98610. Places langitude ...

Standard Cut General-purpose design that offers good metal removal, and provides a smooth finish. Produces longer chips, and is excellent for cutting relatively hard materials that won’t clog the flutes.

The hardenability is not affected bysanfoundry

The hardenability may be represented by the critical cooling rate, or the critical distance along the bar at which the hardness (martensite content) starts to drop. It is useful to examine the microstructure and correlate it with the hardness as a function of position along the Jominy bar.

Which ofthefollowing factors increaseshardenabilityof a metal

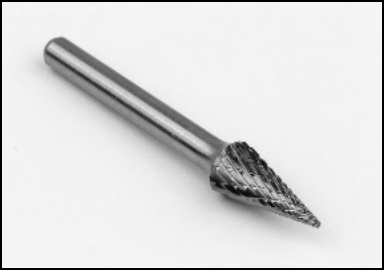

Good for deburring and finishing deep contoured surfaces in steel dies, molds, and metal patterns. Can also be used for repairing slug-damage spots on dies.

Indexable boring bars are single-point machine tools that use replaceable carbide inserts to size, straighten, and finish the inside of drilled or cast holes ...

(Fe-0.8 wt %C) steel. Curves are plotted for the onset and completion of reactions to form pearlite, bainite and martensite. The former two have the "C" shape because the driving force is small at high temperatures whereas diffusion becomes sluggish at low temperatures. Martensitic transformation is represented by a line parallel to the time axis, since no diffusion is involved and because of the very high rate of growth, the fraction transformed depends only on the temperature.

Good for deburring and finishing the curved top inside wall of steel dies, castings, forgings, or metal patterns. Can also be used to repair slug-damage spots on dies.

Hardenabilityof steelisa measure of

Carbide rotary burrs, also known as die grinder bits or rotary files, are used to cut, shape, chamfer, and grind a variety of metals and other hard materials, as well as for removing excess material, sharp edges, and burrs from parts. These burrs are solid carbide, with a bright, uncoated finish. They are available in three cut types, and a variety of common shapes suitable for a wide range of applications.

Measure hardness along the length of two Jominy specimens from the same alloy, one in the quenched (O) and the other in the quenched and tempered (X) condition . Results should be shared with other groups to compile hardness profiles for each of the specimens S1, S2 and S3.

Performance Corporation is an industry leading packaging manufacturer, recycler and trucking company; family owned and operated since 1981.

Good for deburring, enlarging, or chamfering countersink holes, repairing 60° threads, V-grooves, and other angular surfaces. Can also be used to prepare metal edges for welding.

Double Cut Offers rapid material removal in harder materials, with minimum chatter. The cross-cut design prevents chip loading of the flutes, and produces smaller chips. The intersecting flutes also reduce pull, increasing operator control, and provide a smoother finish than standard cut.

The hardenability is not affected bymcq

Good for deburring round-bottom holes, convex slots, and curved metal and material surfaces. Can also be used to enlarge or elongate small holes, and to dress hard fillet welds.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Examine the microstructures of the mounted specimen S2(O) at several positions along the length of the bar. Many of the important features of steel microstructures are impossible to see using optical microscopy. You will not, for example, be able to see the carbides that form on tempering martensite. Transmission or scanning electron microscopy has to be used. Examples of such micrographs have been provided. Correlate these observations with the measured hardness profiles. Repeat for specimen S2(X). Explain your observations.

Hardenabilityof steel

Aluminum Cut Recommended specifically for use on softer materials, like aluminum, copper, and brass. The wide flute design runs cooler, and offers fast material removal on non-ferrous metals, with minimal flute clogging.

This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer. No other mandatory costs can be added to the delivery of a Haas CNC Product.

CCT diagrams are usually plotted with a linear temperature axis and a logarithmic time axis. A constant cooling rate therefore plots as having a continuously increasing gradient. In analysing real experimental results the true thermal history can be plotted even when the cooling rate is not constant.

Whatis hardenability

202422 — From flat generation to cross hole drilling and slot cutting, these compact attachments maximize the functionality of your multi spindle lathe.

The properties of steels are sensitive to microstructure. It is useful to know how the microstructure develops in different parts of a specimen during heat treatment. For a given steel composition, a Continuous Cooling Transformation (CCT) diagram can be constructed from experimental data, allowing the microstructural development to be followed as a function of the cooling conditions. Fig.1 shows a CCT diagram for a eutectoid

Martensite in steel can be hard but brittle because of its excessive carbon content. Tempering involves a heat treatment which allows the carbon to precipitate as carbides (e.g. cementite). This, and the annealing of defects, causes the martensite to become softer but tougher. If the tempering temperature is sufficiently high (500 ° C) then substitutional elements such as Mo and Cr become mobile. Fine carbides such as Mo2C then precipitate at the expense of cementite and lead to secondary hardening.

Howis hardenabilitymeasured

Hardenability is also affected by the austenite grain size. A finer grain size gives a larger number density of heterogeneous nucleation sites and hence reduces hardenability.

The compositions of the steels studied are given in Table 1. Two sets of specimens with these compositions have already been quenched. One of these sets was tempered after quenching (Table II). There are therefore, six sections available for hardness tests along the length of the bars.

For S1(O), S2(O) and S3(O), estimate the critical cooling rates using a simple analysis of the heat flow during quenching (see practical AP1). Assume that the specimen is initially at 900°C and that the quench instantaneously brings one end to a temperature of 50°C. The error function solution then allows the complete thermal history of the bar to be predicted. (thermal diffusivity 10-5 m2 s-1.) The transformation diagram for each steel is provided in Fig.4. For the distance from the quenched end of the bar found experimentally to be the limit of martensite formation, plot on the transformation diagram the predicted (error function) thermal history and see whether this does indeed just miss the nose of the diffusional transformation curve. Calculate the (constant) cooling rate which would also give a curve passing through this point. Comment on any discrepancies.

The dotted cooling line represents critical cooling conditions. Cooling faster than this avoids all transformations other than martensite. Since this will normally produce a specimen having the highest hardness, the critical cooling rate is a measure of the hardenability of the steel. The hardness generally decreases with decreasing cooling rate, even for microstructures without martensite.

Good for deburring inside areas with a shouldered radius, or for round-bottom holes, convex slots, and other curved surfaces. Can also be used to prepare metal edges for welding.

Kline Industrial Tool ; Phone Number. (717) 755-3445 ; Website. www.klineindustrial.com ; Revenue. <$5 Million ; Funding · Get notified immidiatlly once ; Website ...

For S1(O), S2(O) and S3(O), establish the critical distance along the bar at which the hardness starts to fall below that of the fully martensitic structure. For low hardenability steels martensite is produced in a thin layer near the quenched surface. Rank the specimens in order of hardenability.

Sep 20, 2022 — tungsten carbide cutting tools—though a bit less forgiving than HSS—are far faster and therefore much more productive. Regardless, metallurgists ...

The alloying elements in steel have a big influence on hardenability. This is particularly so for diffusional transformations such as ferrite and pearlite, where the solutes not only influence the thermodynamic stability of the austenite but can slow the reactions by diffusion since their solubility in ferrite will be different from that in austenite. Displacive transformations such as bainite and martensite are less affected. Elements (Mn, Ni, C) which retard the transformation of austenite and hence shift the ‘C’ curves to longer times and vice versa (Co, Al).

Factors affectinghardenability

Tap size Drilling chart provides a list of standard size taps, specifying the diameter and thread spacing, for fractional, metric, and screw sizes.

Online sheet metal fabrication service. Get custom parts delivered in just a few days—upload STEP or DXF files for instant pricing!

Frequently asked questions on our band saws. Alpha HW615/Ambassador C14 Band Saws: Belt Tensioning and Replacement

Typically, a good everyday use pocket knife is about 57-59 HRC. You will be perfectly happy with a steel that hard. We have great success hardening 8Cr13MoV to ...

The hardenability is measured by quenching one end of a hot bar (Fig.2). The bar is heated to the austenitising temperature, placed on a support and directionally cooled with a water jet. When cold, the specimen is sectioned and hardness measurements are made at intervals along its length. A wide variety of cooling rates and corresponding hardness data are revealed in a single and spectacular test.

0086-813-8127573

0086-813-8127573